It is possible to use a 3D printer to print the parts needed to build another 3D printer. This is known as "self-replication" or "self-replicating machines". However, it may not be possible to create all the components required to build a 3D printer.

3D printed 3D printer is a fallacy

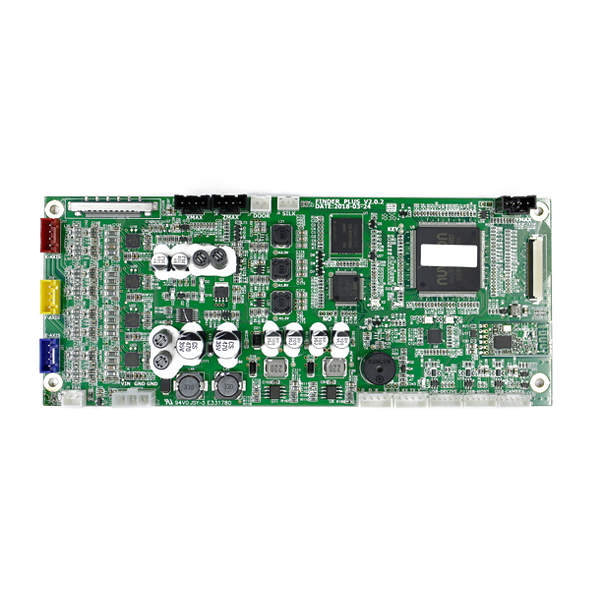

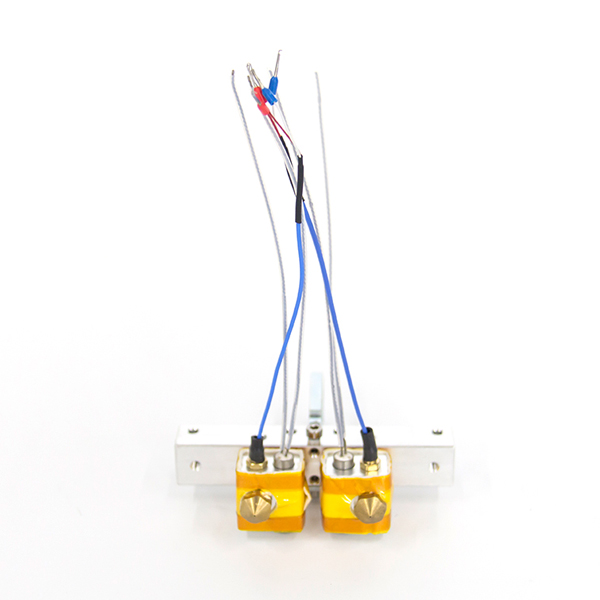

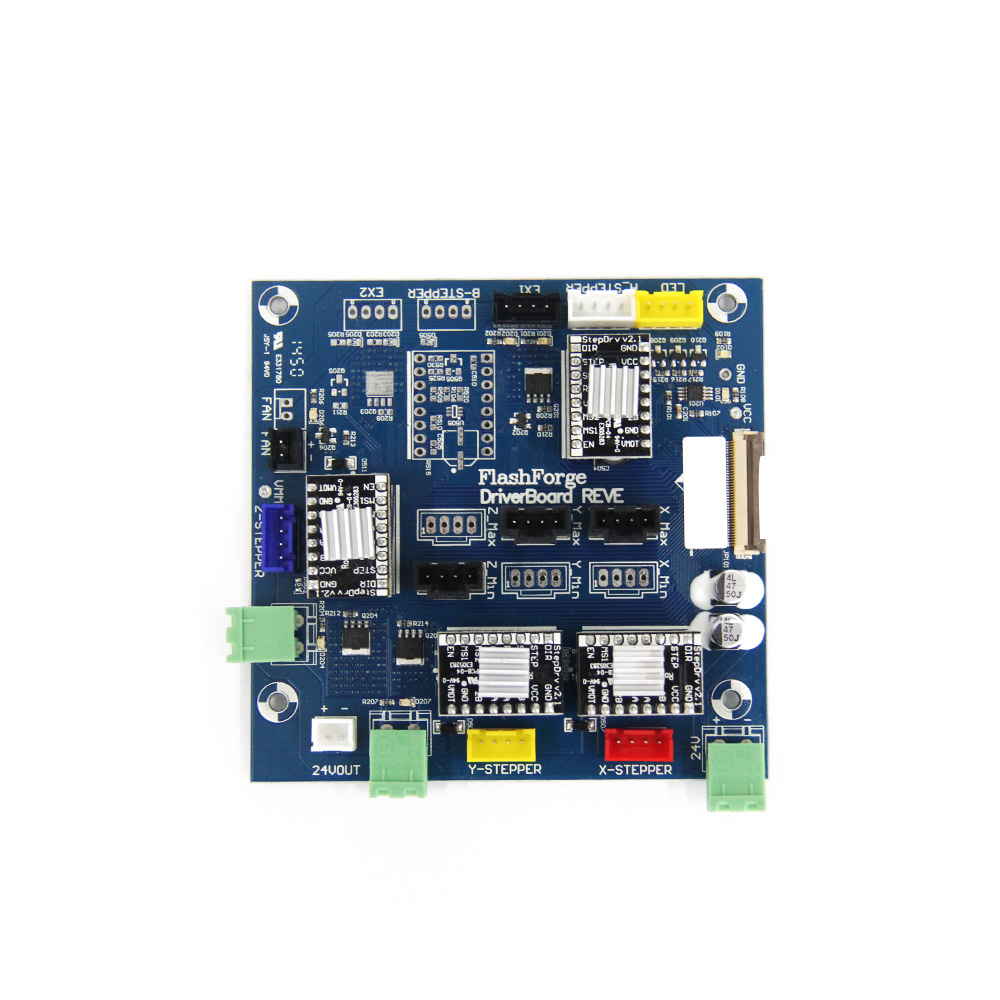

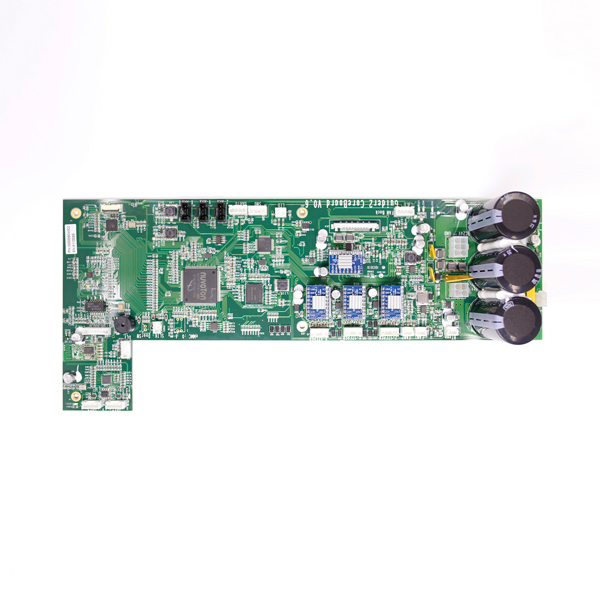

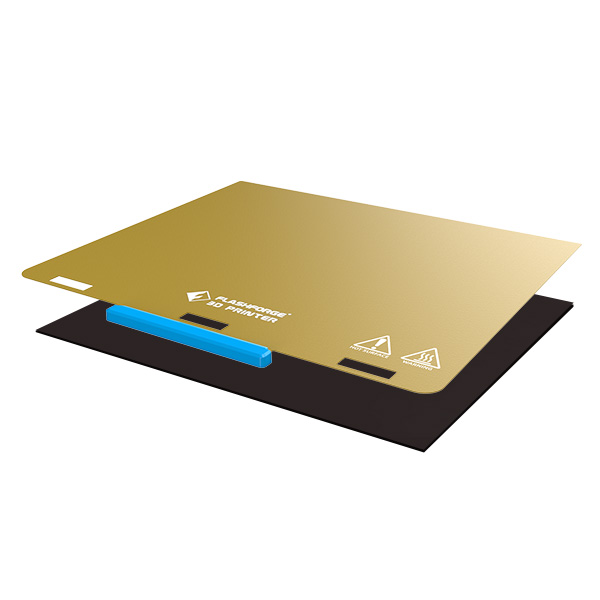

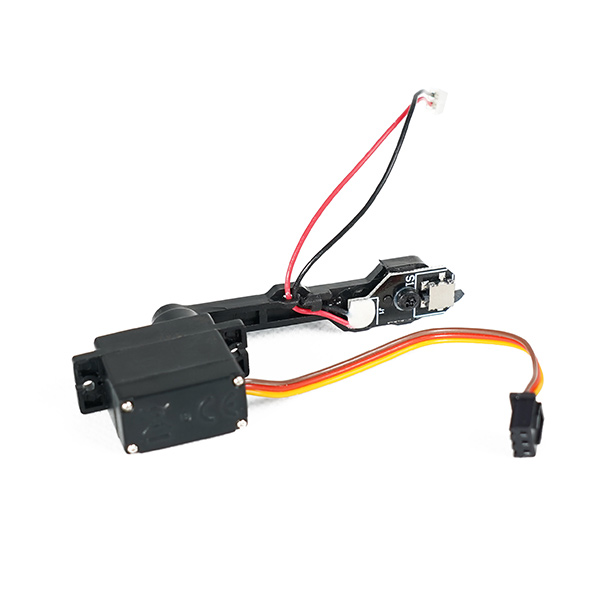

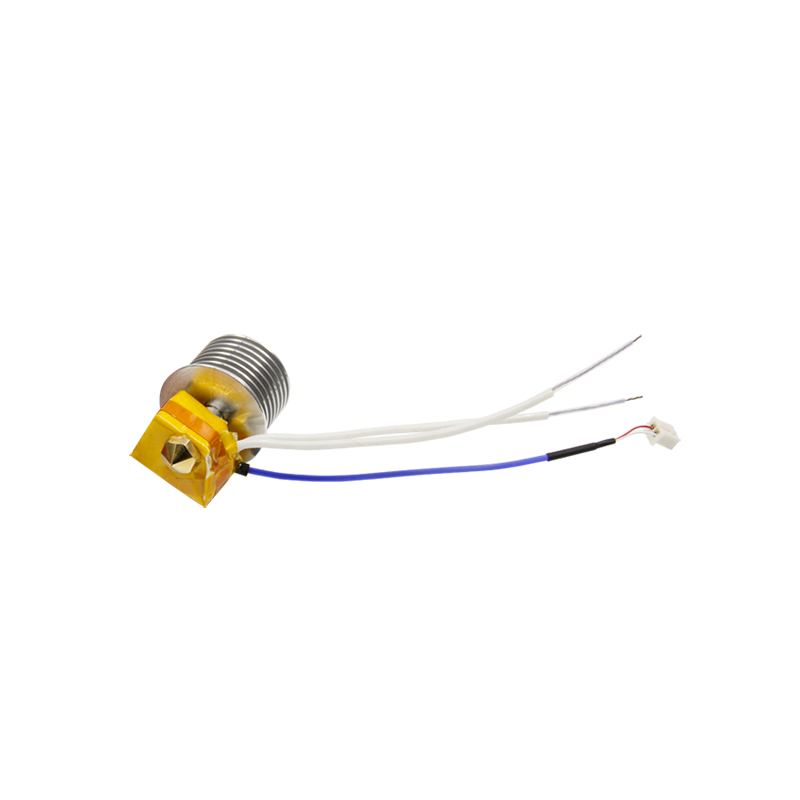

