Do you face any quality issues with your 3D prints? Are you worried about 3D printer stringing or other imperfections in your 3D printing? Do you want to find its root causes and ways to tackle them? You’re in the right place, and this post is for you!

Stringing in 3D prints is made of thin strands of plastic that resemble cobwebs or strands of hair. This error distorts the quality of your 3D printing and doesn't give your products a finished look. Whether you’re a beginner or an experienced user, you may face complications if you do not know the causes of stringing in 3D printing and how to stop it.

Let’s dive in to explore what could be the root causes and, most importantly, how to stop stringing 3D printing.

What Could Be the Root Causes of Stringing in 3D Printing?

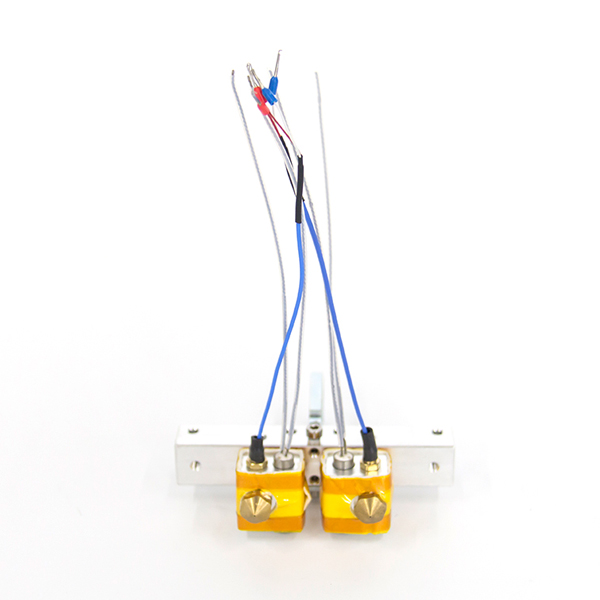

On default settings, many 3D printers, including FDM printers, can cause the nozzle to travel across an open space and to the next point. Then, it oozes molten plastic and sticks to the printed parts after solidifying. That is 3D printer stringing, which leaves your 3D prints looking like whiskers.

Now have a look at the causes of stringing in 3D printing.

