Imagine you have been working on a 3D printing project for hours, and you finally have the perfect design. You hit print, but something goes wrong, and your creation doesn't turn out as expected. You may have forgotten one crucial element in the printing process: temperature. PLA temperature plays a critical role in the quality and outcome of your 3D prints. In this article, we'll dive deeper into PLA filament and its properties, so you can understand how temperature affects it and achieve the best results possible. Get ready to become a 3D printing temperature pro!

PLA Filament Temperature Settings

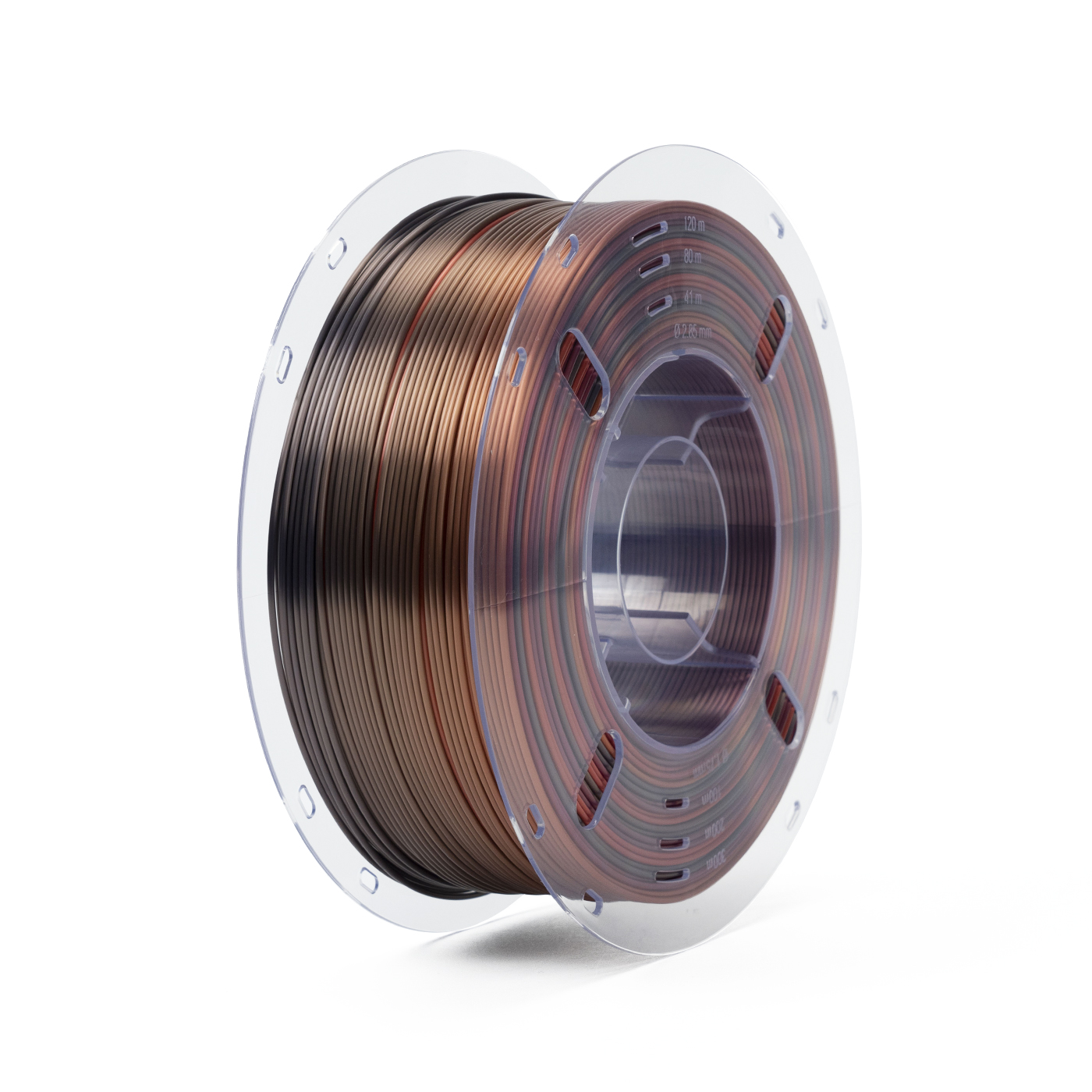

When it comes to PLA filament temperature settings, it's important to pay attention to the recommended temperature range for the specific brand of filament being used.

