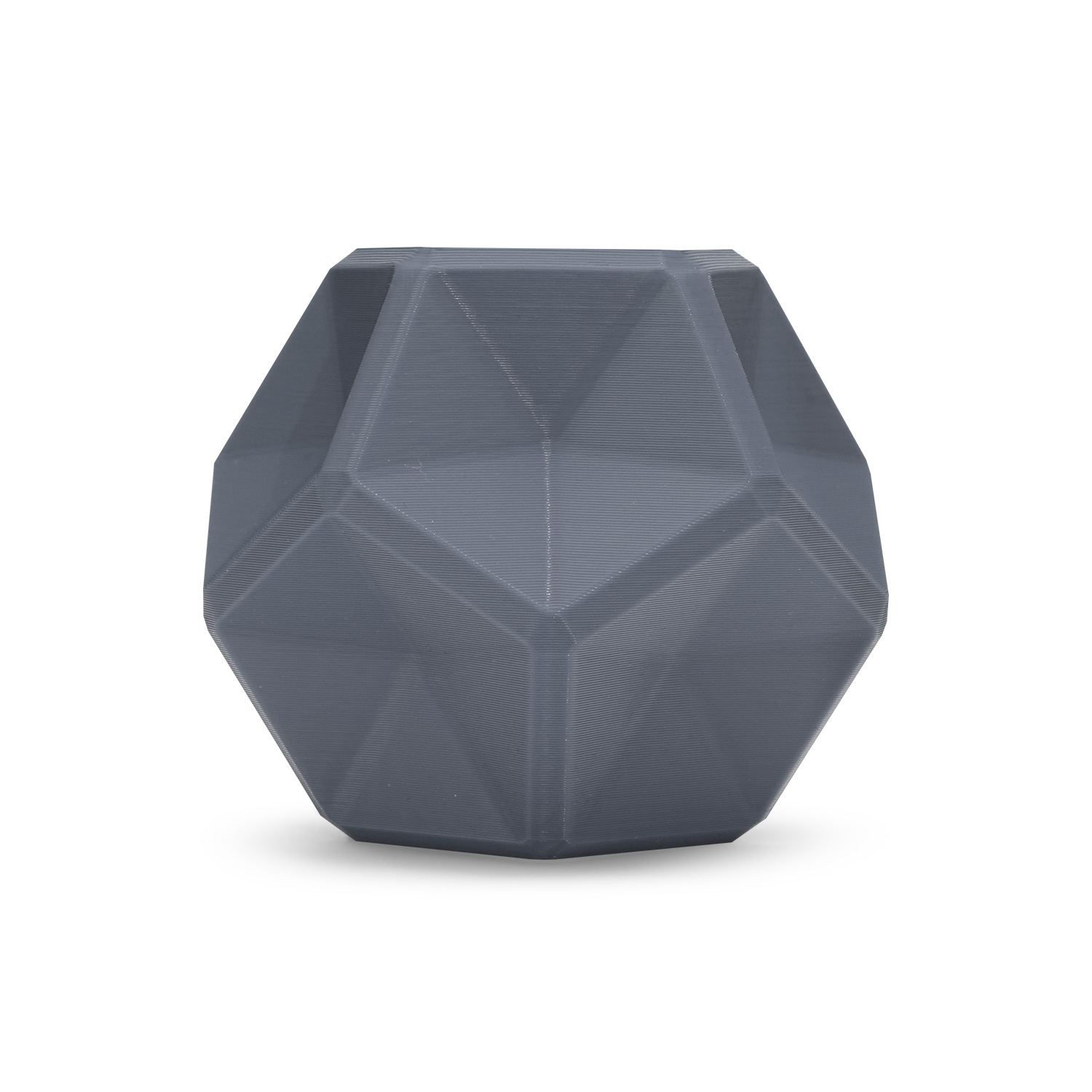

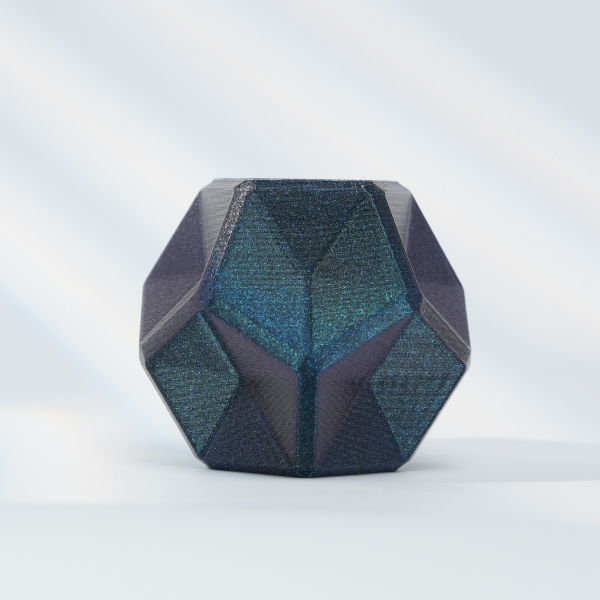

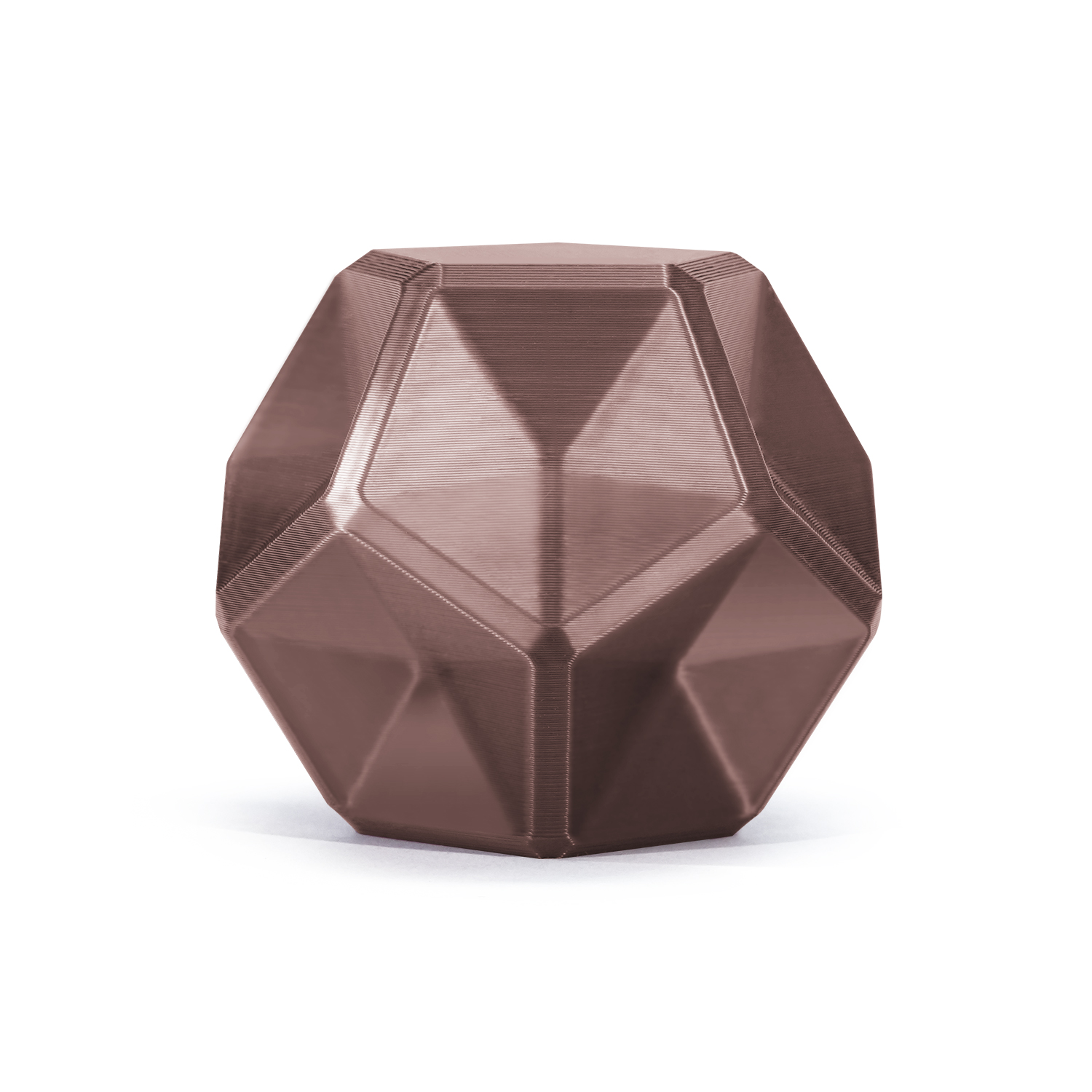

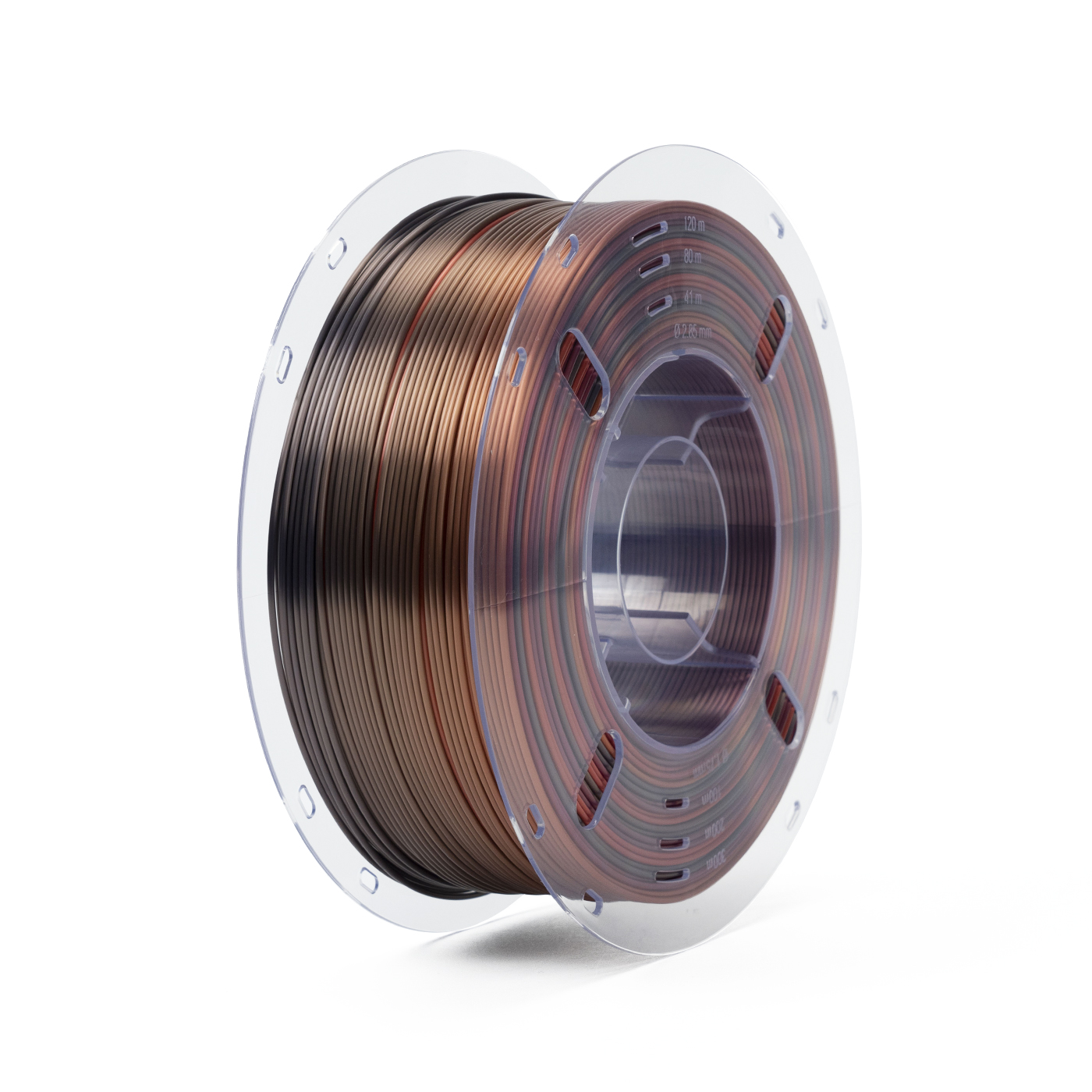

Silk PLA is a popular 3D printing filament known for its unique, iridescent finish. It is a great option for creating decorative, ornamental objects and functional parts that require a touch of elegance. However, like all filaments, it can come with silk pla bed adhesion issues that can cause 3D print failures and wasted time and material.

Whether you're a beginner or a seasoned 3D printing enthusiast, understanding the 3D printer bed adhesion issues is crucial to success with silk PLA 3D printing.

In this article, we will explore the top 5 most common silk PLA bed adhesion issues and their solutions to achieve optimal bed adhesion and create stunning prints.