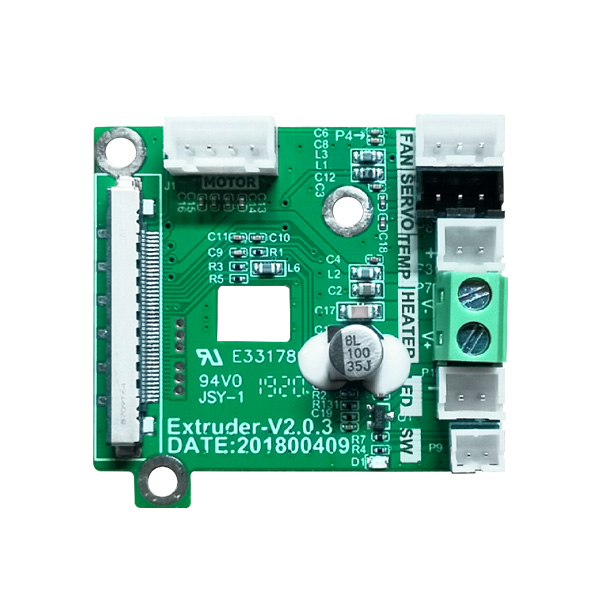

Extruder Temperature

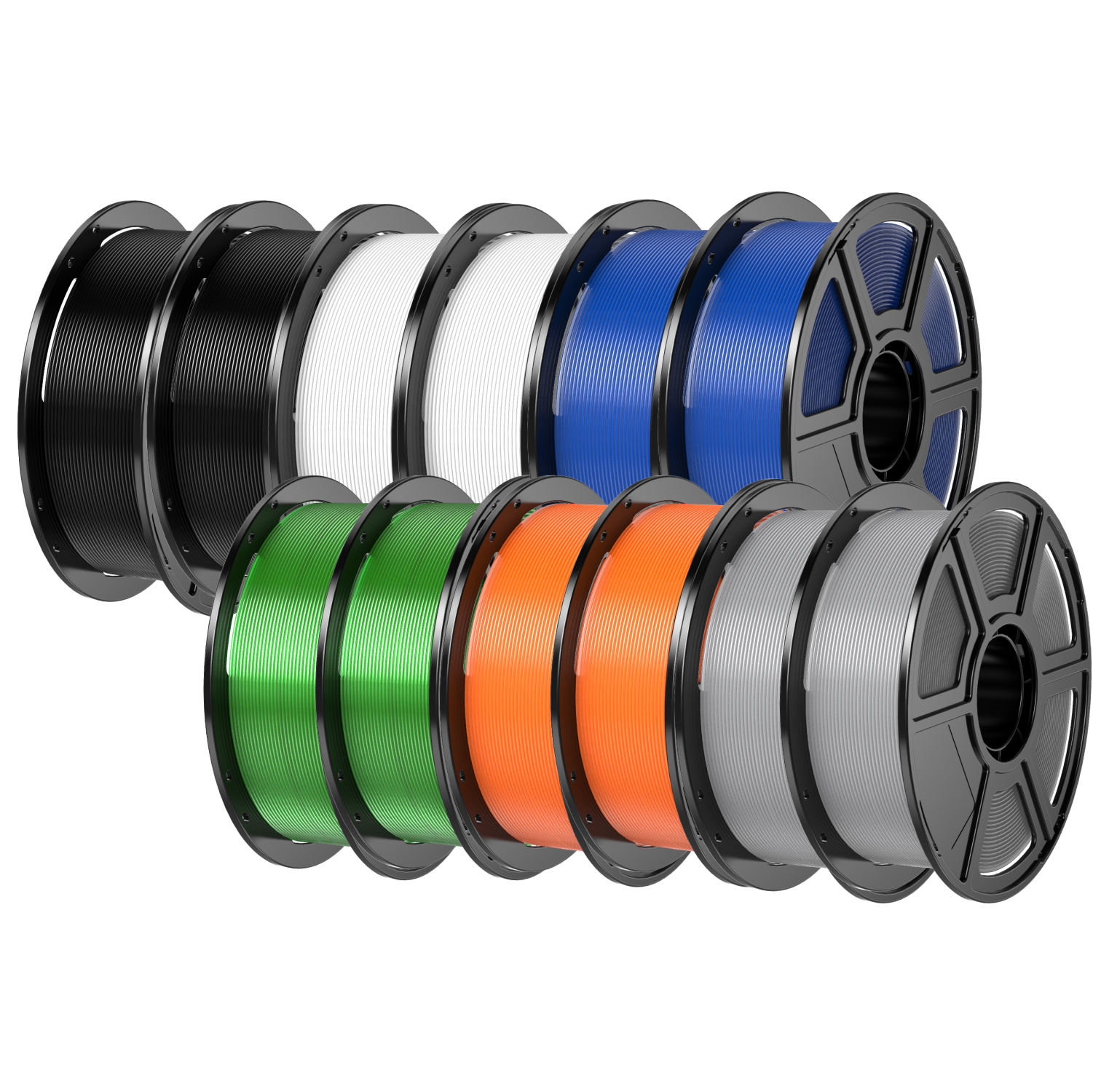

In any case, if the extruder temperature is too high, it may cause the 3D filament to melt unnecessarily and ooze out of the nozzle. That occurs with materials like nylon and ABS, which have a higher melting point.