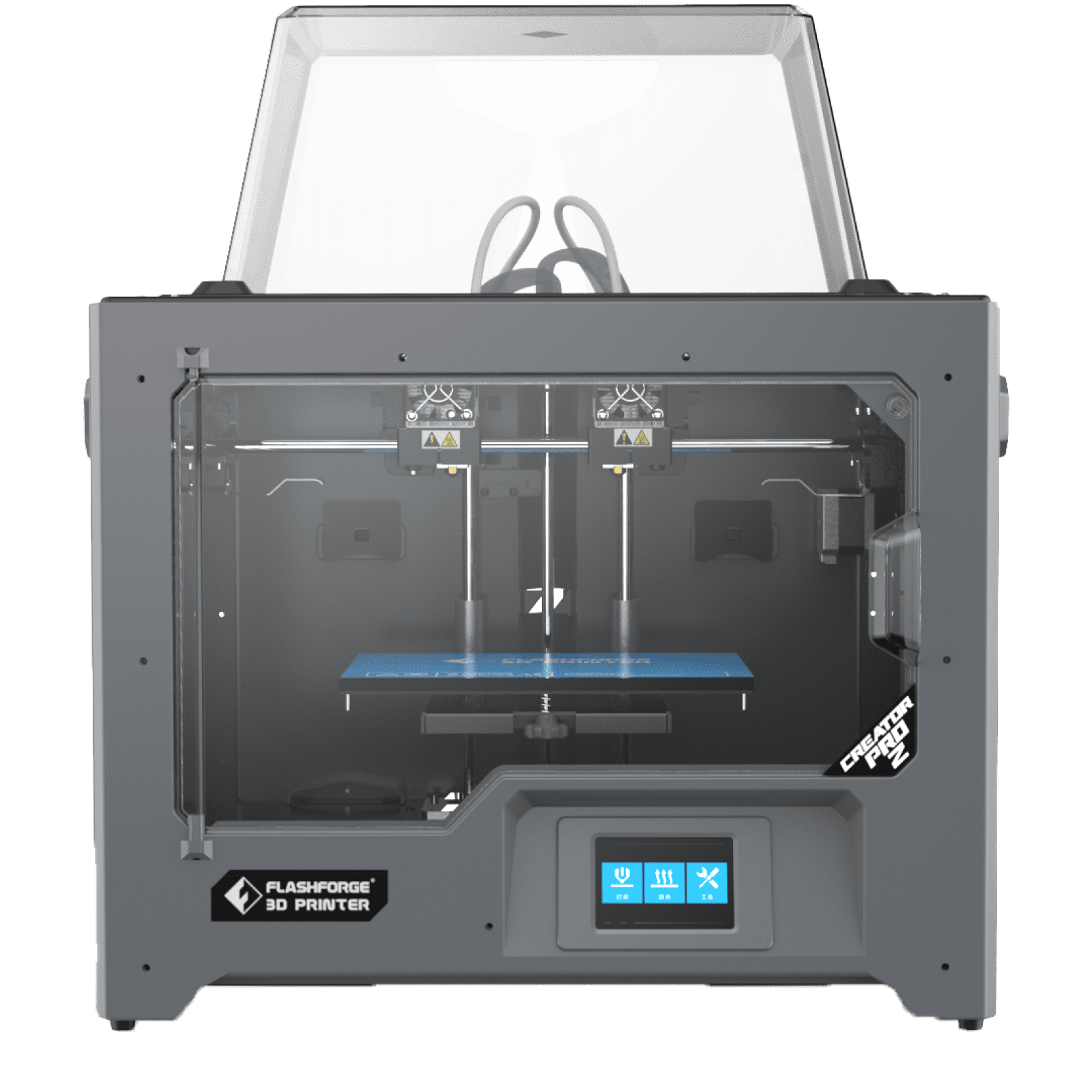

For example, Flashforge PLA filament has a recommended pla melt temp range of 190-220°C. However, it's also important to consider other factors that can affect temperature settings, such as print speed, layer height, and ambient temperature.

The relationship between temperature and print quality is also crucial to understand, as a temperature that is too low can result in poor adhesion and a rough surface finish, while a temperature that is too high can cause stringing and other issues.

By carefully adjusting temperature settings and taking other factors into account, you can achieve high-quality prints with PLA filaments.

Adjusting PLA Temperature for Different Printing Needs

When adjusting the PLA temperature for 3D printing, it is important to consider the specific details of your project.

For example, when printing highly detailed models with intricate features, a lower temperature setting may be required to achieve clean, crisp lines and prevent over-extrusion. On the other hand, for larger, more structural prints that require greater strength and durability, a higher temperature setting can help to achieve a stronger bond between layers.

For instance, if you are using Flashforge PLA filament to print a small, delicate figurine, the PLA best temperature setting of 190-200°C may be appropriate to ensure a smooth finish and maintain fine details.

On the other hand, if you are printing a larger object such as a vase or a phone case, a temperature range of 210-220°C may be more suitable to create a stronger, sturdier print.

Additionally, it is important to adjust temperature settings based on the desired layer height and print speed.

For example, when printing at a high speed with a larger layer height, a higher temperature setting may be necessary to ensure proper adhesion between layers and prevent warping or delamination. Conversely, when printing at a slower speed with a smaller layer height, a lower temperature setting may be sufficient to achieve the desired level of detail and precision.

Alexander Miliacic, Printed at 220 degrees with high extrusion temperature which resulted in deformed ship design, as he set up the extrusion to 92 degrees and temperature 210 degrees, the results were more than perfect.

Testing PLA Temperature Settings

Calibrating your 3D printer is crucial for achieving accurate and consistent results. This is particularly important when it comes to temperature settings for PLA filament. Inaccurate temperature settings can result in poor print quality, warping, or even damage to the printer.

How to perform a temperature tower test?

One effective way to test and fine-tune your PLA temperature settings is by performing a temperature tower test. This involves printing a single model with varying temperature settings at different levels, typically in increments of 5-10°C. The model will have several sections, each printed at a different temperature. Once complete, you can analyze the results to determine the optimal temperature for your specific PLA filament.