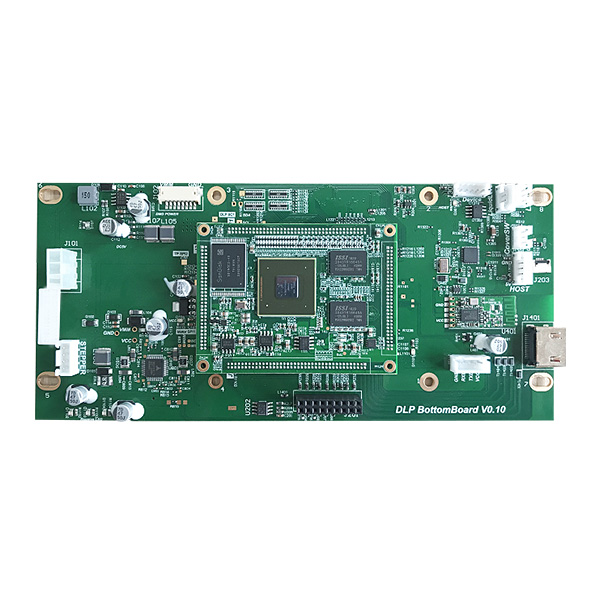

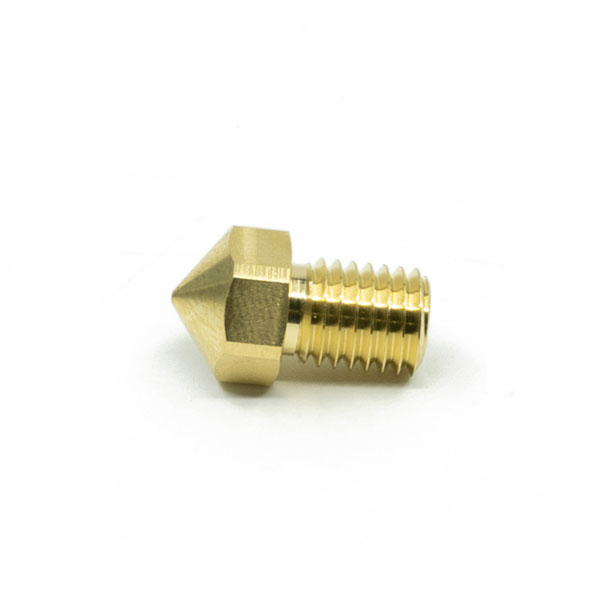

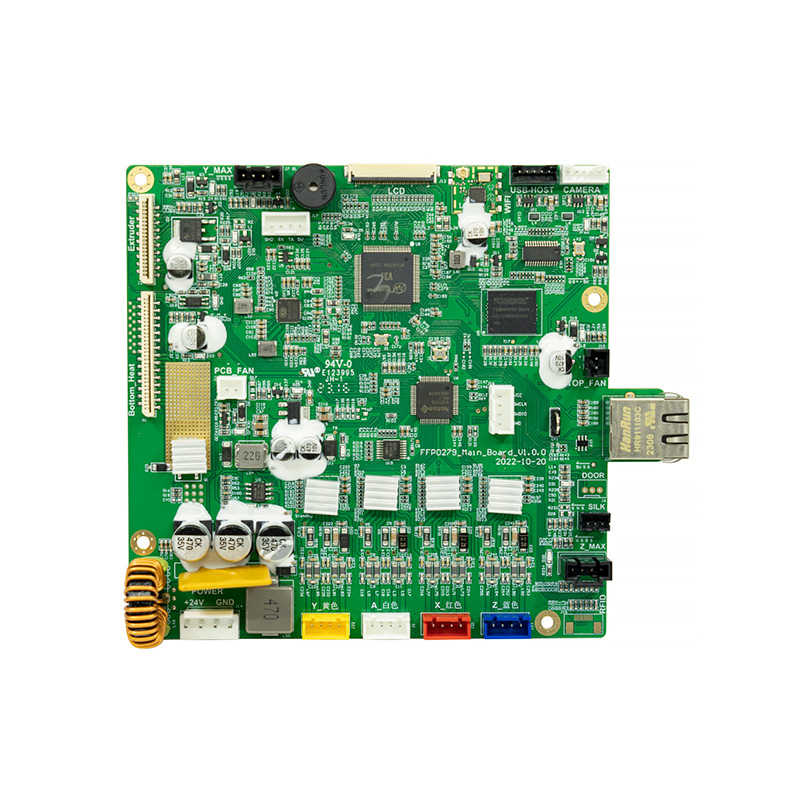

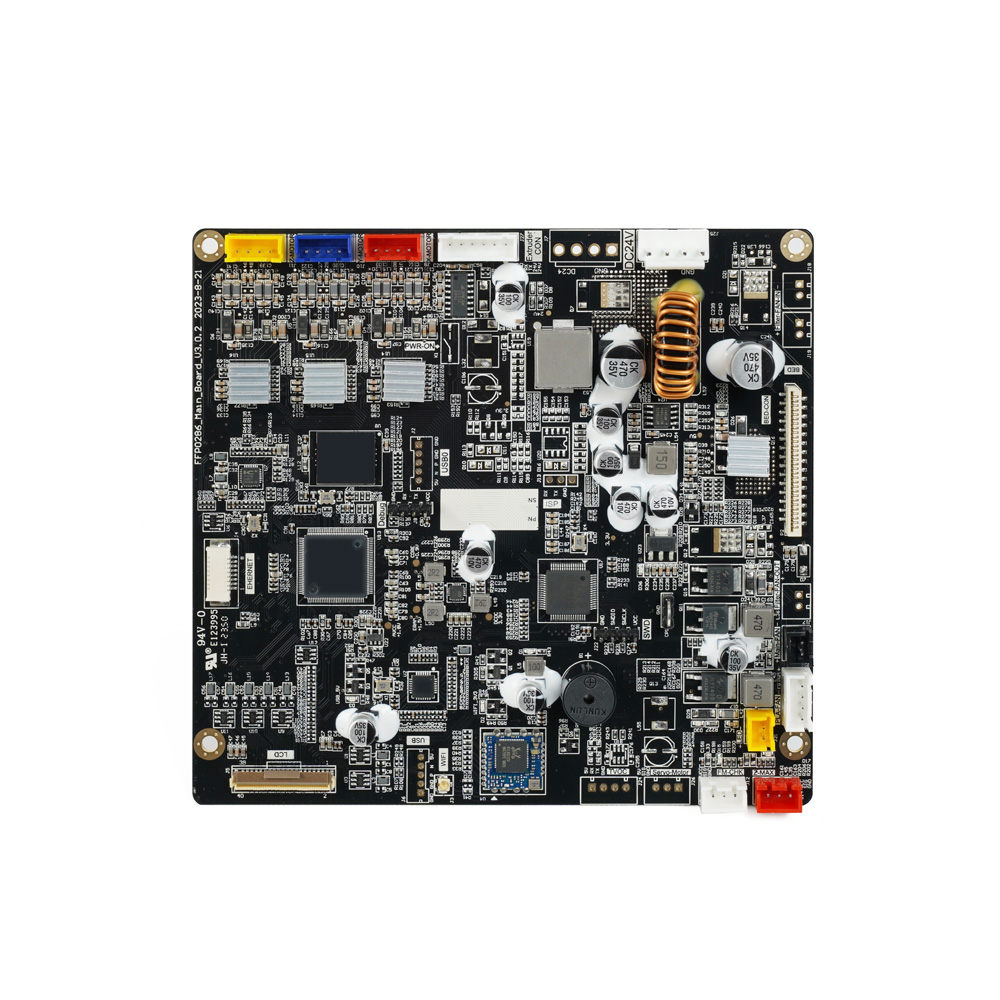

A really usable 3D printer involves not only structural framework, but also engineering function fulfilled by assemblies like nozzles, fans, steppers, motherboards, motors, electrical lines, lead screw, metal rods, and so on. Structural parts can be 3D printed by a 3D printer, but those engineering and electronic assemblies are not 3D printed, but purchased separately.