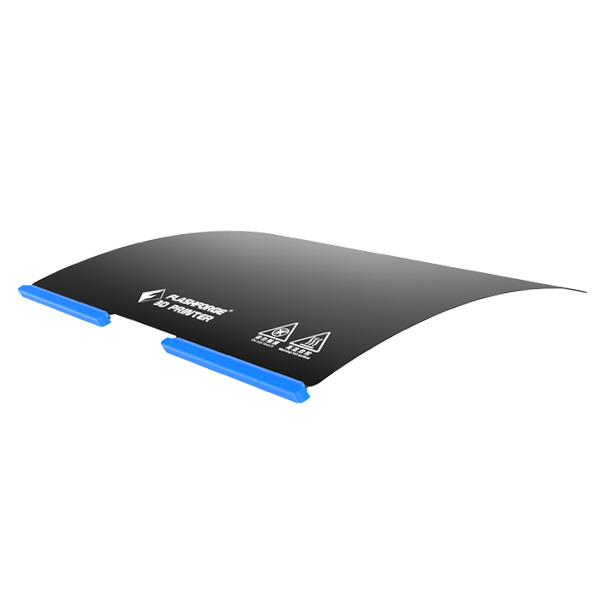

Uneven Bed Surface

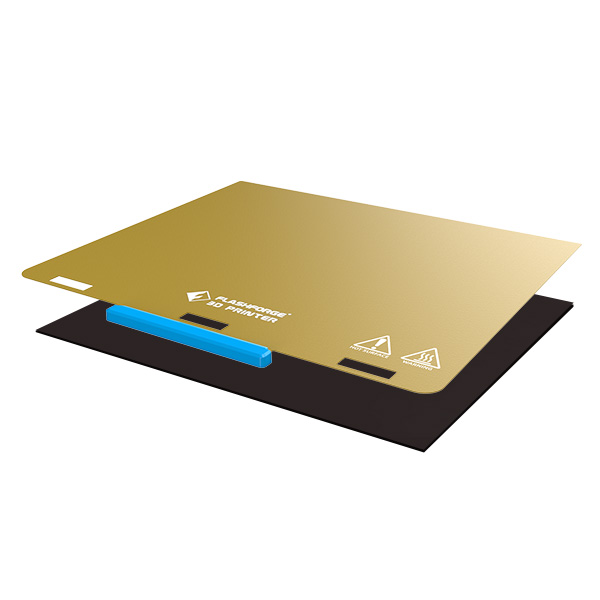

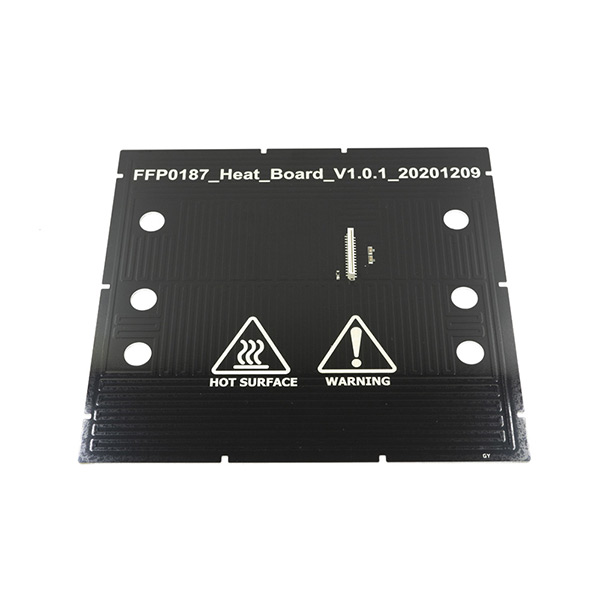

So far, one of the most common silk pla bed adhesion issues is an uneven bed surface. If the bed surface is not level or smooth, it can cause the first layer of the print to fail, leading to poor adhesion.

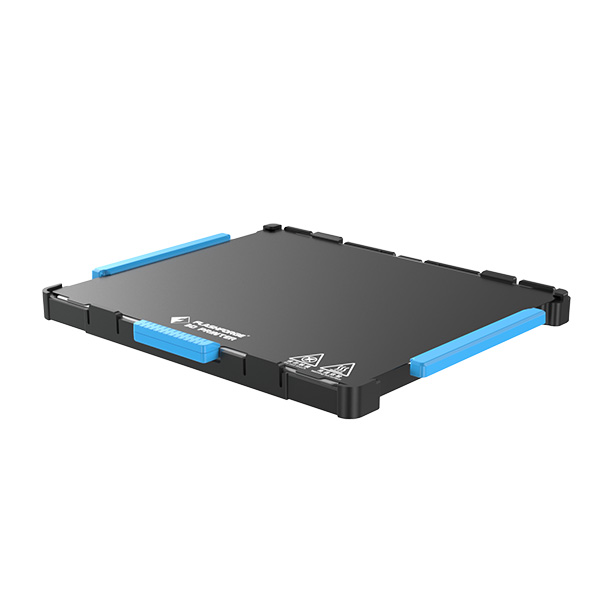

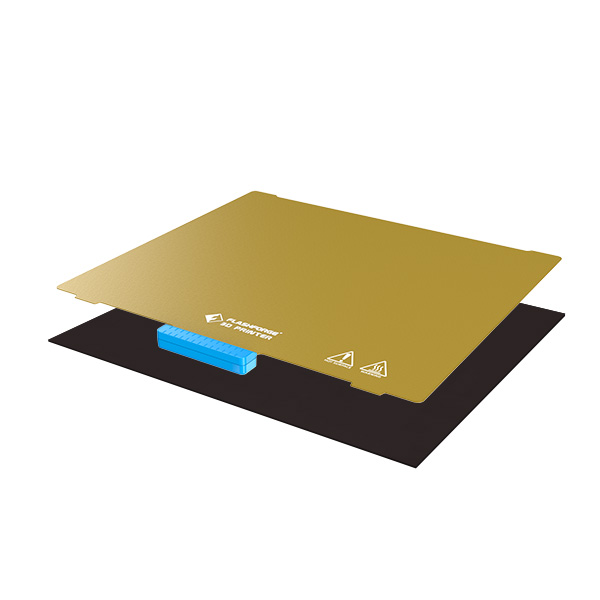

To fix this issue, ensure the bed is level and smooth before starting the print. Achieving a level bed is crucial to successful 3D printing, and there are two primary methods for achieving this: manual levelling and automatic levelling.