After printing the temperature tower, carefully examine each section for any signs of over or under extrusion, stringing, or other defects. You can use these observations to determine the temperature range that produces the best results. Once you have identified the ideal temperature range, adjust your printer settings accordingly and perform additional test prints to confirm the accuracy of your settings.

For example, if you are using Flashforge PLA filament, you may find that the best temperature range for your printer is between 200-210°C. However, this can vary depending on factors such as the color and quality of the filament, the ambient temperature of the printing environment, and the specific characteristics of your 3D printer. Testing and calibration are key to achieving optimal PLA temperature settings for your unique printing needs.

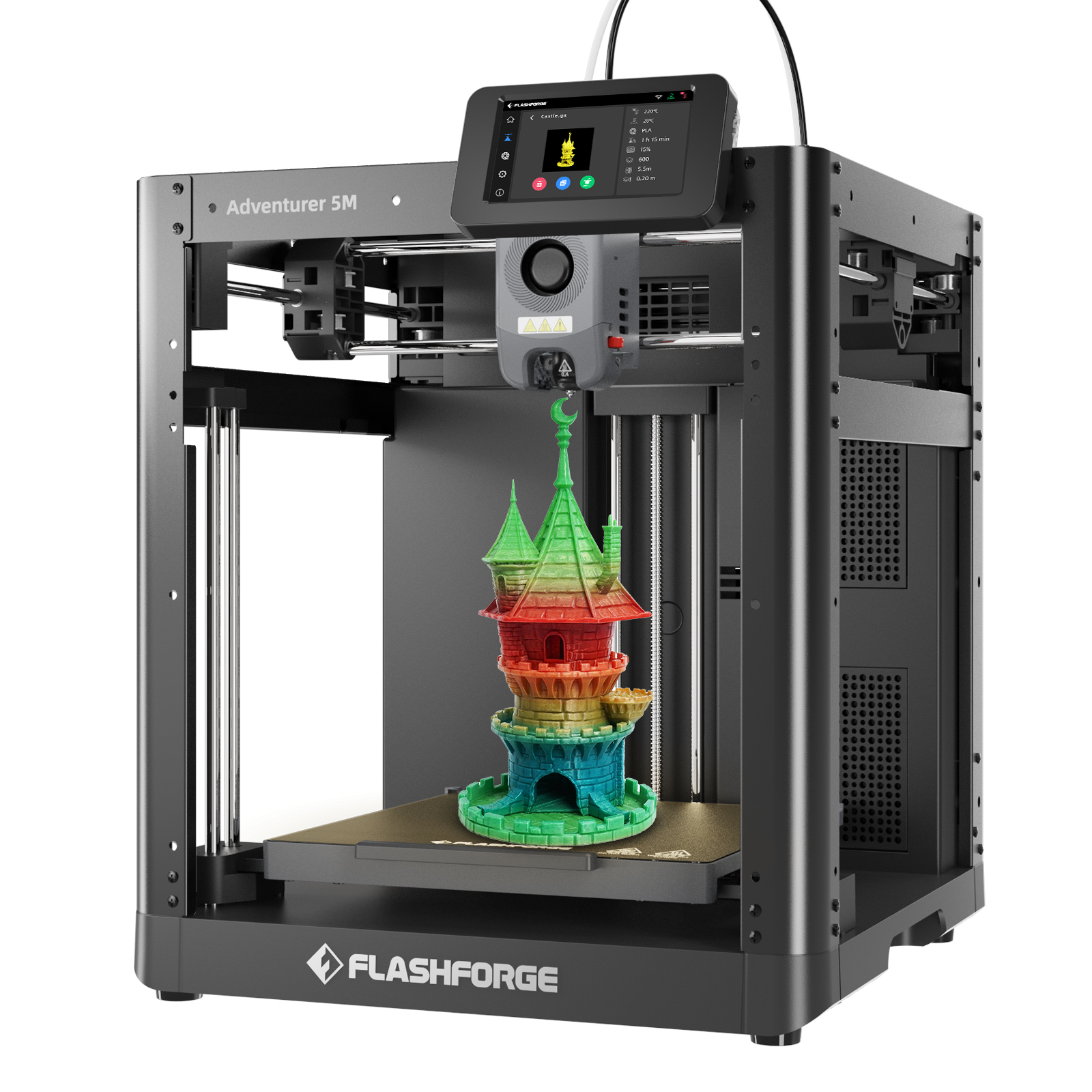

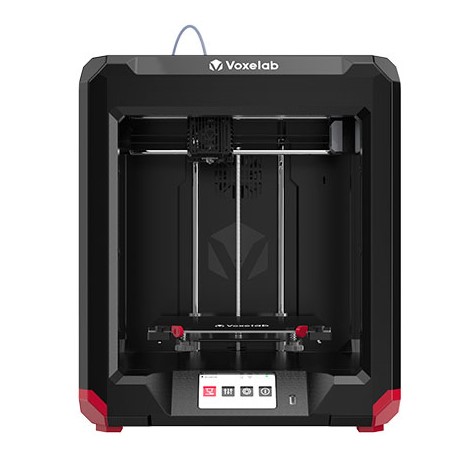

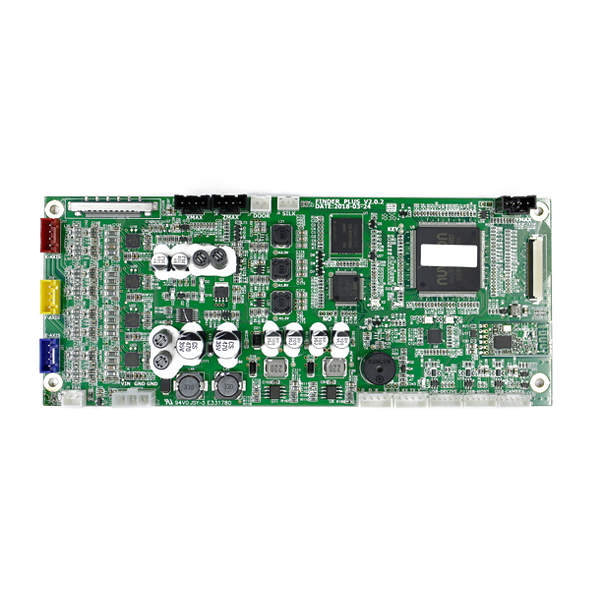

Steffan Aas, a 3d Printing Enthusiast used Adventurer 4 and FLashforge PLA filament to experiment with different temperatures and avoid stringing. He used the same nozzle but at different temperatures. He kept the door open, and made the other settings even, that finally gave him optimum results at 180 degrees.