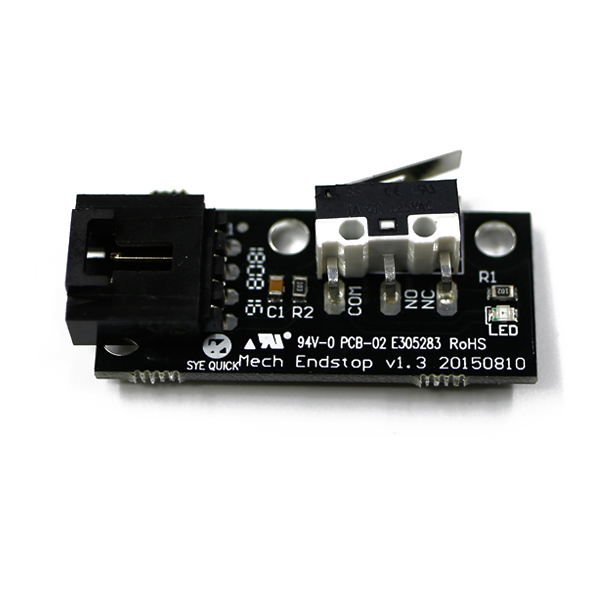

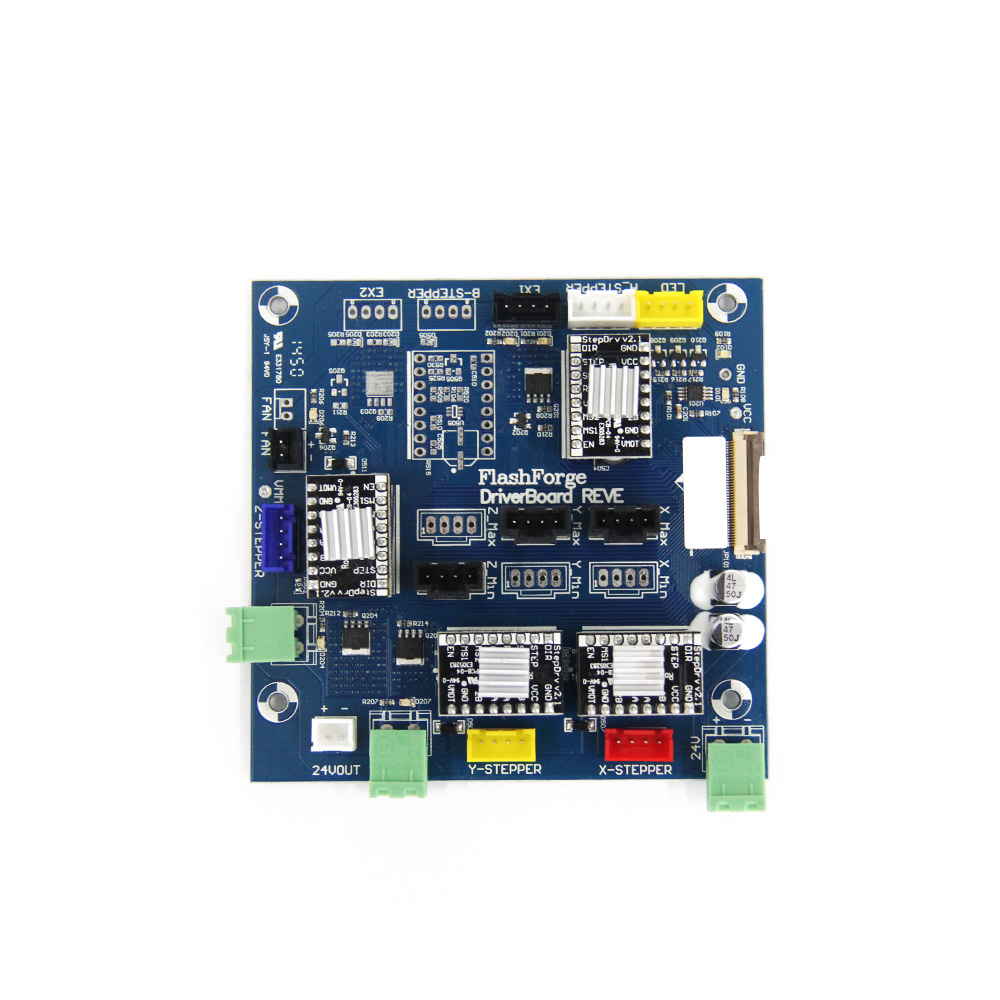

Retraction Settings

With reverted retraction settings, you may face 3D printer stringing. The purpose of retraction is to pull back into the extruder to prevent ooze. In some cases, when a retraction speed is set too slow, or the retraction distance is set too low, it can cause the 3D filament to pursue oozing out of the nozzle and form strings.

Print Speed

Another cause of 3D printer stringing is higher print speeds. With higher print speeds, the 3D filaments can be extruded again because they have less time to solidify.