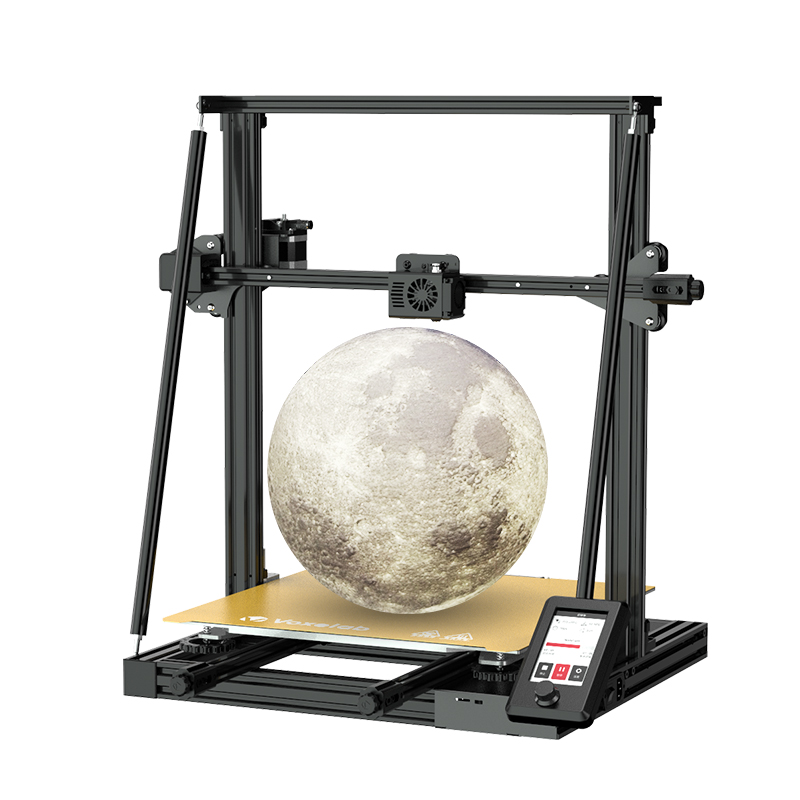

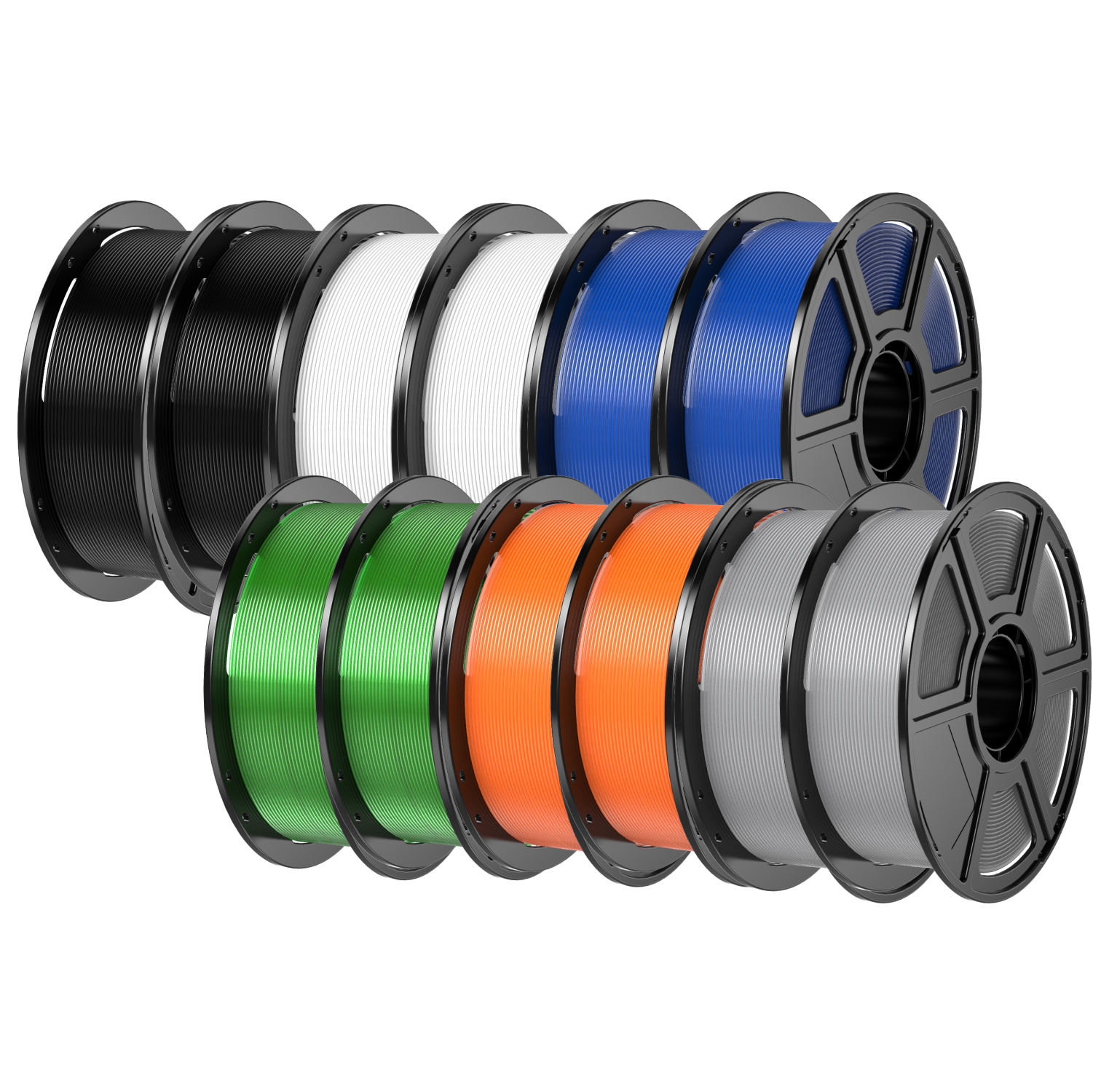

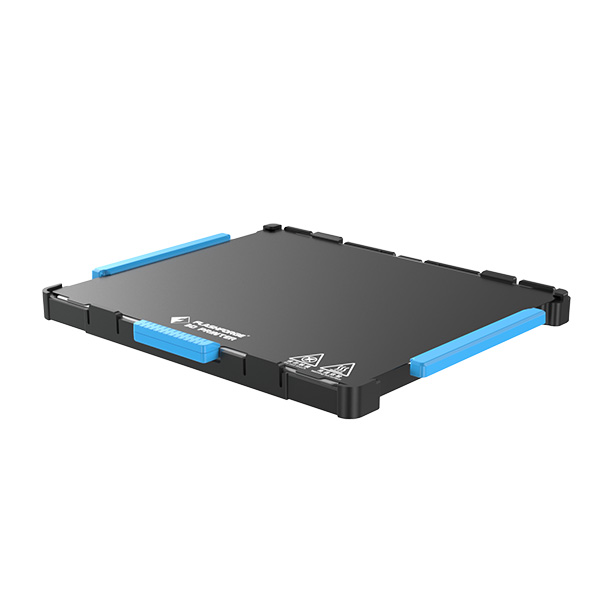

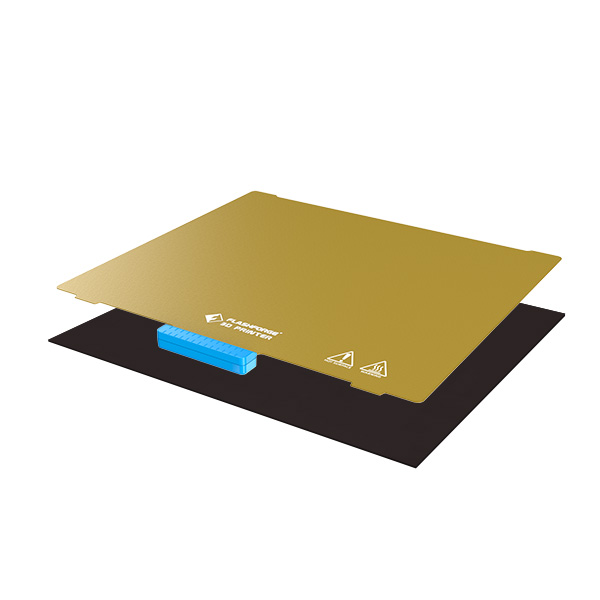

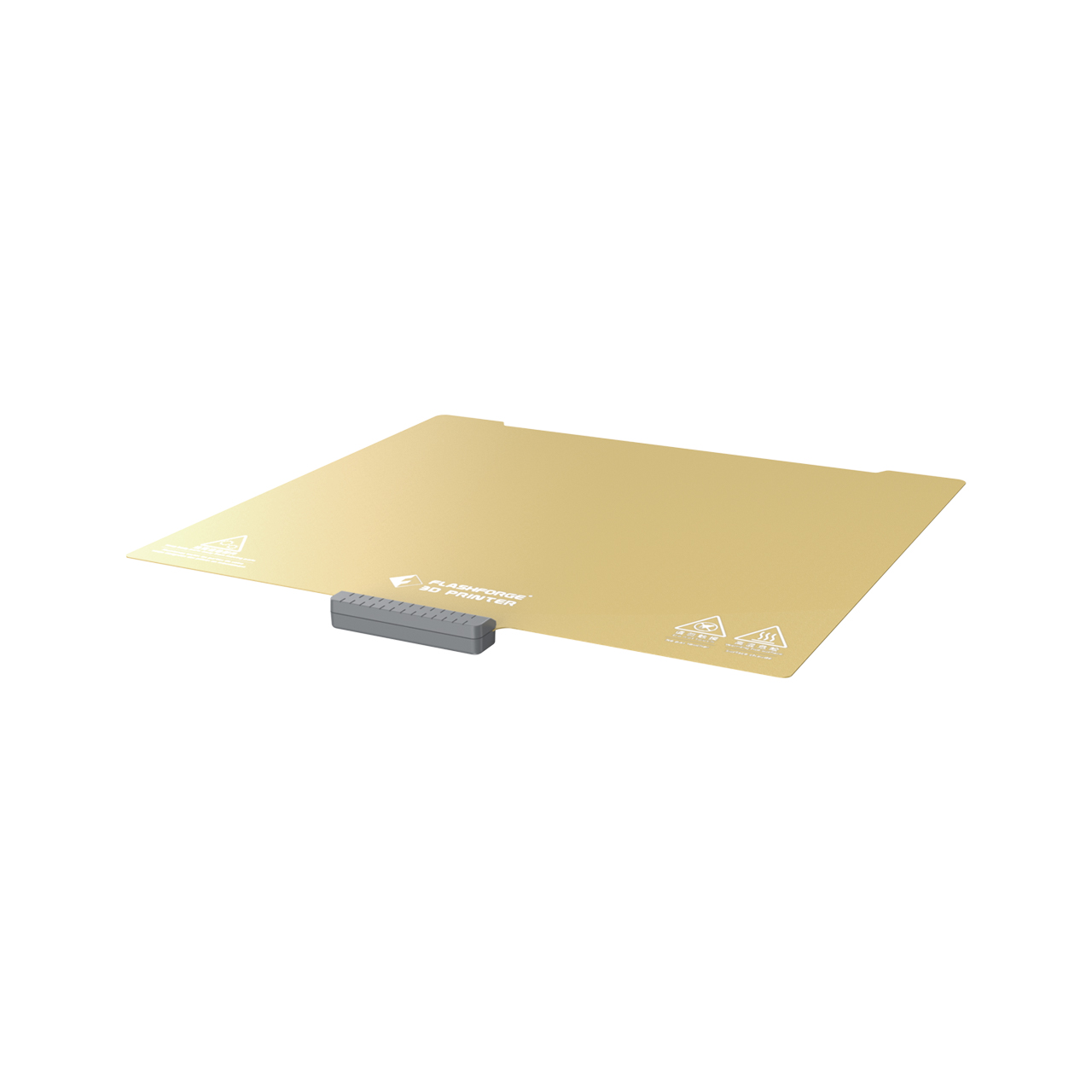

▲What you can 3D print for a 3D printer

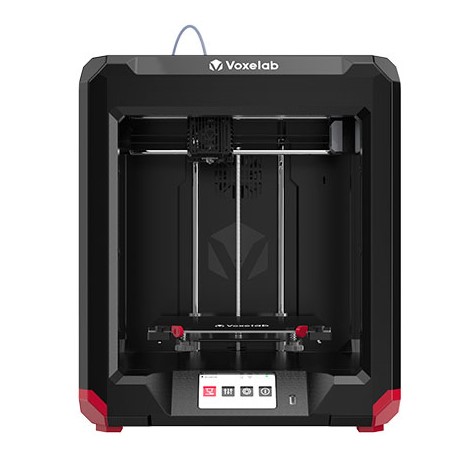

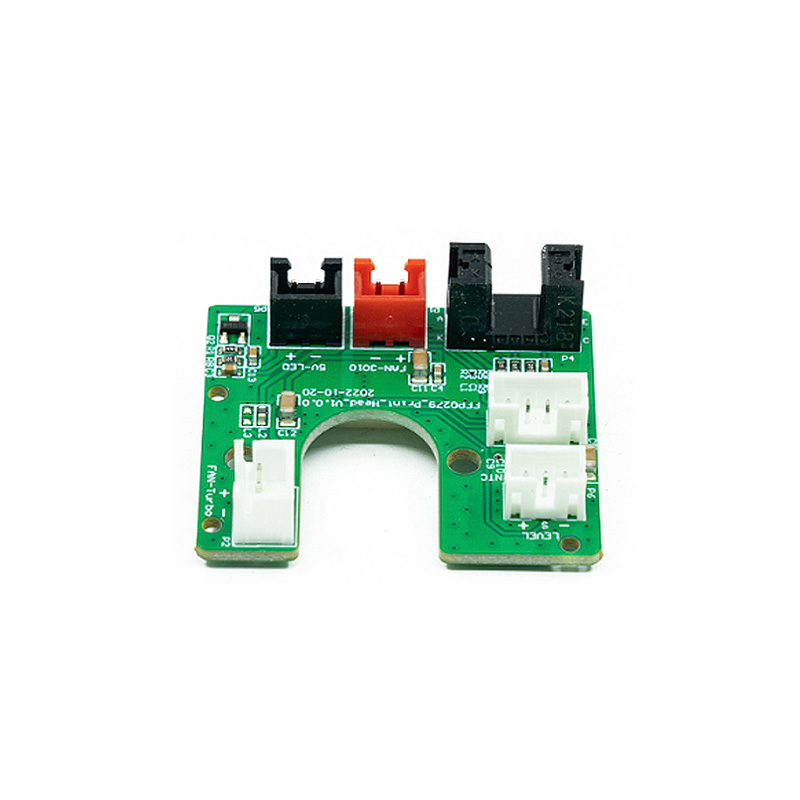

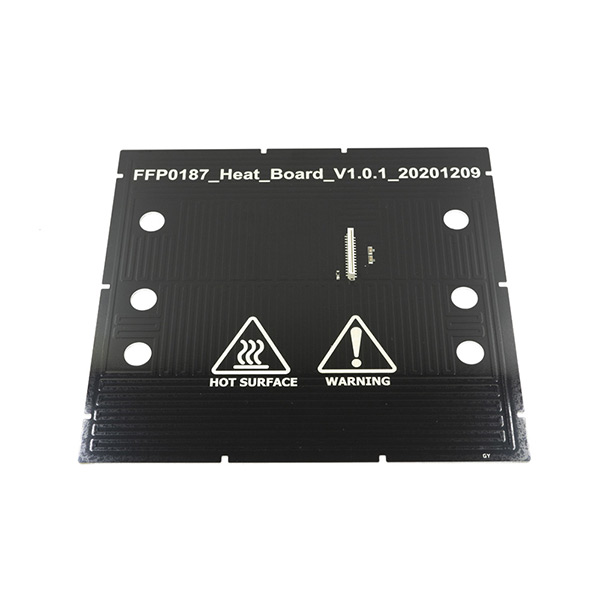

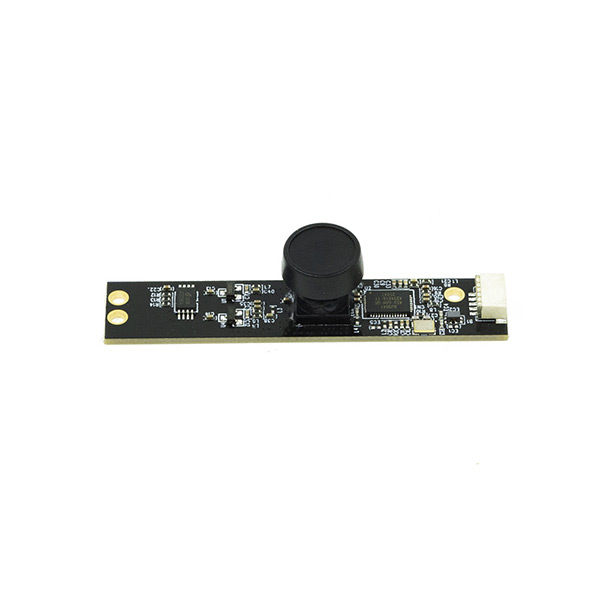

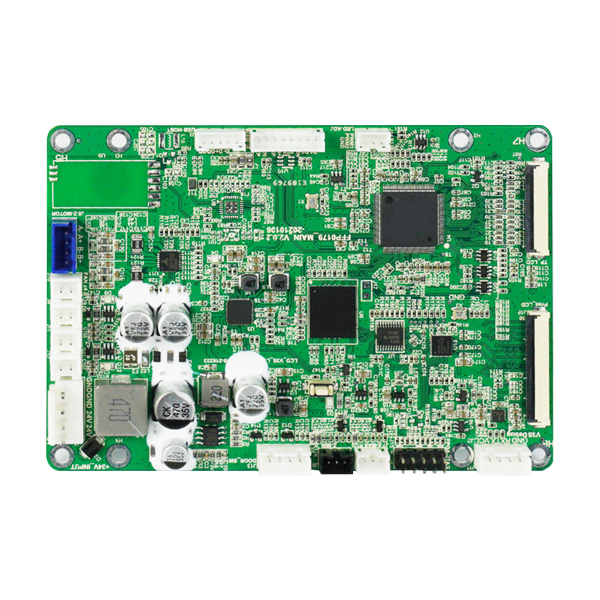

▲What you cannot 3D print for a 3D printer

So when you hear people say a 3D printed 3D printer, it means they 3D printed some parts and those parts