Pro-Tips for Achieving Optimal PLA Temperature

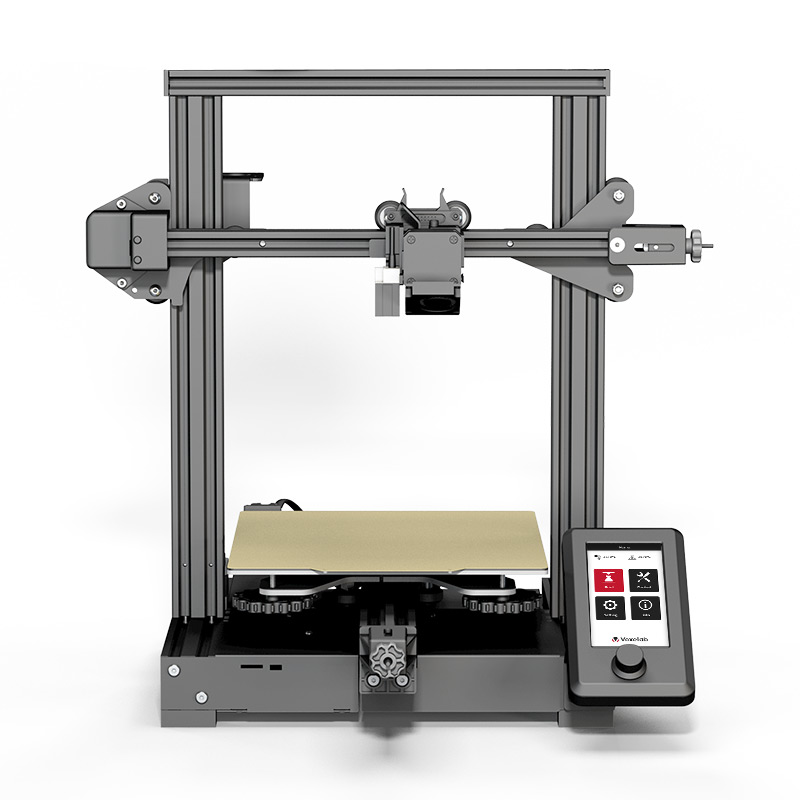

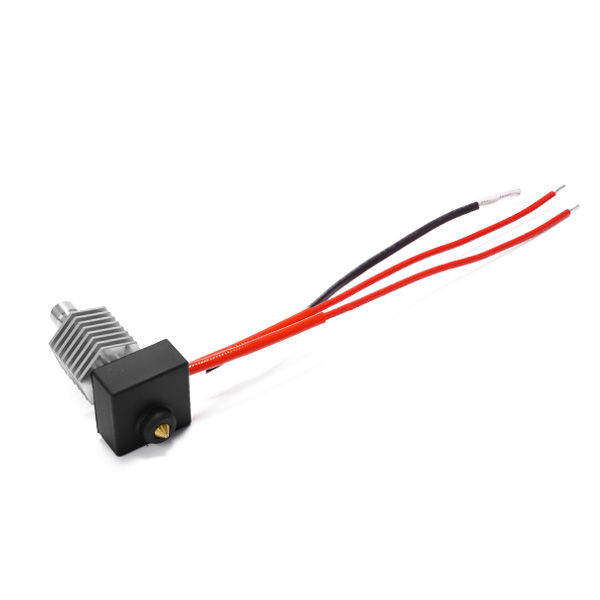

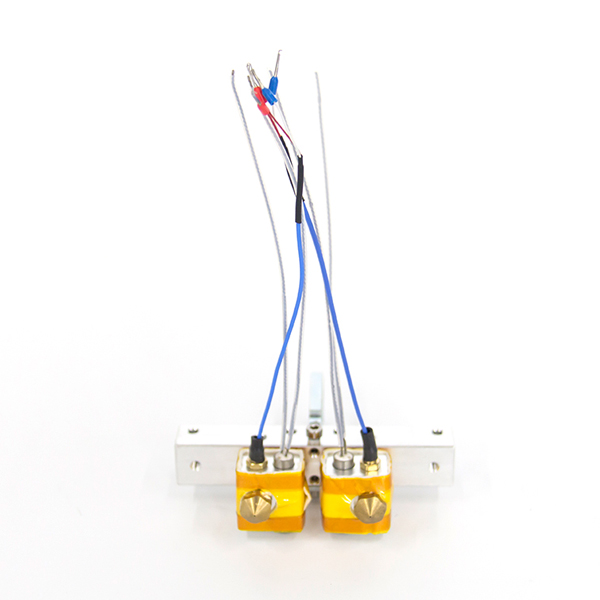

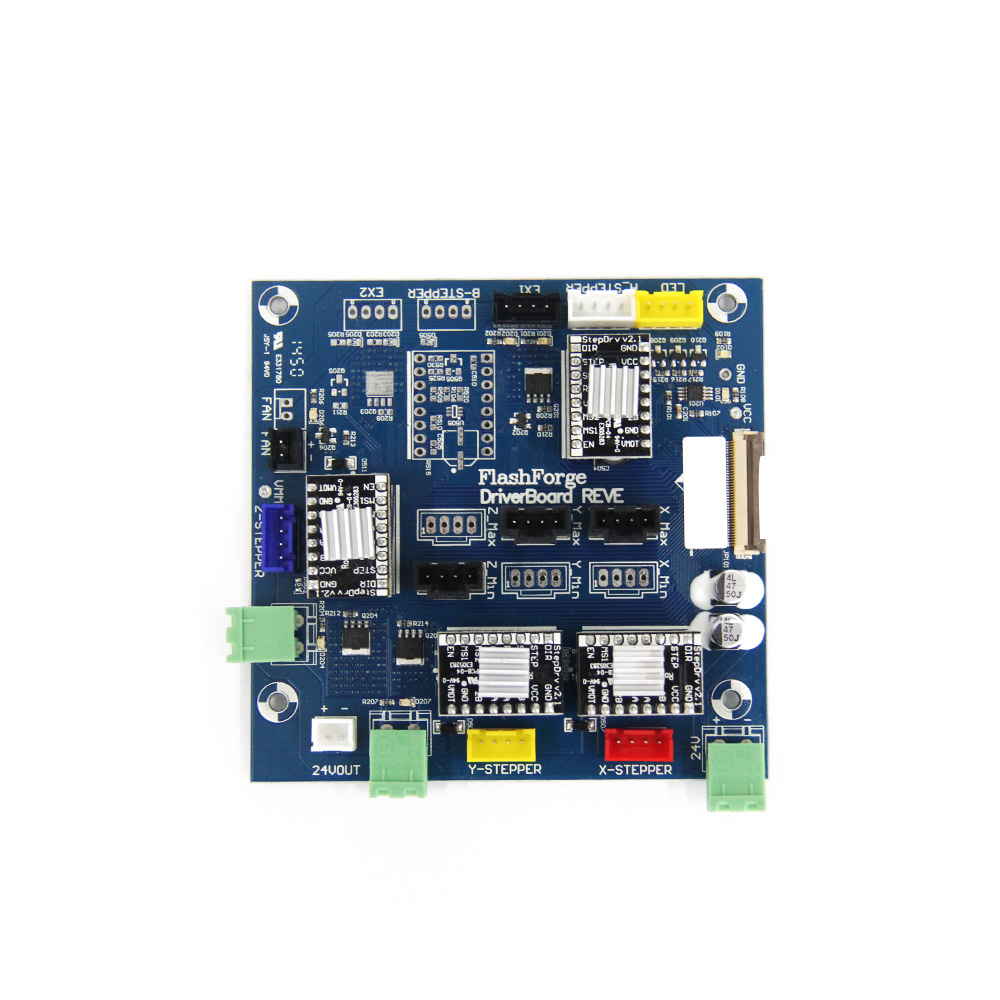

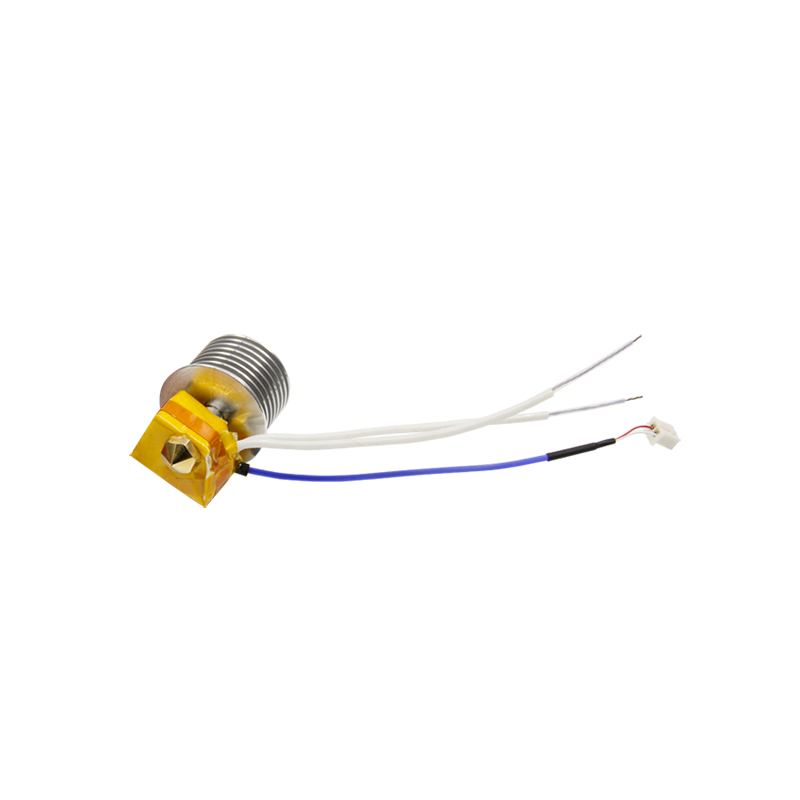