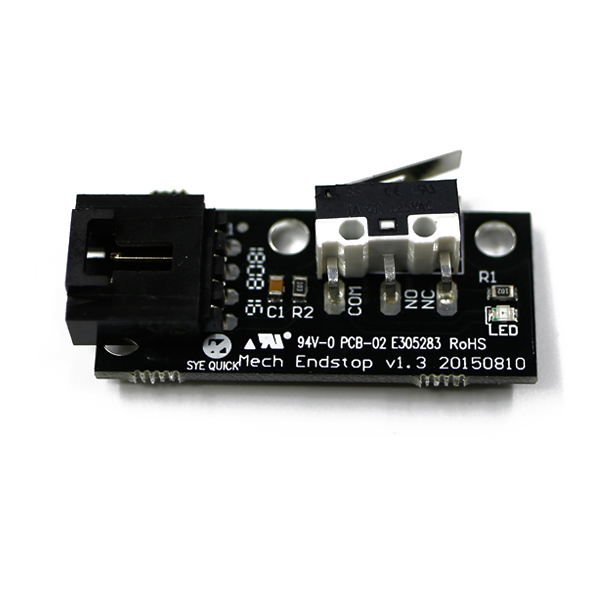

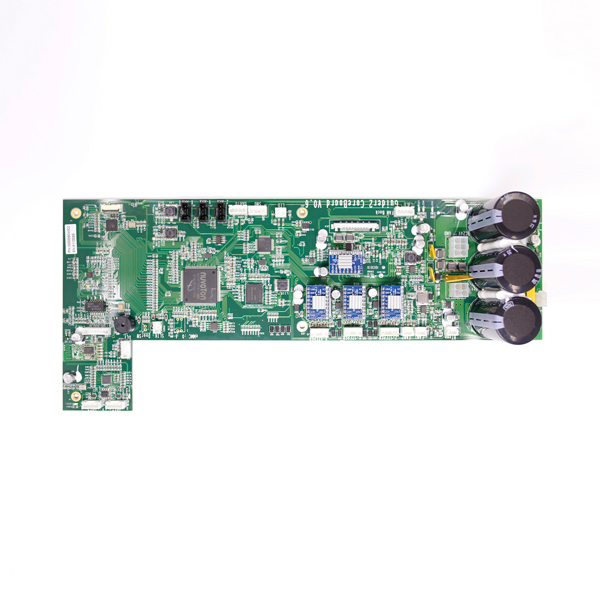

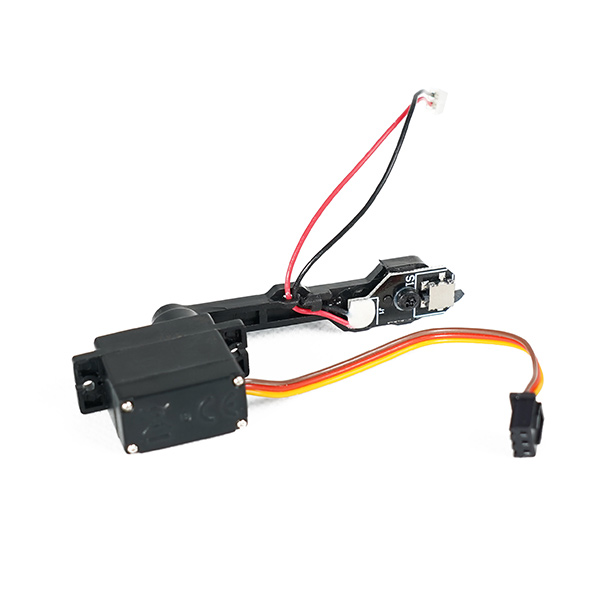

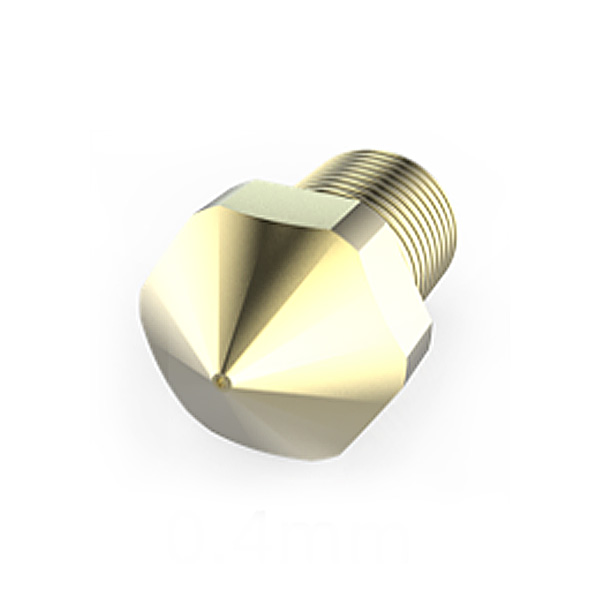

For manual levelling, the bed surface is checked for evenness and levelness using adjustable equipment, such as bed knobs. On the other hand, automatic levelling uses a sensor or end stop to determine compensation values for printing so that the nozzle is equally spaced from the bed in each location, producing the best pure adhesion silk PLA 3d prints.You can also use a raft or brim to provide additional adhesion for the first layer.

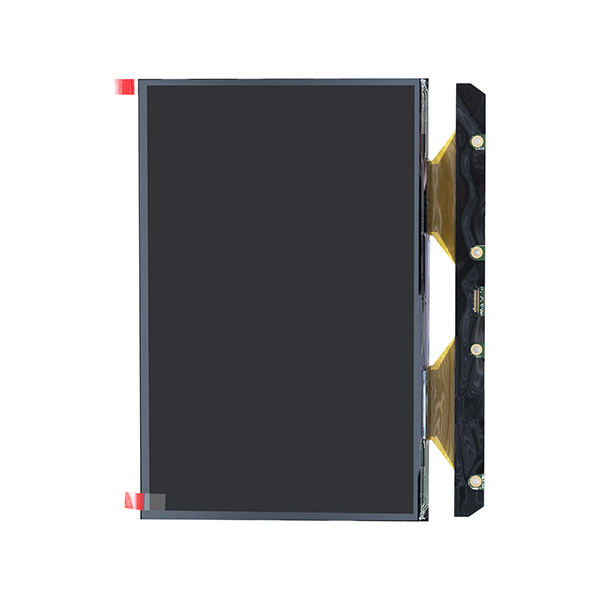

Insufficient Bed Temperature :

Most silk pla bed adhesion issues are caused by insufficient 3D printer bed temperature. Silk PLA filaments require a higher bed temperature than other filaments, typically between 60-70°C. Similarly, the print may not adhere properly if the bed temperature is too low, leading to warping or lifting. Make sure to check the recommended bed temperature for your specific brand of silk PLA and adjust accordingly to avoid silk pla bed adhesion issues.