were used to assembly a 3D printer. And, a fact is that when you get ambitious enough to 3D print a practically usable 3D printer, that means the time when you are reaching the level of a mechanical engineer knowing how to assembly a 3D printer!

Some real cases of 3D printed 3D printers

You 3D printed plastic parts and then get ready to assemble them with those engineering and electronic parts. Let’s just call such assembly result as 3D printed 3D printer. See some real examples now!

Case 1: 3D printed Adventurer 3 3D printer

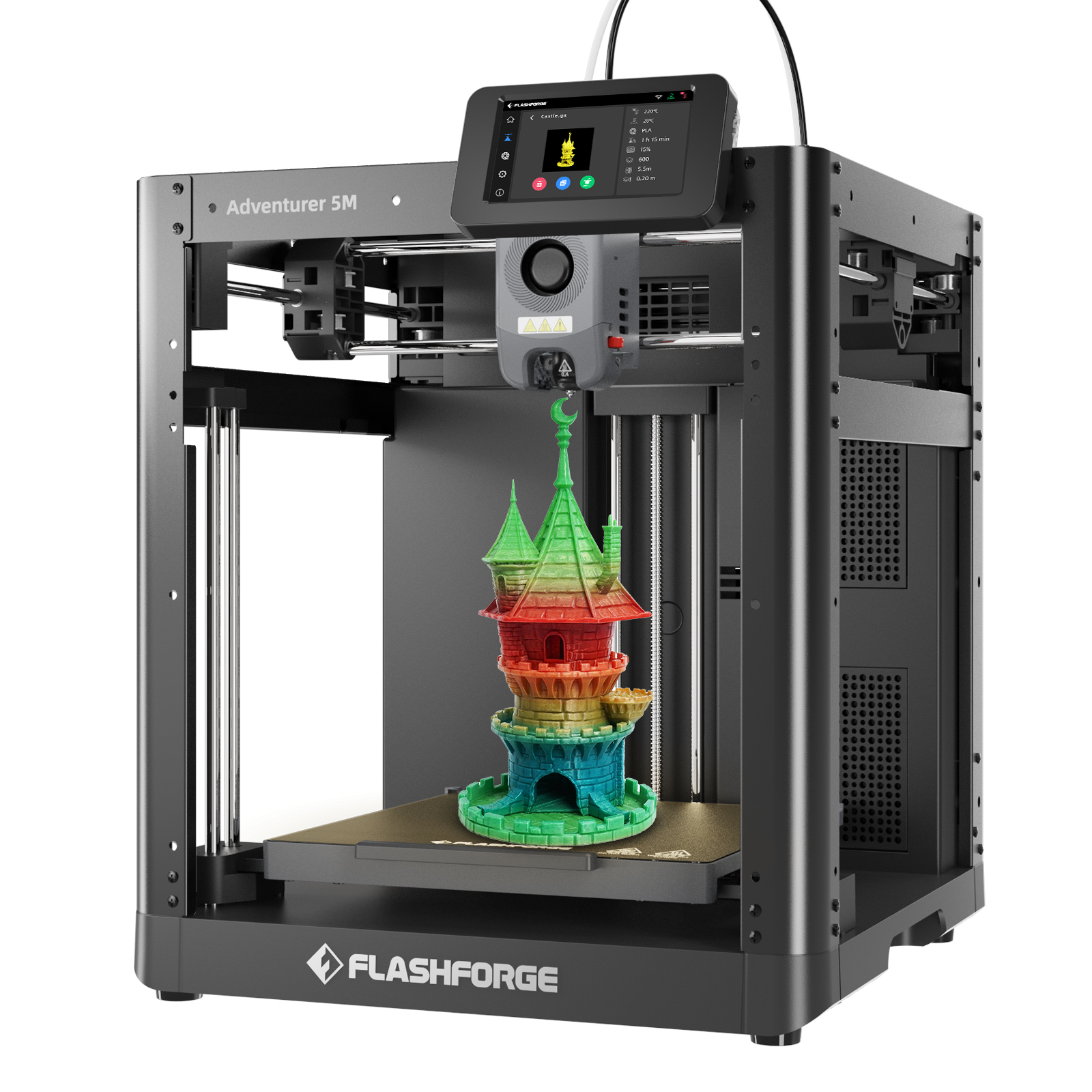

A cute net friend shared her 3D printed 3D printers. She used a Flashforge Adventurer 3 3D printer and 3D printed another Adventurer 3. You see the baby 3D printer is much smaller than the mother 3D printer, and the baby 3D printer is unable to do 3D printing like its mother. Just looks like its mother in structure, but not in functional features.

▲3D printed 3D printer: Baby Adventurer 3

Case 2: UNR 3D printed a bioprinter in summer 2022

A team from College of Science of University of Nevada, Reno once 3D printed a bioprinter. It was designed for a project we hosted at the 3D Printing Club’s UNR Summer 2022 Printer Build day event.