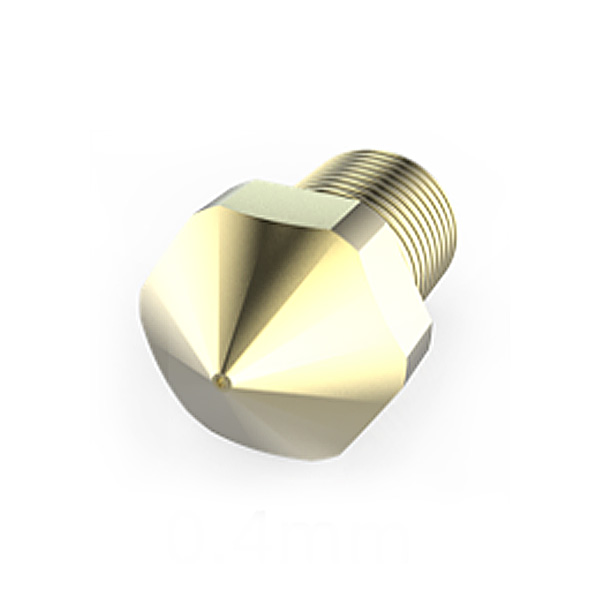

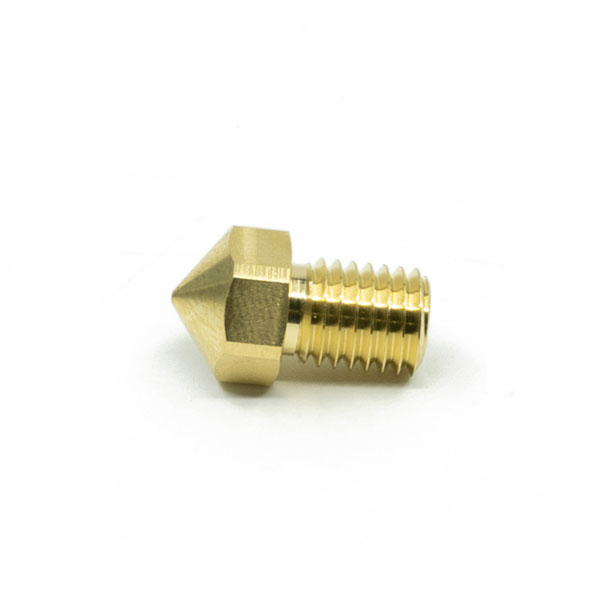

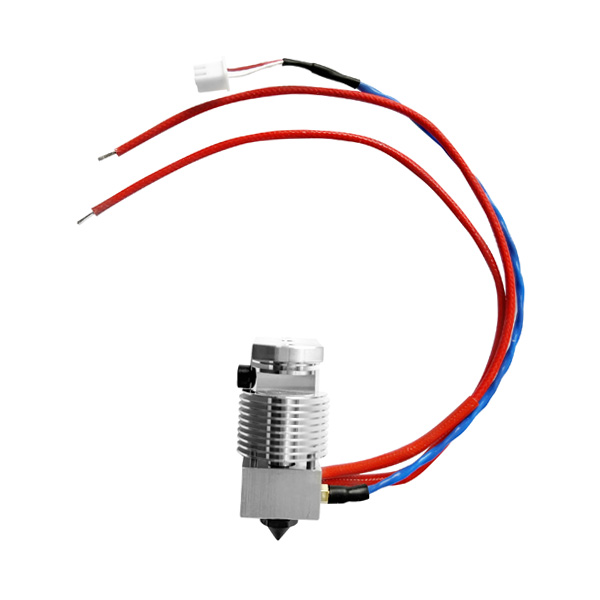

Choosing the Right Nozzle Size: The nozzle size used for printing with PLA can greatly affect the temperature settings. A smaller nozzle size will require higher temperatures to extrude the filament properly, while a larger nozzle size will require lower temperatures. For example, a 0.4mm nozzle is commonly used with PLA and requires a temperature range of 190-220°C, while a 0.8mm nozzle may require a temperature range of 170-200°C.