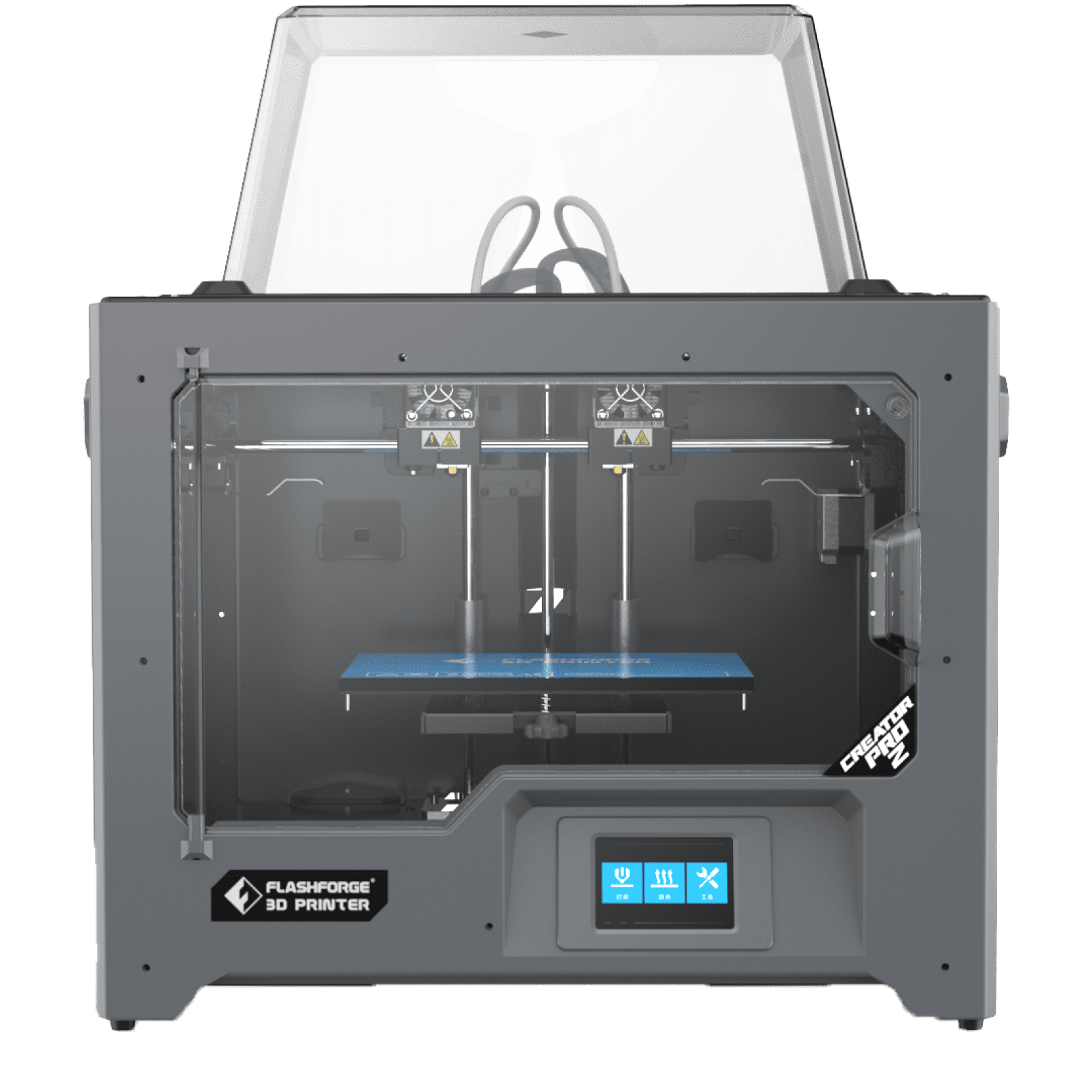

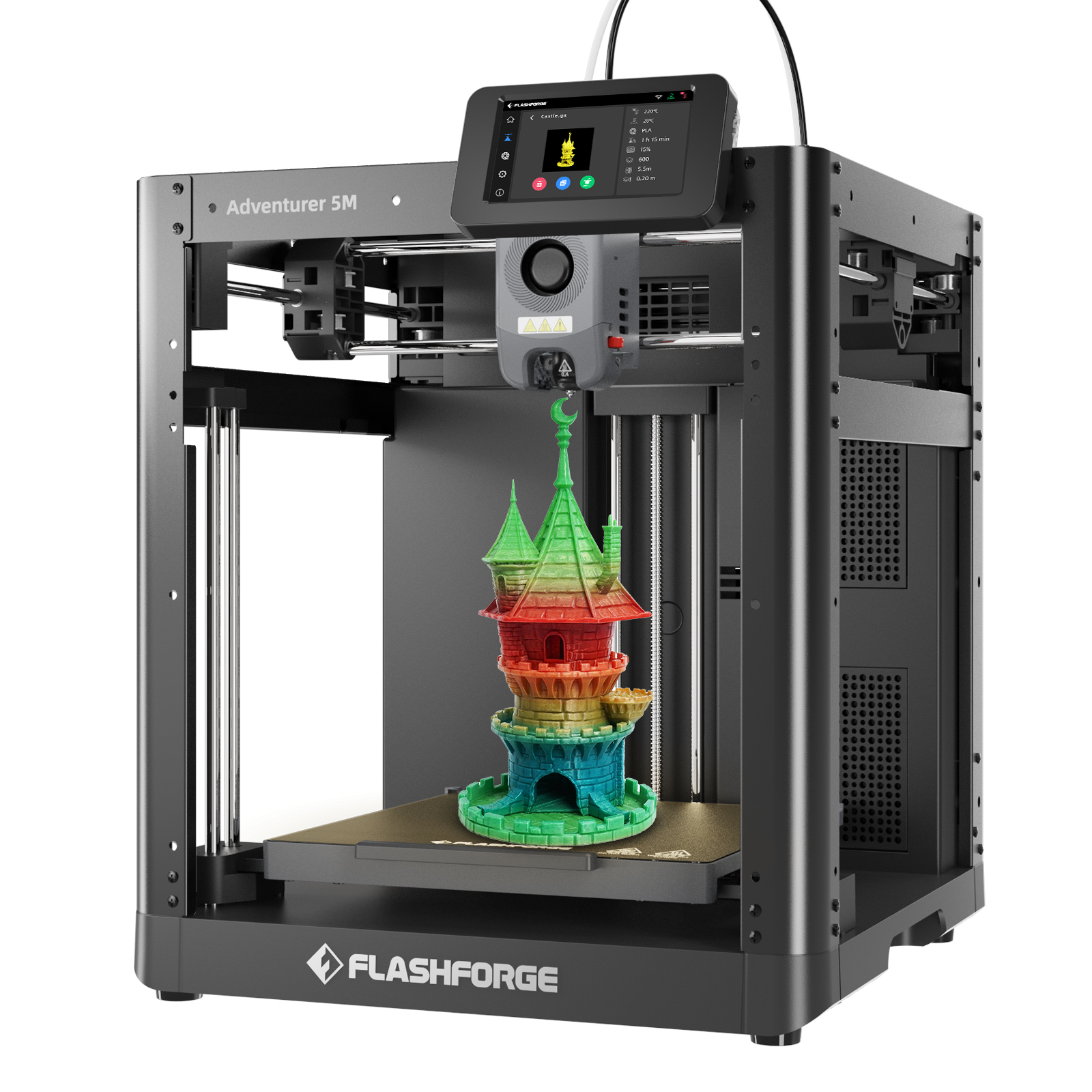

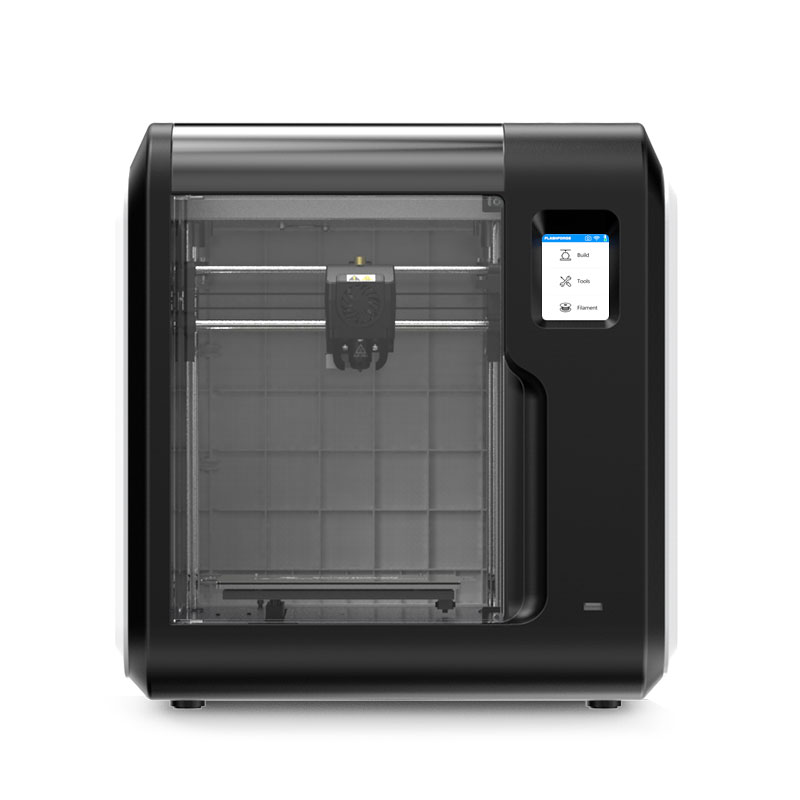

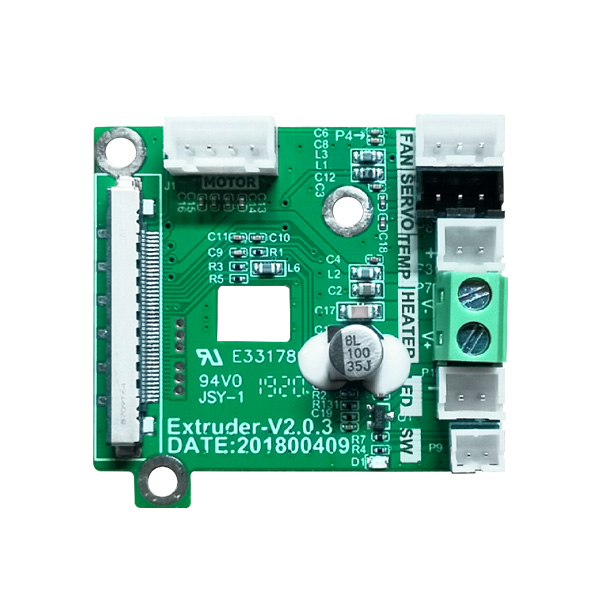

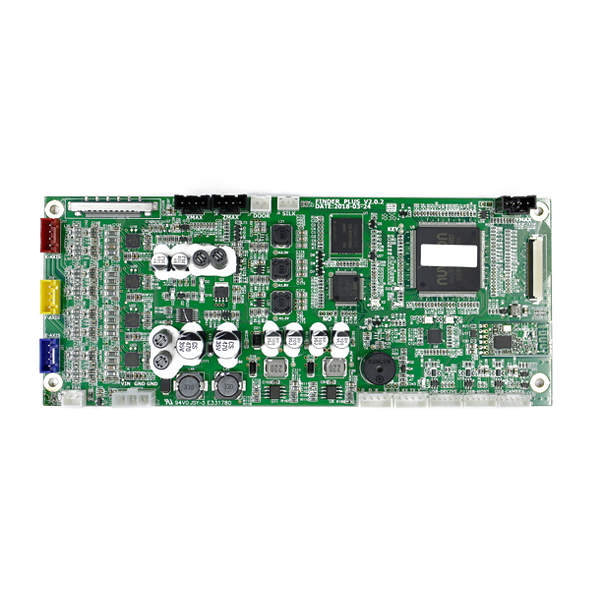

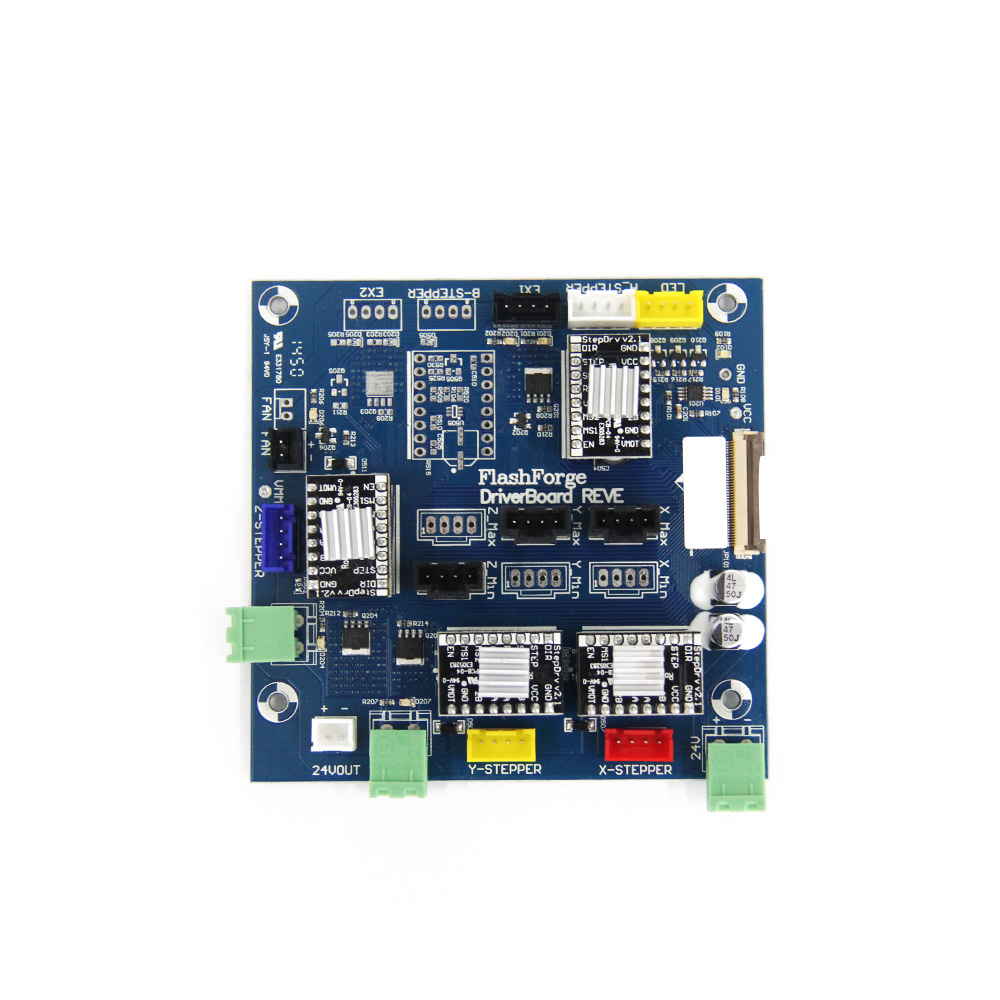

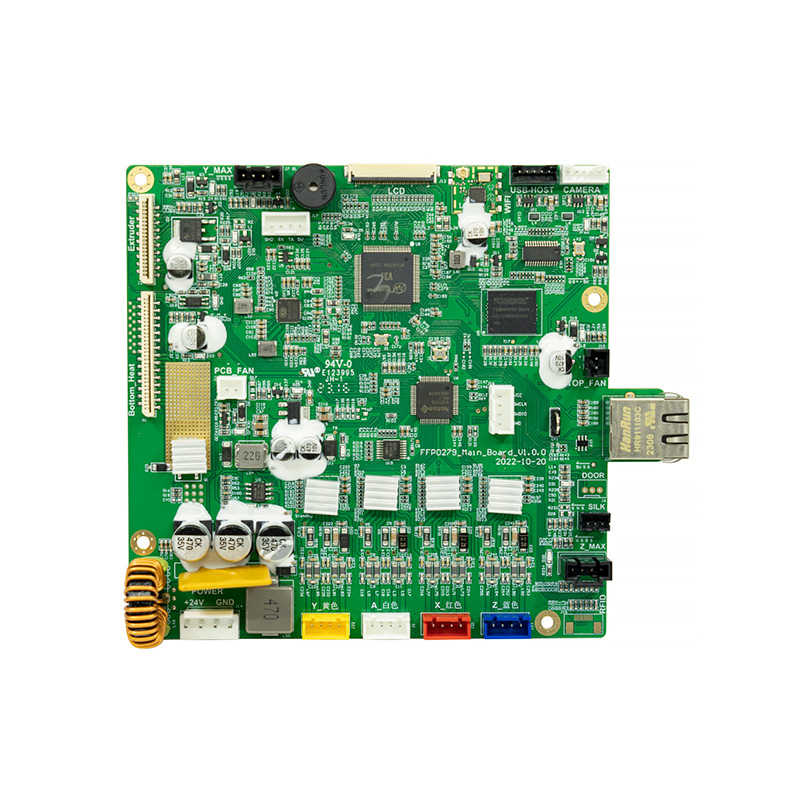