▲Bioprinter created by University of of Nevada, Reno

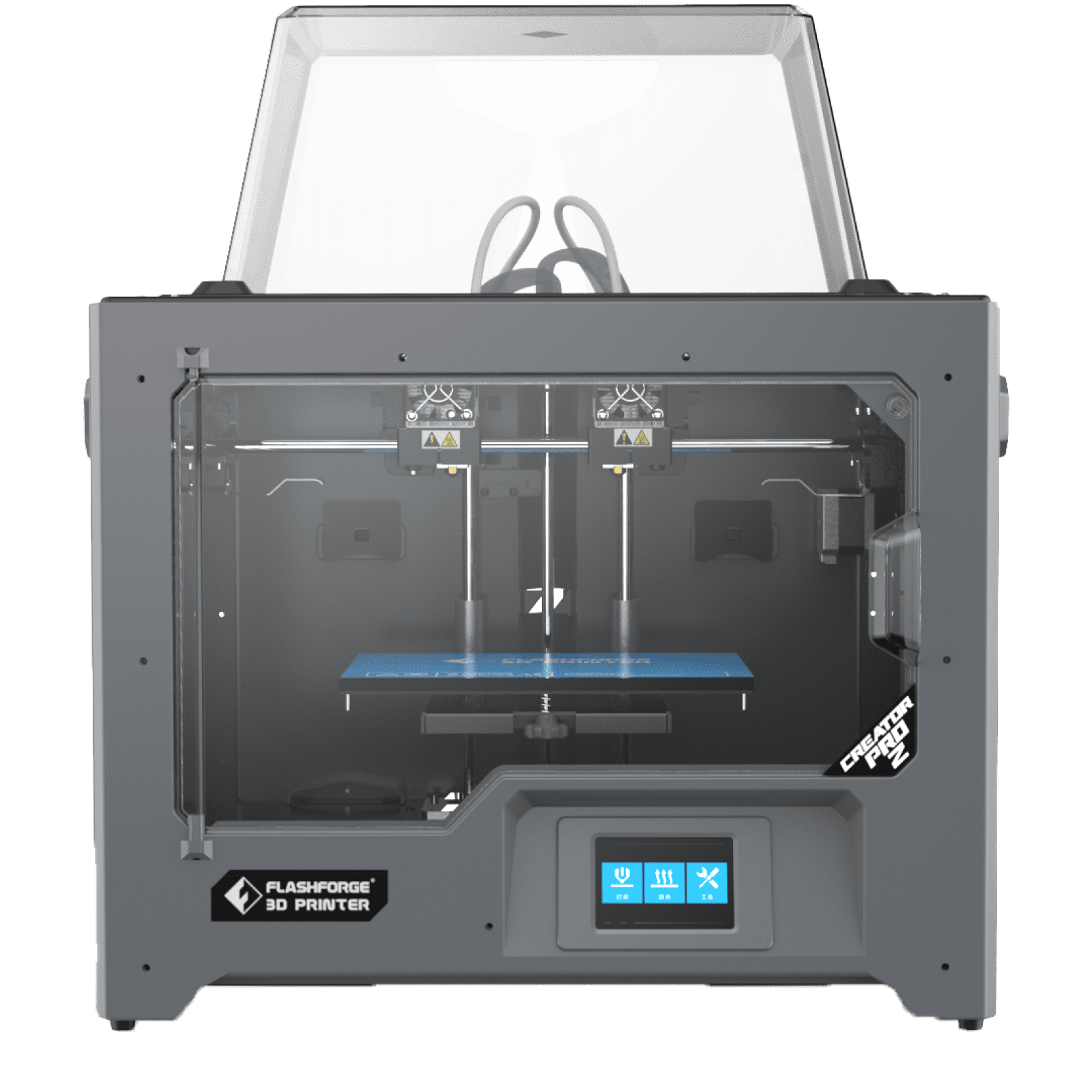

Under the lead of Lexa Baldwin, from Instructional Labs and Dean's Office of UNR, the team 3D printed a large number of the printable components with the Flashforge Creator 3 Pro 3D printer. They were successfully able to assemble the printer in one day and write an initial basic version of the firmware using Marlin. Most of the primary assembly and configuration was performed by students and researchers who were non-engineering majors, so as to help show that 3D printing and the building of printers is not something scary or overly complicated.

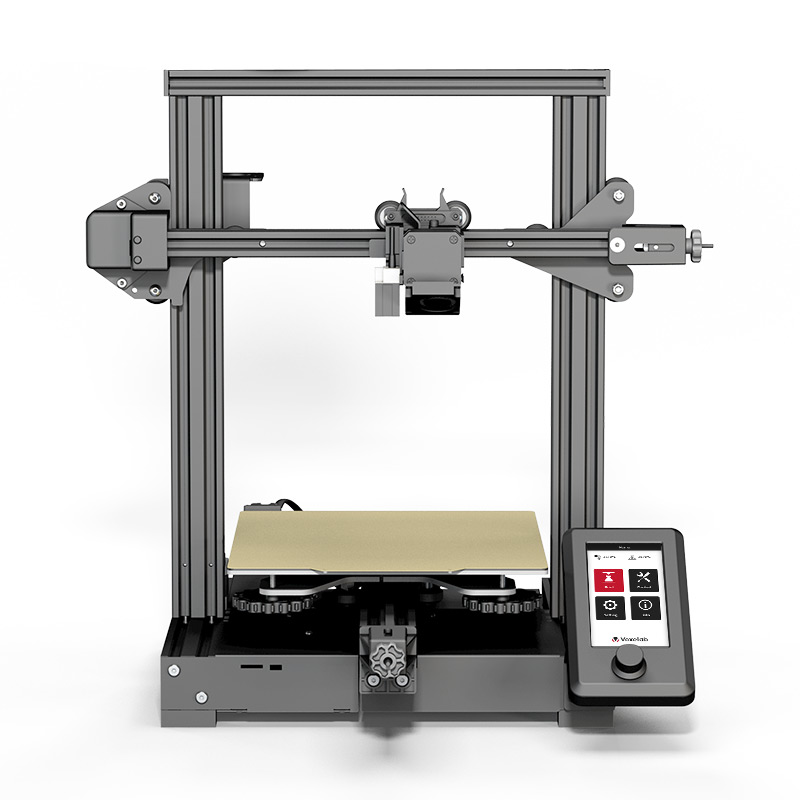

Case 3: Reprap 3D printer

RepRap is a type of 3D printer that is designed to be self-replicating. This means that many of the parts that make up the RepRap printer can be 3D printed by the printer itself. The plastic parts that are printed by RepRap include the frame, the motor mounts, the belt tensioners, and other structural components. By printing these parts, RepRap is able to reduce its reliance on traditional manufacturing methods and make the printer more accessible and affordable for users.

▲Self-replicating Reprap 3D printer

Case 4: Prusa 3D printer

Another practical example will be Josef Prusa's Prusa 3D printers. They have 3D printed parts in them. Plastic parts used on Prusa 3D printers are printed by the same very machines, holding on to the original idea of the RepRap project. Here all the parts in Orange colour are 3D printed parts for Prusa.

▲3D printed parts on Prusa

Is it difficult to assemble a 3D printer?

3D print 3D printers. When finishing 3D printing parts for a 3D printer, we start thinking about assembly. It is not difficult to make a 3D printer. As long as we are familiar with the internal structure of the 3D printer, we can make a 3D printer based on our purchased assemblies and 3D printed parts. The internal structure of the printer includes the body frame, mechanical shaft, control circuit and other parts. The frame of the machine body is the place where makes two 3D printers different. Different body frames have different working performances. Choosing a suitable body frame can better ensure the printing accuracy of the 3D printer. Following show some key steps on 3D printer assembling.