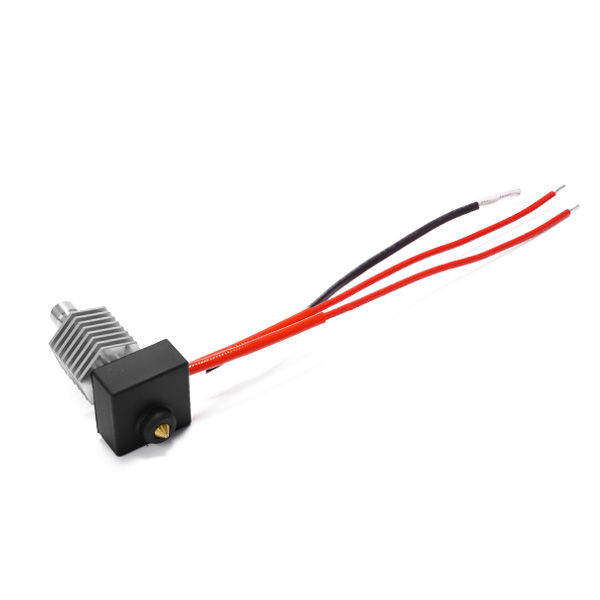

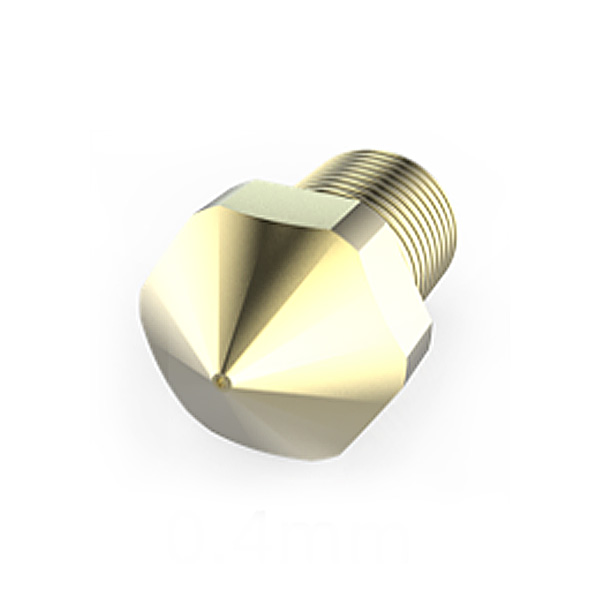

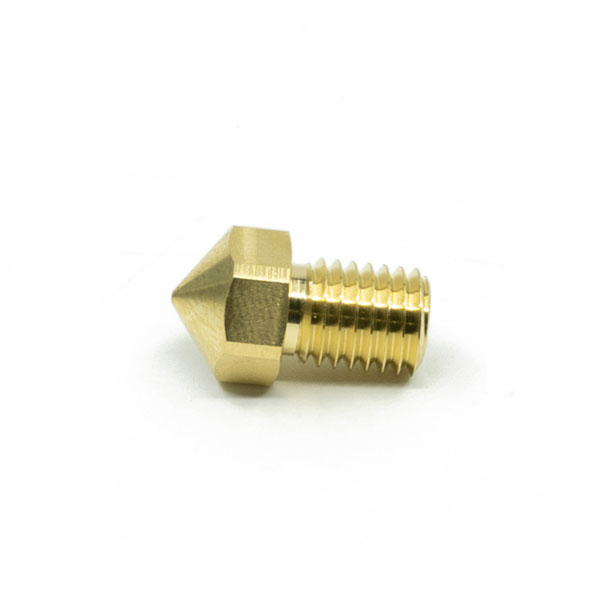

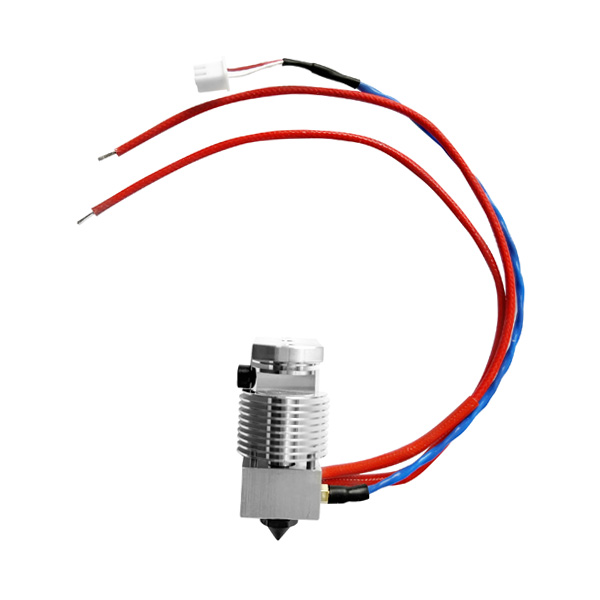

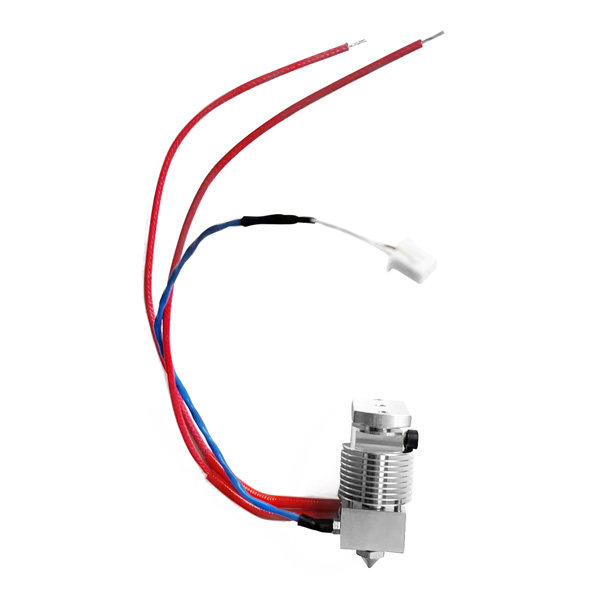

Nozzle Size

A nozzle with a large diameter can also cause stringing. In this situation, it allows for more filament to be extruded at once, and after solidifying, it forms strings that distort the quality of your 3D prints.

Cooling

In 3D printers, fans are near the hot end for cooling purposes. These fans blow cold air under the nozzle to cool off freshly-extruded plastic. When your cooling fans are not working well, your materials will cause more stringing.

Now you have a proper understanding of the causes of stringing in 3D printing. Let’s explore how you can secure your 3D printer to not form strings with safe search settings.

Effective Ways to Fix 3D Printer Stringing

Want to consider how to fix this issue and keep your 3D prints looking their best? Let’s explore it.

Adjusting the 3D Printer’s Temperature

When your 3D filament is too hot and starts to melt before it’s supposed to, it can leave strings behind. At this time, you try to decrease the temperature of the hot end by a few degrees.

Besides, if the 3D filament is too cold, you can increase the temperature of the hot end. With cooled 3D filaments, it’s tough to extrude, and it can clog the nozzle. Consequently, you’ll receive poor-quality prints.