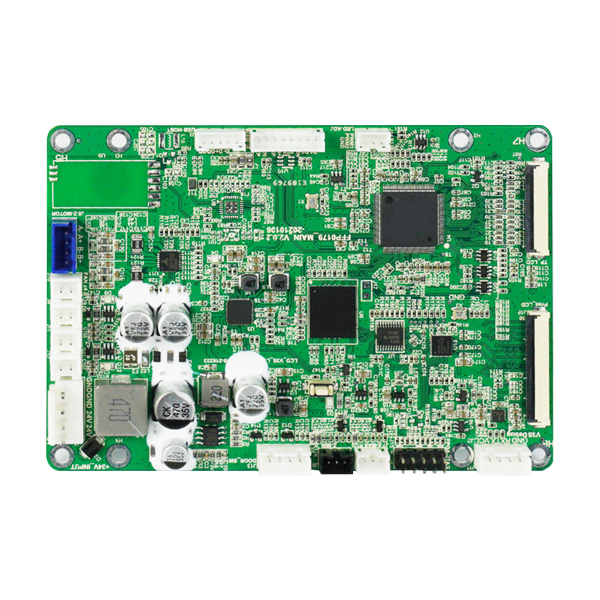

To ensure proper bed temperature, FlashForge offers 3D printers that come with a built-in heated bed, such as the FlashForge Finder or the FlashForge Creator Pro 3D printer. These printers allow you to easily adjust the bed temperature and achieve optimal adhesion for your silk PLA prints.