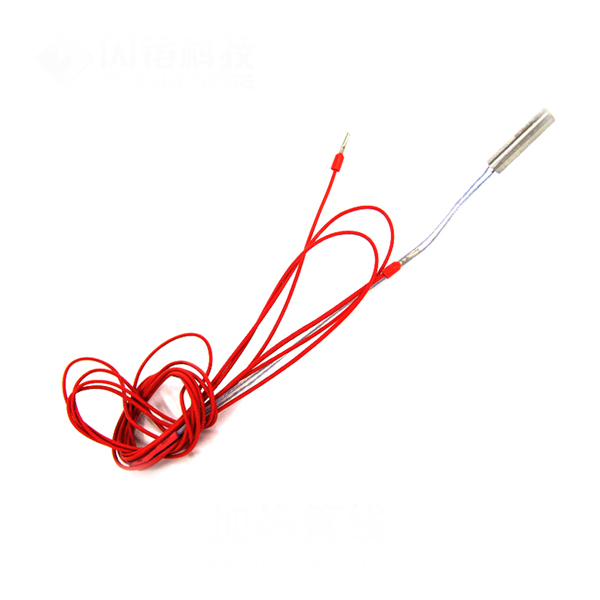

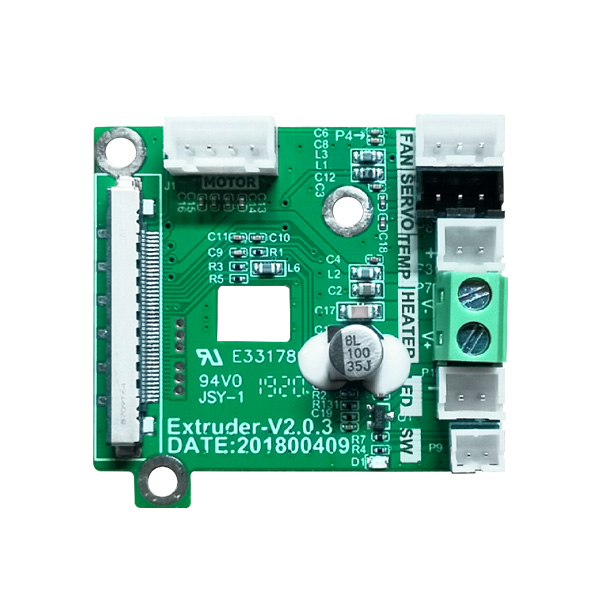

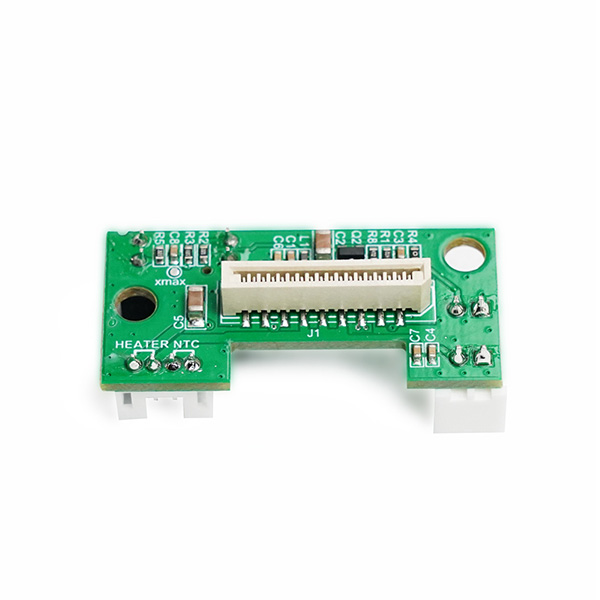

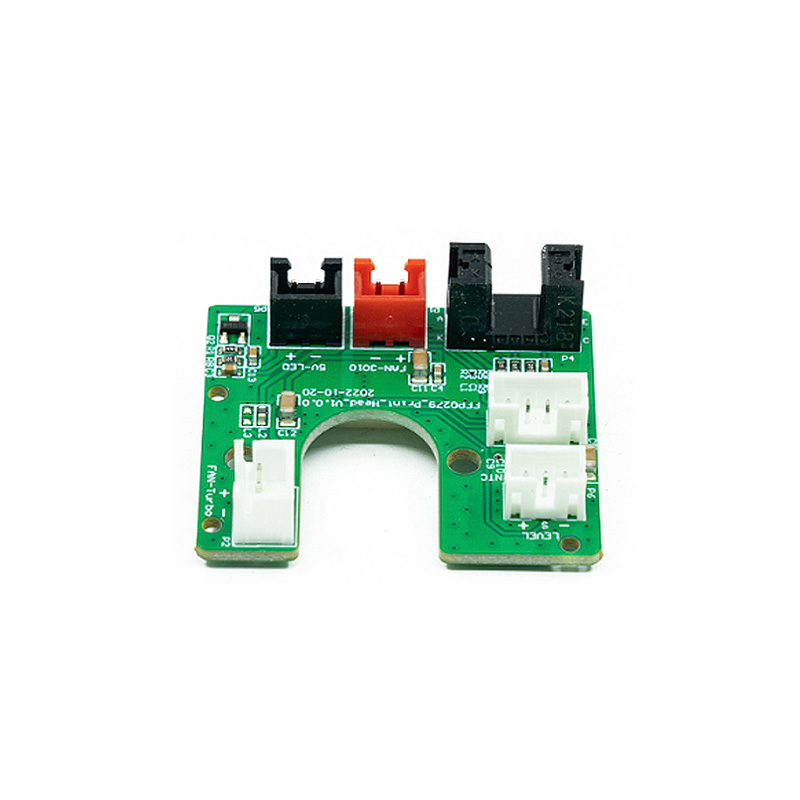

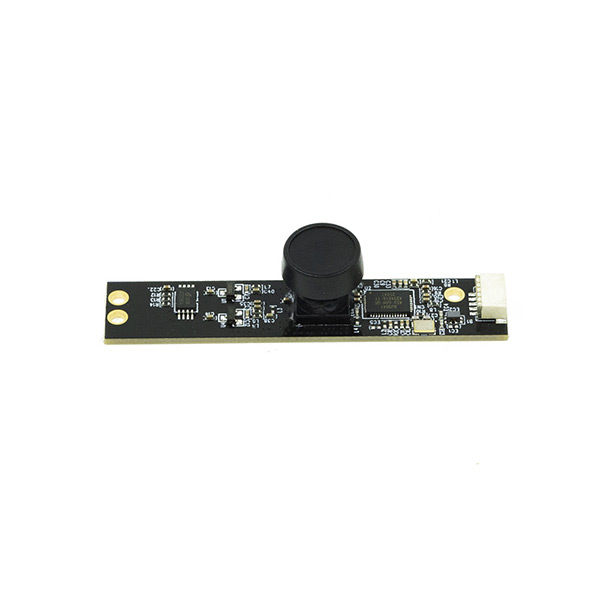

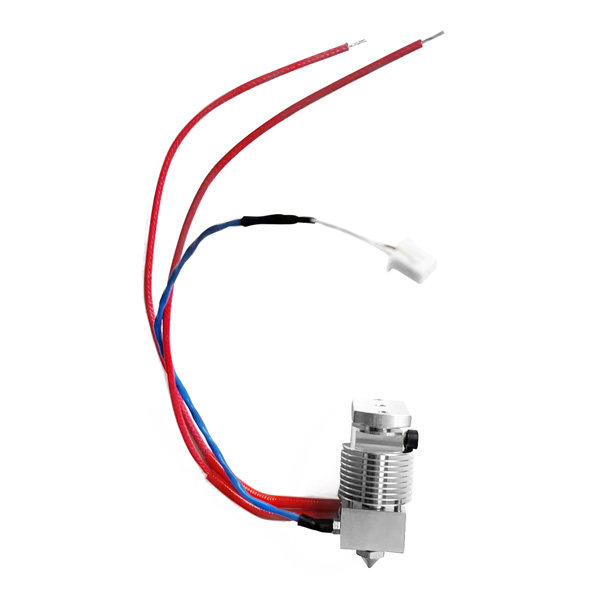