With safe search settings, you can optimize your 3D printer's temperature, which may vary according to the specific 3D filament you are using. Likewise, if you face any issues, such as with PLA stringing, you can adjust the temperature between 180-220 degrees Celsius.

Optimize your Retraction Speed and Distance

Retraction Distance

In setting the retraction distance, ensure not to pull back too much 3D filament. This way, it can leave unwanted filaments on your 3D-printed objects. Contrarily, when the filament does not retract far enough. Then it will again result in stringing. The best retraction distance is between 0.5-1mm. But it can vary depending on the filament and the details of your print.

Retraction Speed

The appropriate retraction speed is between 20-40mm/s is a good starting point. Moreover, it can vary depending on your printer and the filament.

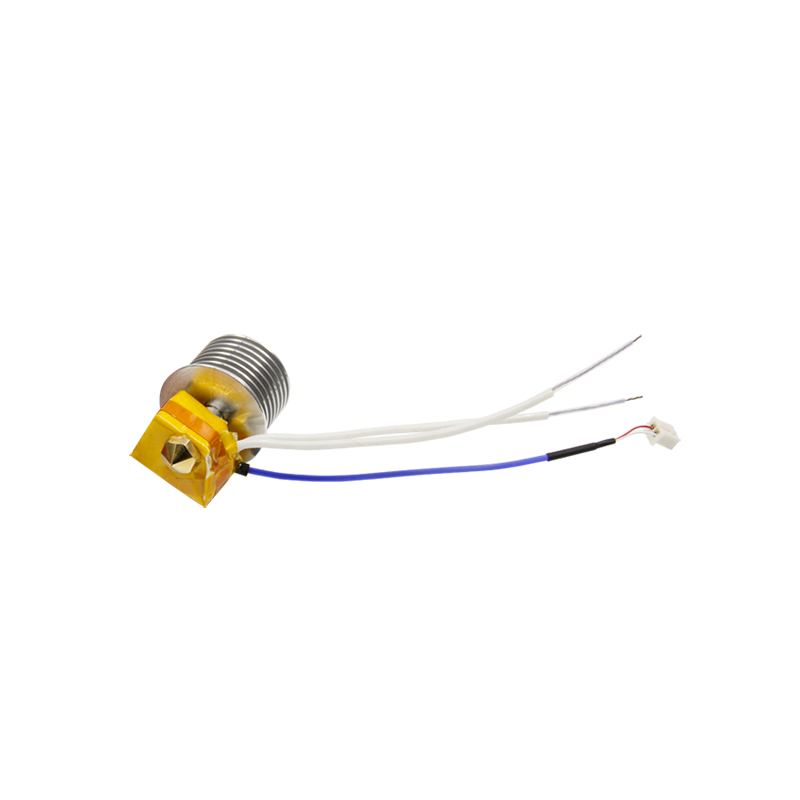

Cleaning Your 3D Printer’s Nozzle

When using a printer for a long time, particularly with a single type of 3D filament like PETG, it can leave a thin residue layer in the nozzle. This residue layer can cause 3D printer stringing. To avoid this, ensure your nozzle is cleaned well before operating a 3D printer.