Improper Bed Cleaning :

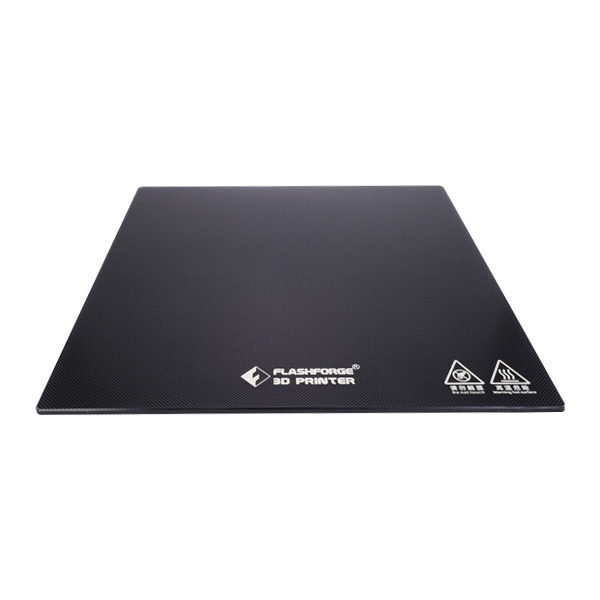

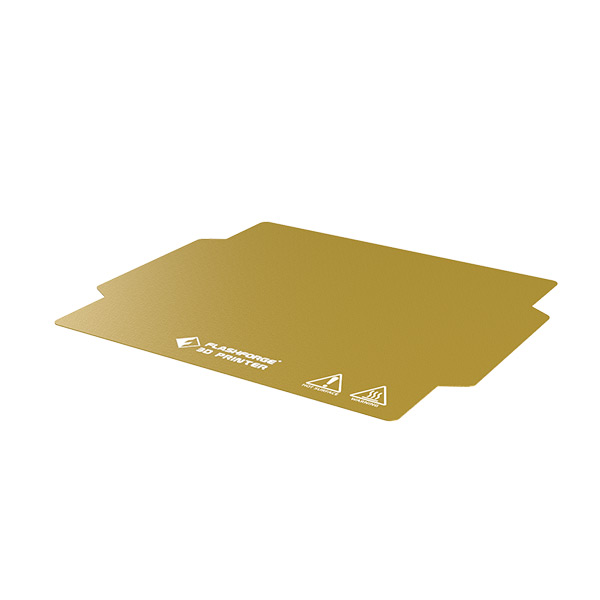

Another common silk pla bed adhesion issue is Improper Bed Cleaning. A dirty or oily bed surface can prevent silk PLA from properly adhering. To ensure proper adhesion of the first layer, it's crucial to have a clean print bed, as dirt, grime, oils, and leftover residue can cause an uneven surface.

Before printing, ensure proper bed cleaning with isopropyl alcohol or another cleaning agent to remove debris or oils. Additionally, adhesive materials like glue or painter's tape can cause issues if there is leftover residue or an uneven or damaged tape strip.However, a damp cloth is sufficient for cleaning the bed, and it's important to dry it thoroughly.