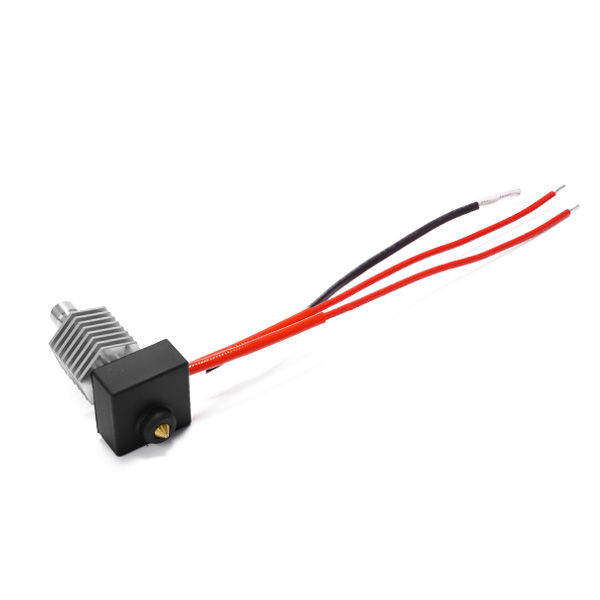

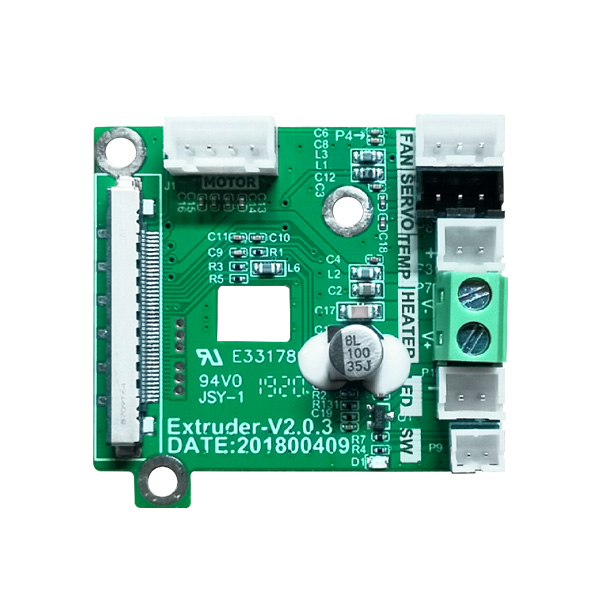

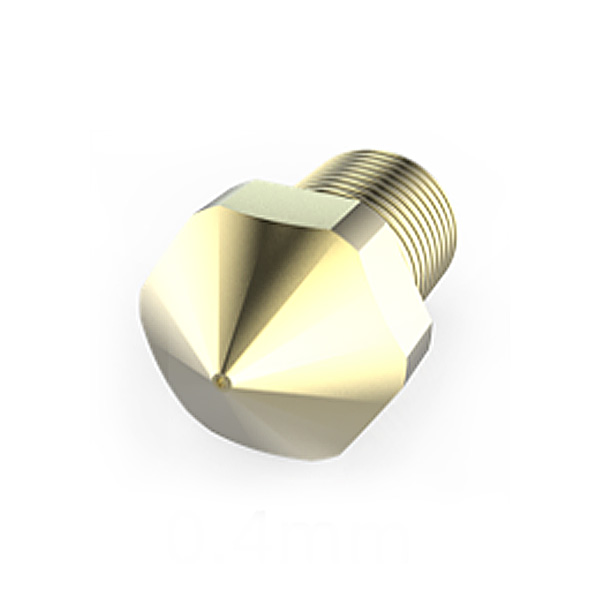

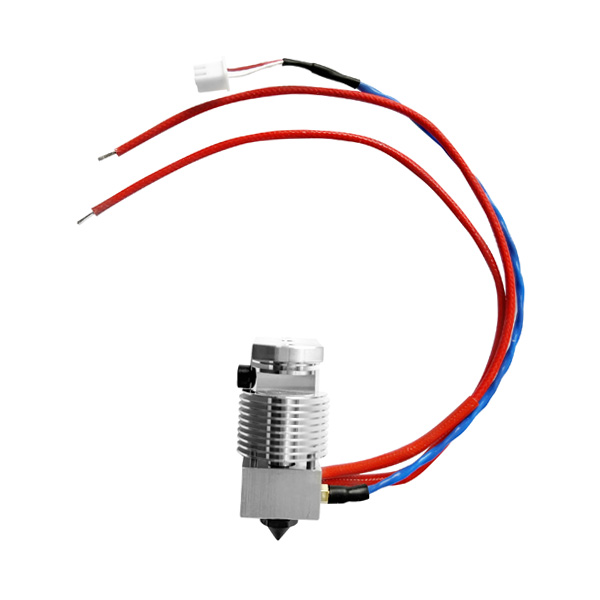

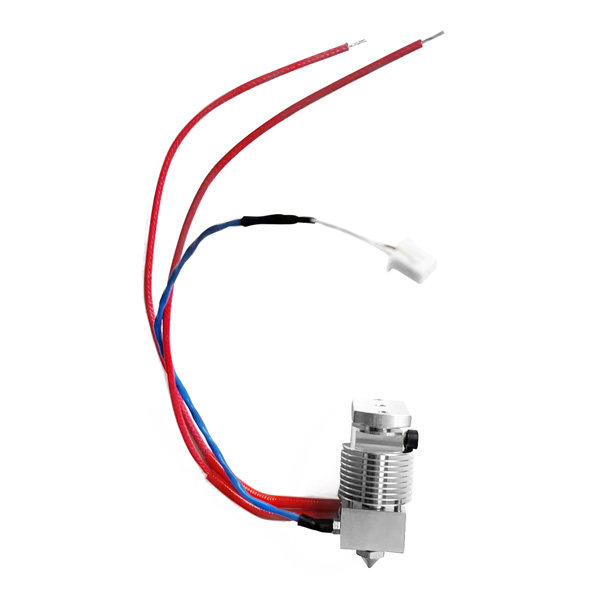

1. Assemble the extruder.

The first step of assembling the extruder is to connect the two fans with the nozzle of the 3D printer, which are connected with gears. Feeding the filament from the gear part of the 3D printer, and reserve enough space for the filament.

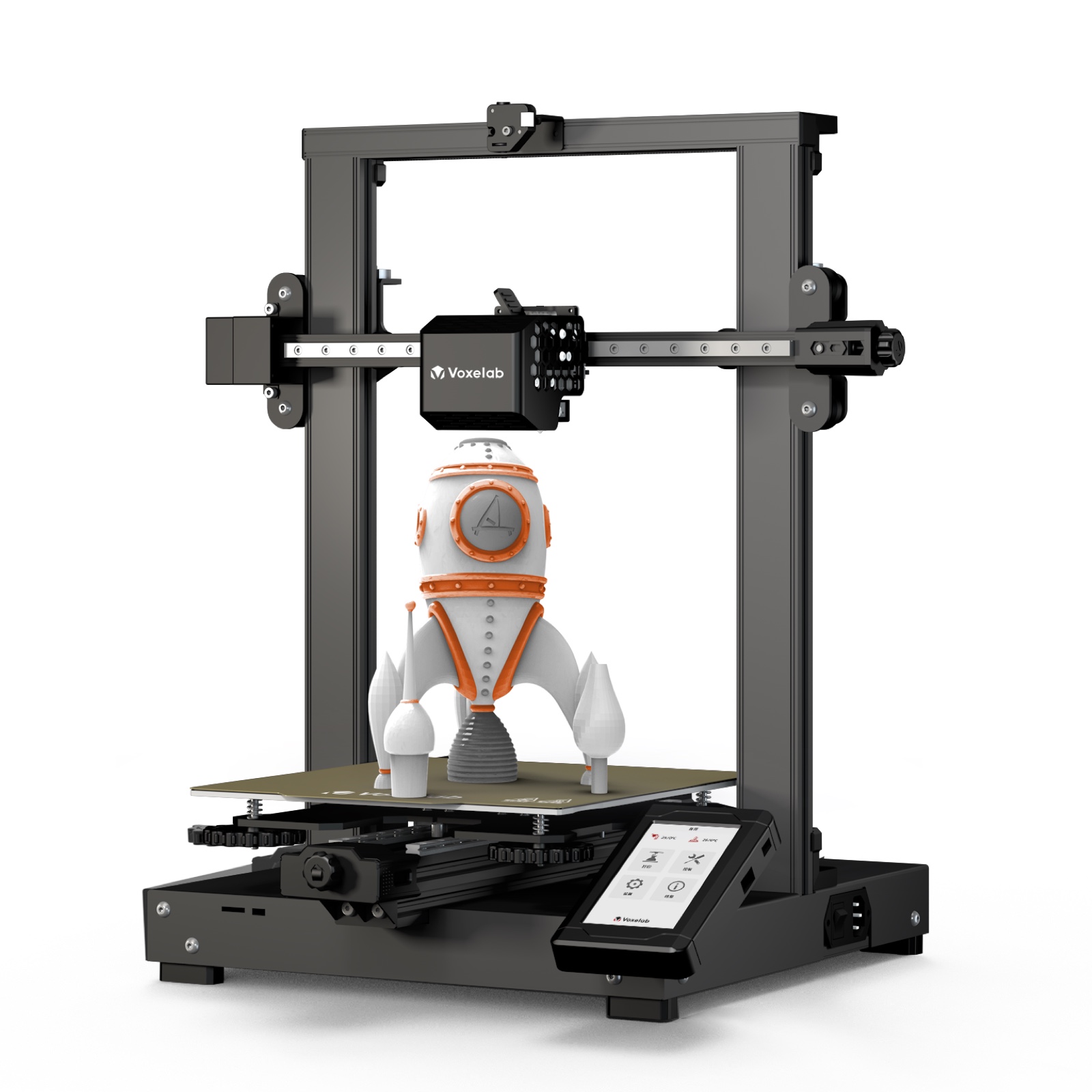

▲3D printer extruder assembly

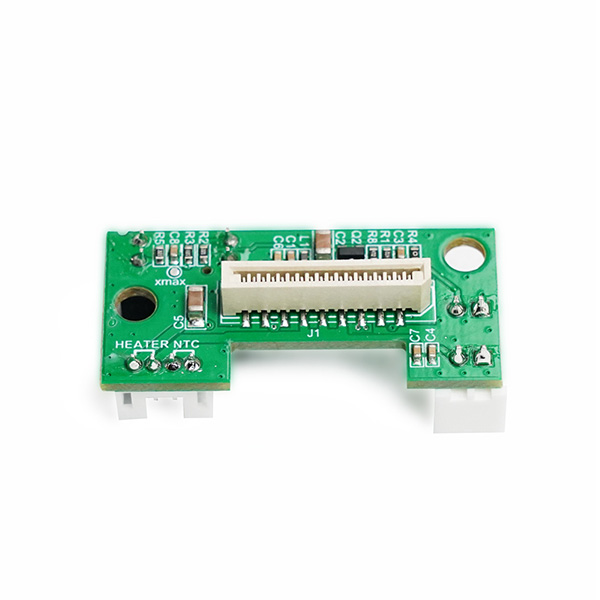

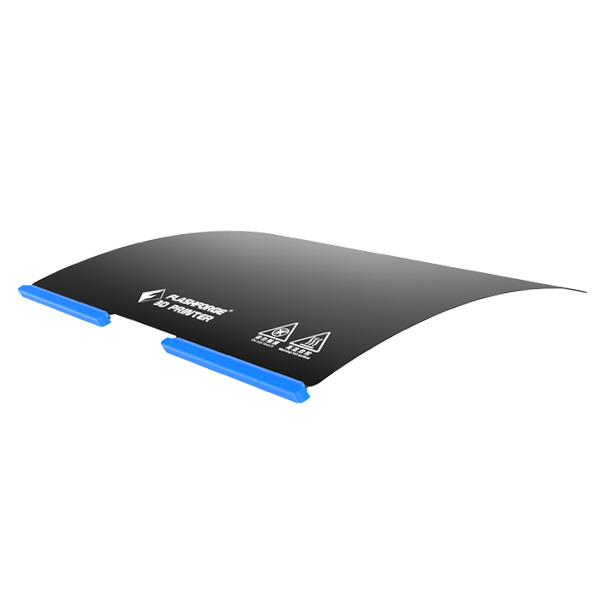

2. Installing 3D printer base

During the installation of the base, a base plate is required to assist in the construction. With screws, Acrylic board can be used to fix the power supply to the base. The main board part be fixed with rail structure..