Final Thought

Stringing in 3D prints is the focus of concern because it affects the quality of your 3D printed products. If you want to achieve high-quality 3D-printed products consistently, then you must keep these causes in mind and try to overcome them before operating a 3D printer.

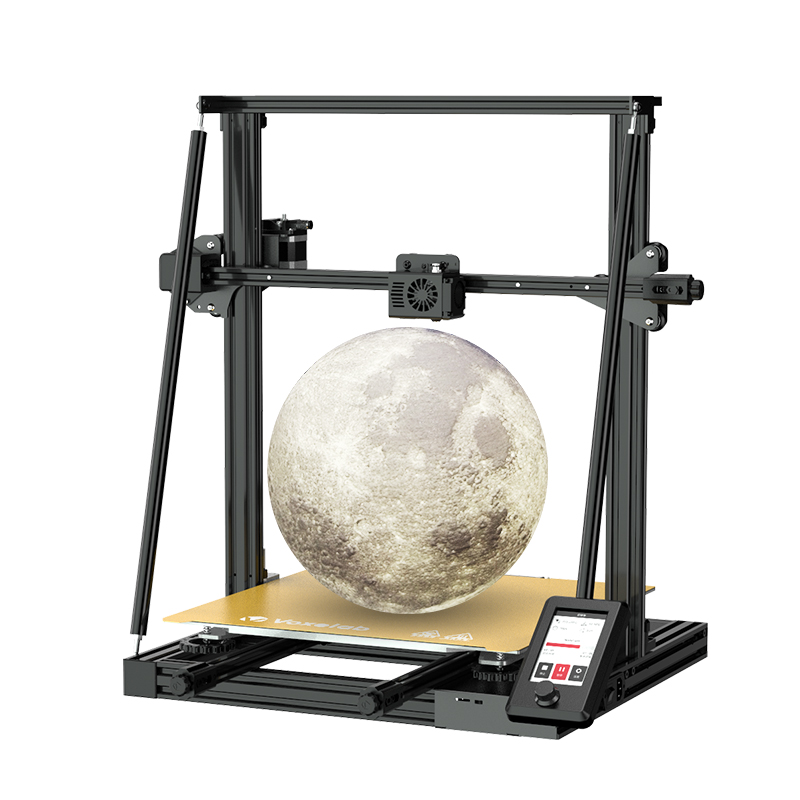

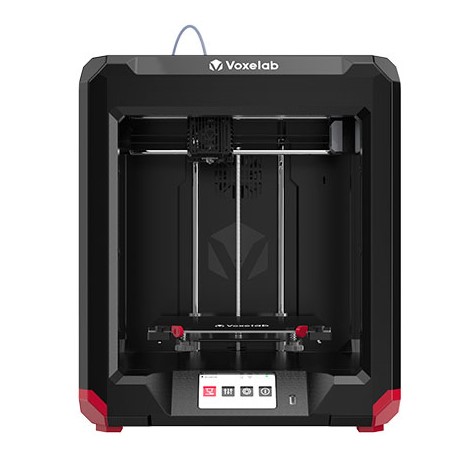

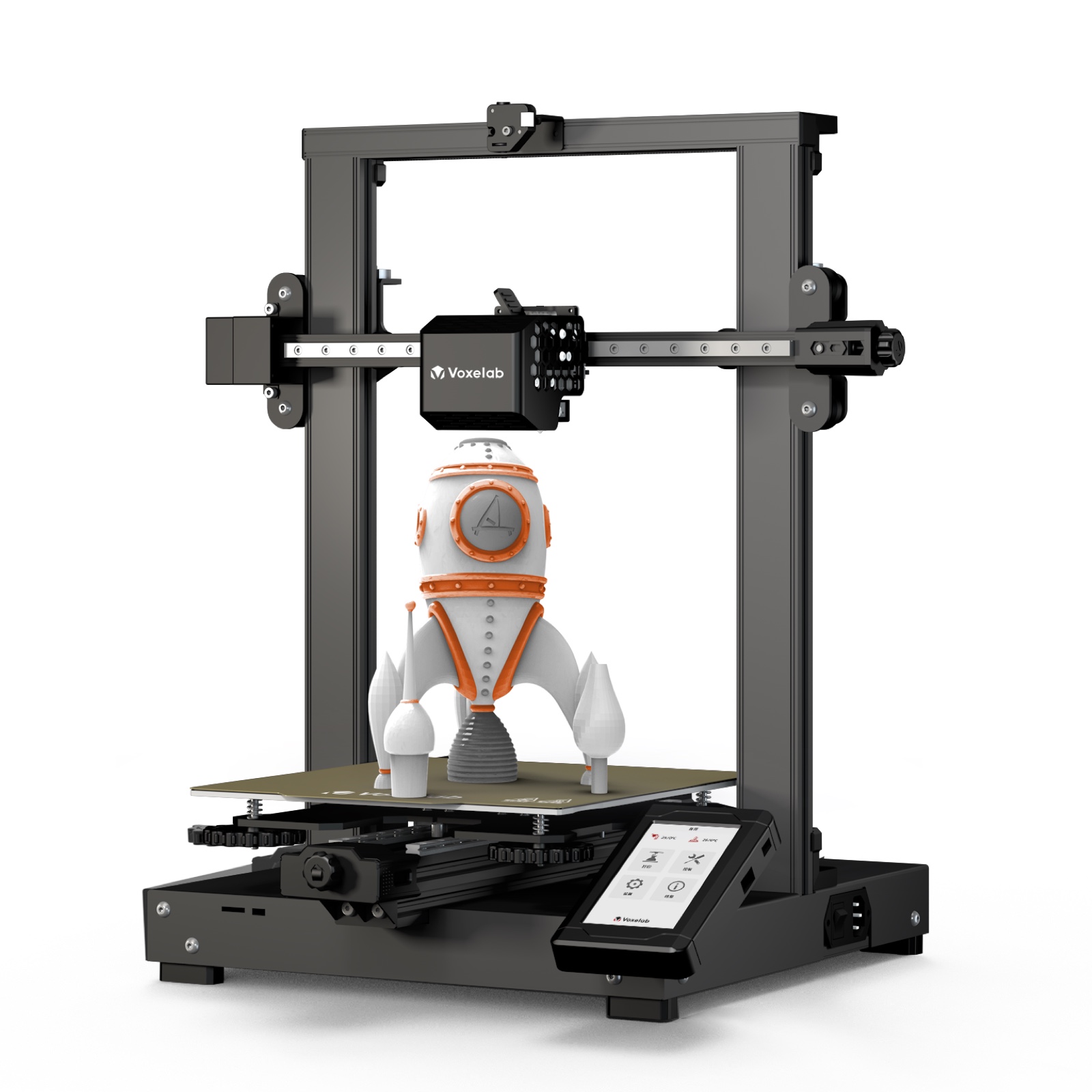

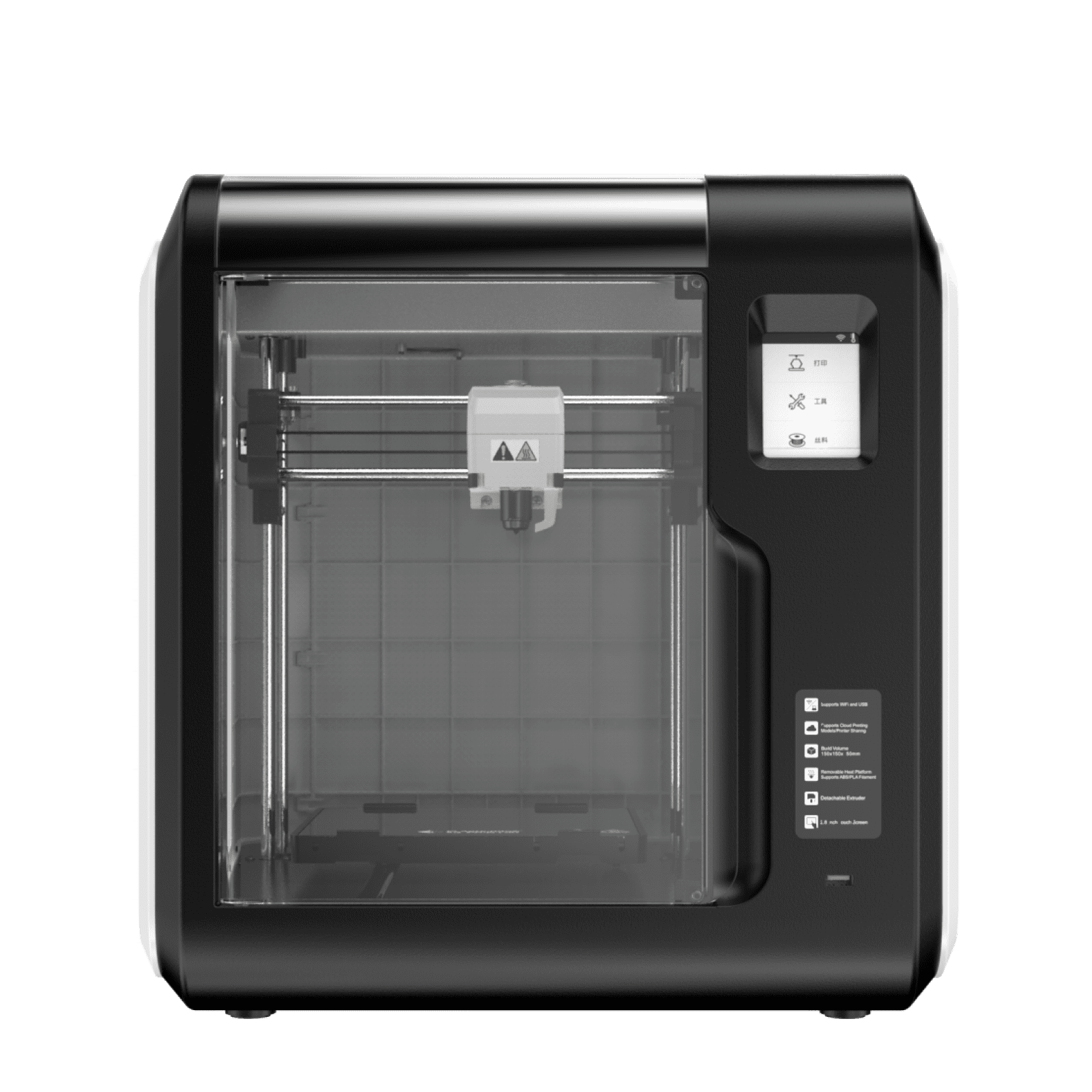

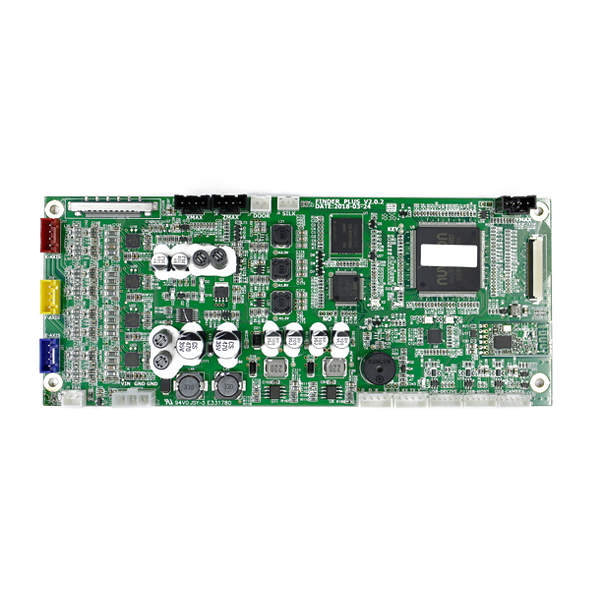