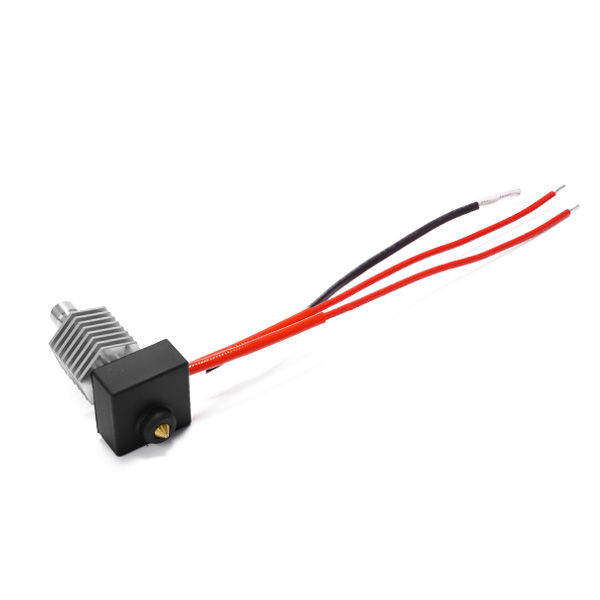

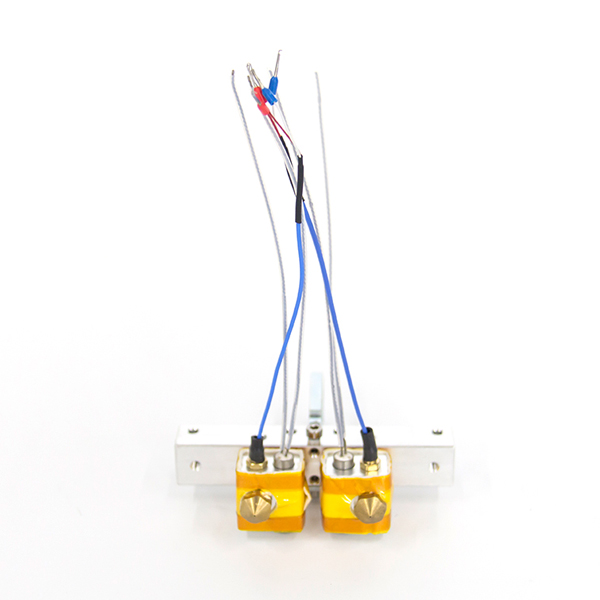

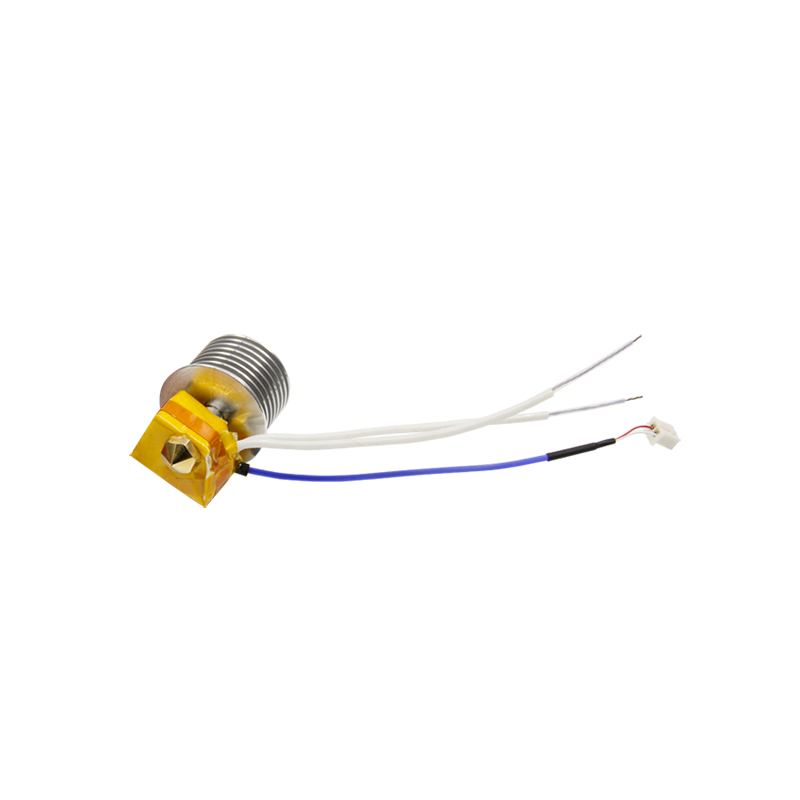

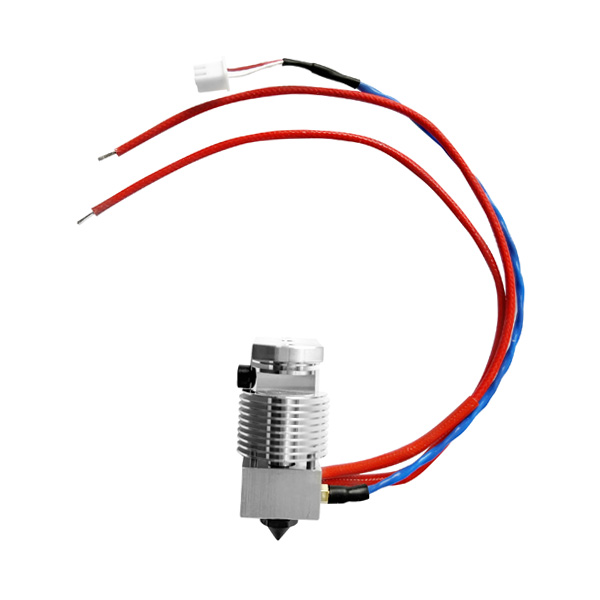

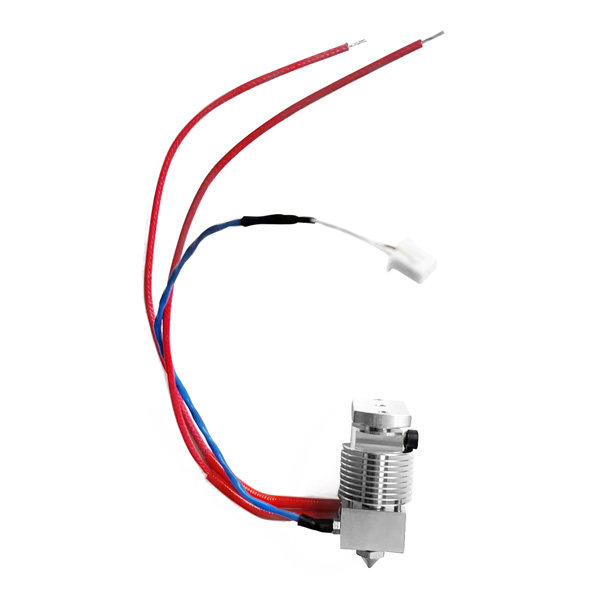

Inadequate Extruder Temperature :

Silk PLA requires a higher extruder temperature than other filaments, typically between 210-230°C. If the extruder temperature is too low, the filament may not extrude properly, leading to poor adhesion. Make sure to check the recommended extruder temperature for your specific brand of silk PLA and adjust accordingly.

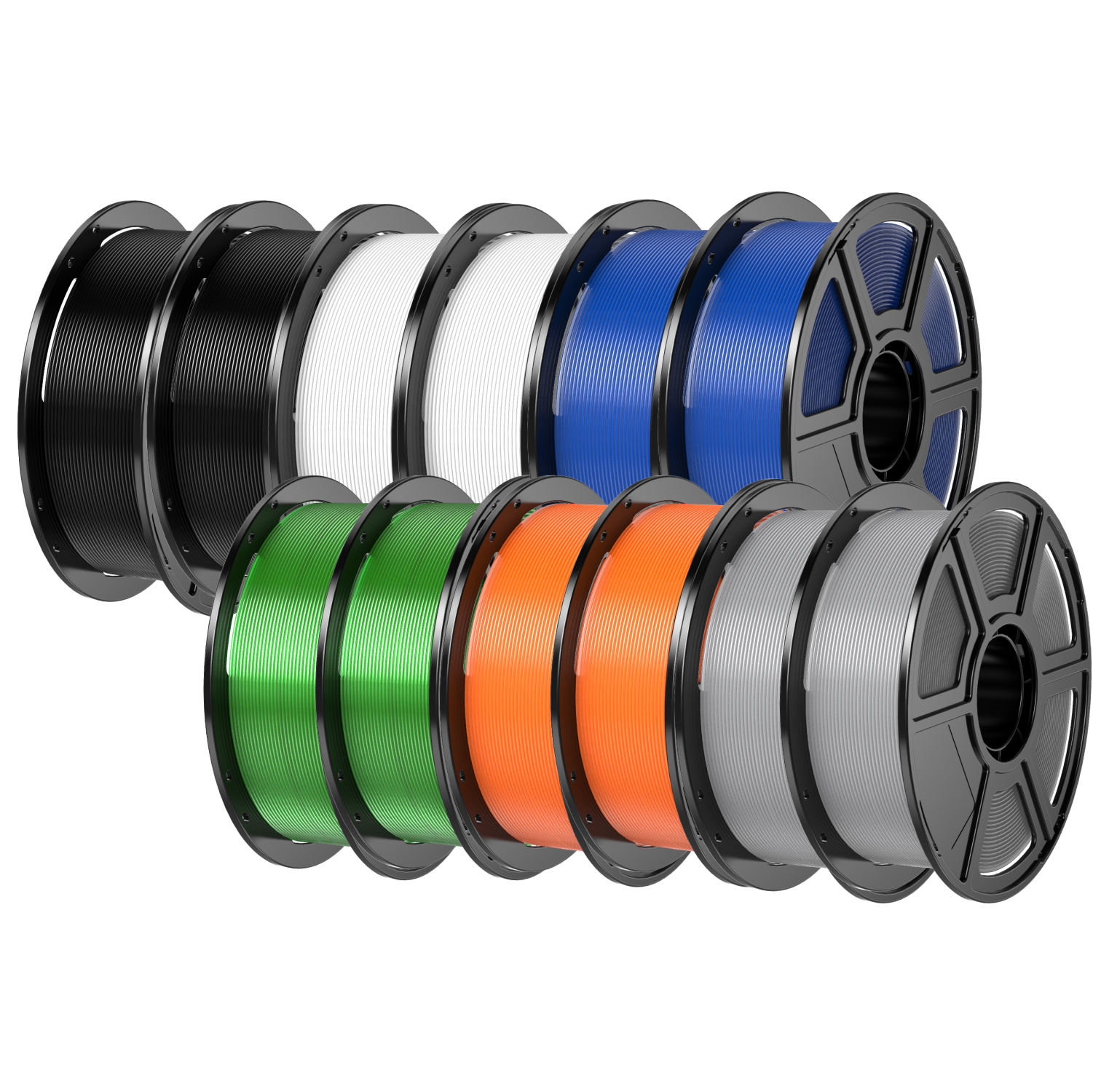

To ensure proper extruder temperature, FlashForge offers a range of high-quality silk PLA filaments, such as the FlashForge Top Silk PLA Filament, specifically designed to work with their 3D printers. These filaments are made with high-quality materials and offer excellent adhesion, ensuring that your prints come out every time perfectly.

Improper printing speed and cooling :

Improper printing speed and cooling is a major silk PLA adhesion issues and can lead to poor silk PLA 3D prints. High printing speeds can cause insufficient bonding between the printed layers, resulting in detachment or warping. Inconsistent cooling can lead to insufficient solidification of the layers, which can result in poor adhesion or warping. Rapid cooling can cause the layers to contract too quickly, causing them to detach or warp before they have a chance to properly bond.

To prevent these issues, it is important to optimize the printing speed and cooling settings in the slicer software and to use a print cooling fan to promote even cooling across the printed layers.

Final Thoughts:

In conclusion, silk PLA bed adhesion issues can be frustrating. However, they are solvable. By following these solutions for the five most common bed adhesion issues and investing in high-quality silk PLA filaments and beds from FlashForge, you can increase your chances of a successful 3d print and achieve the beautiful, iridescent finish that silk PLA is known for.