3. Wire arrangement

To connect the black and red wires to the relay part of the main board, and then to build a power switch.

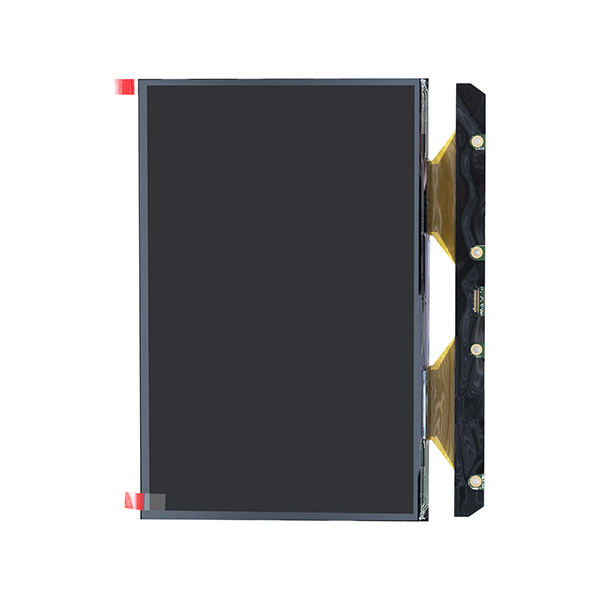

4. X axis, Y axis, Z axis part

The X-axis, Y-axis, and Z-axis parts need to be installed with sliding wheels to ensure that the nozzle can slide flexibly along the axes during the printing process.

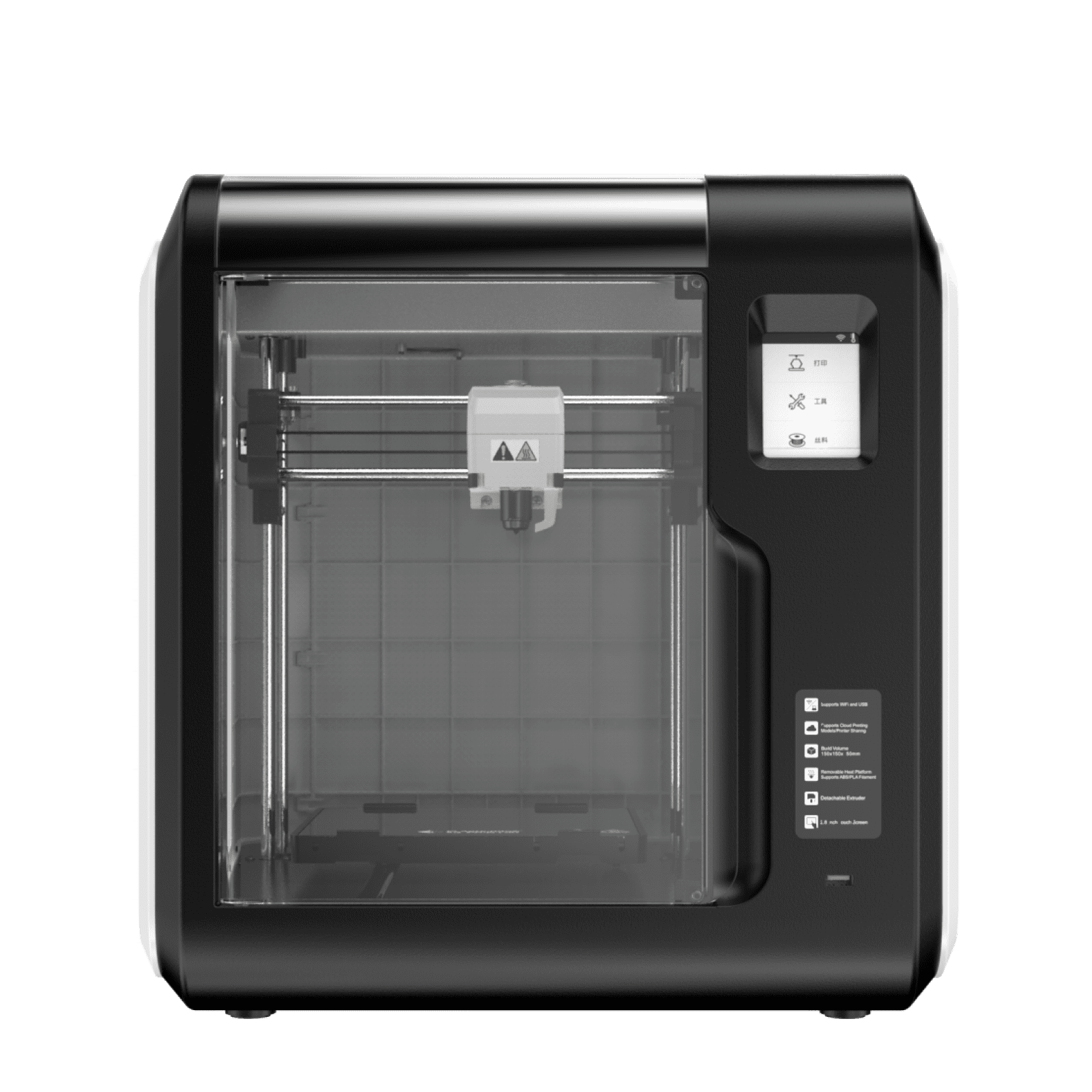

▲Assembling a 3D printer

5. Installing specific motors

The Z-axis part needs to add a synchronous wheel motor. Build a parallel structure to jointly promote the Z-axis movement. The position of the screw rod needs to be manually adjusted horizontally. Use the motor to drive the screw to swing and move up and down along the thread direction. The internal coupling part also needs to clamp the motor shaft and the screw rod to prevent the screw rod from falling off the shaft and causing damage to the motor.

6. Installation of tracks

A specific gear rack is needed, and the belt needs to be tightened to prevent loosening.

All in all

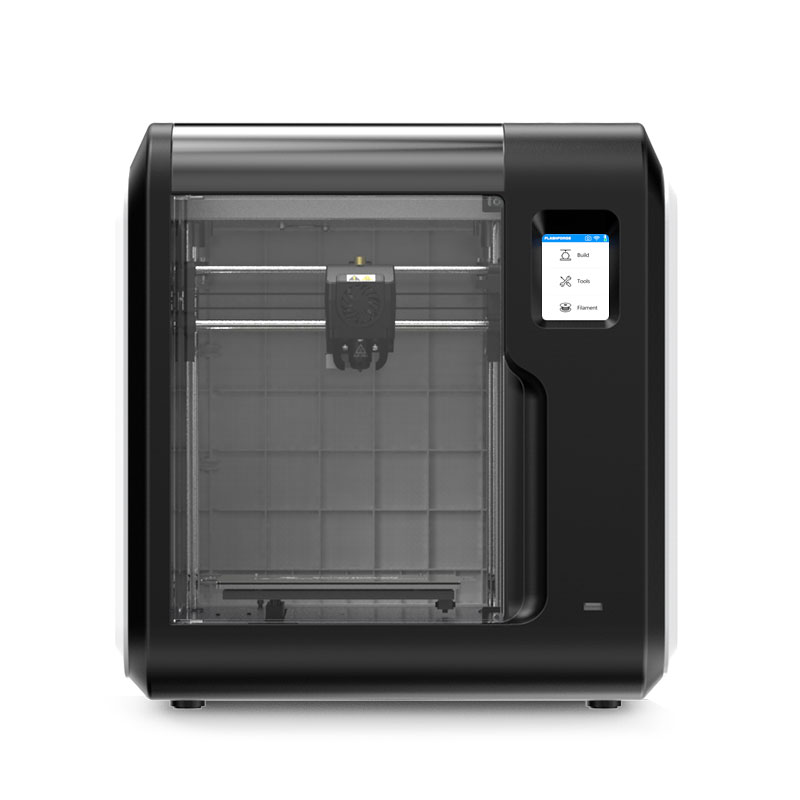

This article shows 4 real cases of 3D printed 3D printers and displays some key steps to assemble 3D printed parts together with those engineering and electronic parts. It is important to note that building a 3D printer from scratch can be a challenging and time-consuming process. It requires a good understanding of 3D printing technology and some mechanical skills. Therefore, it may not be the best option for beginners or those with limited experience. How about get a ready-made 3D printer directly on Flashforgeshop?

To learn more about Flashforge 3D printers, 3D printer prices, or to get help in deciding which 3D printer is right for you, welcome to visit Flashforgeshop. We offer best service in 3D printing field.