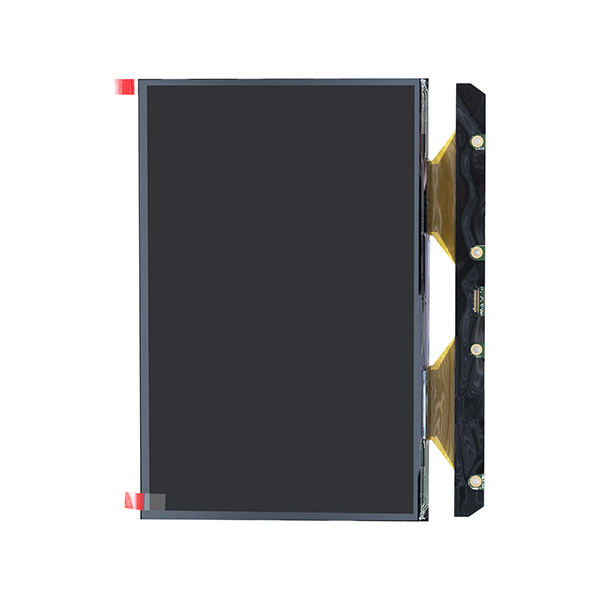

Besides, if you use a high-quality 3D printer, you won't need to consider these causes or effective ways to fix them. For high-quality 3D printers, you can visit Flashforge shop.