Using a Reliable Temperature Sensor: A reliable temperature sensor is crucial for achieving optimal PLA temperature. A thermistor or a thermocouple can accurately measure the temperature of the hot end and ensure that the filament is being extruded at the desired temperature range.

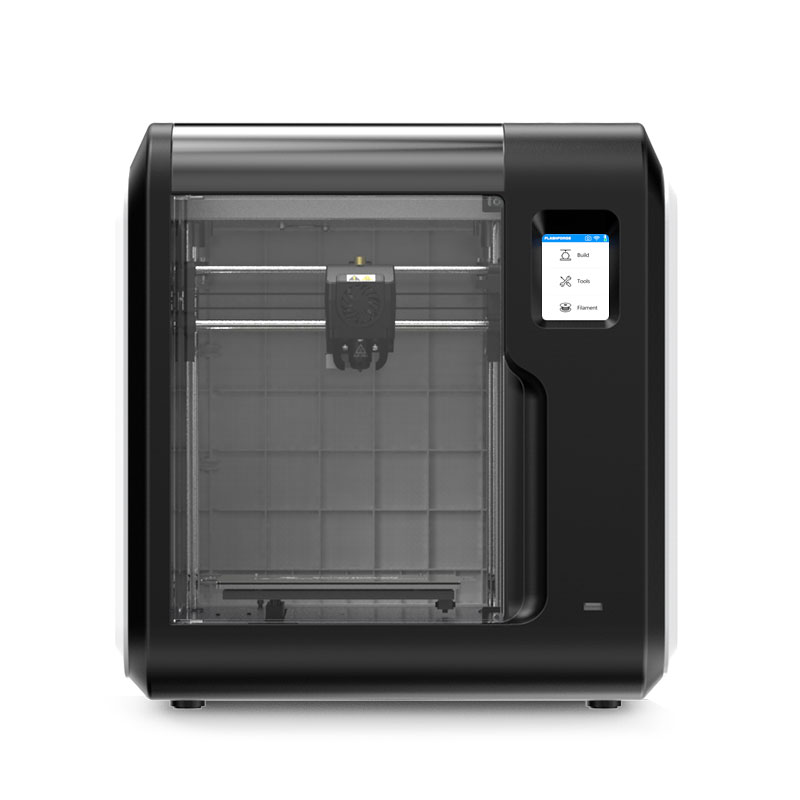

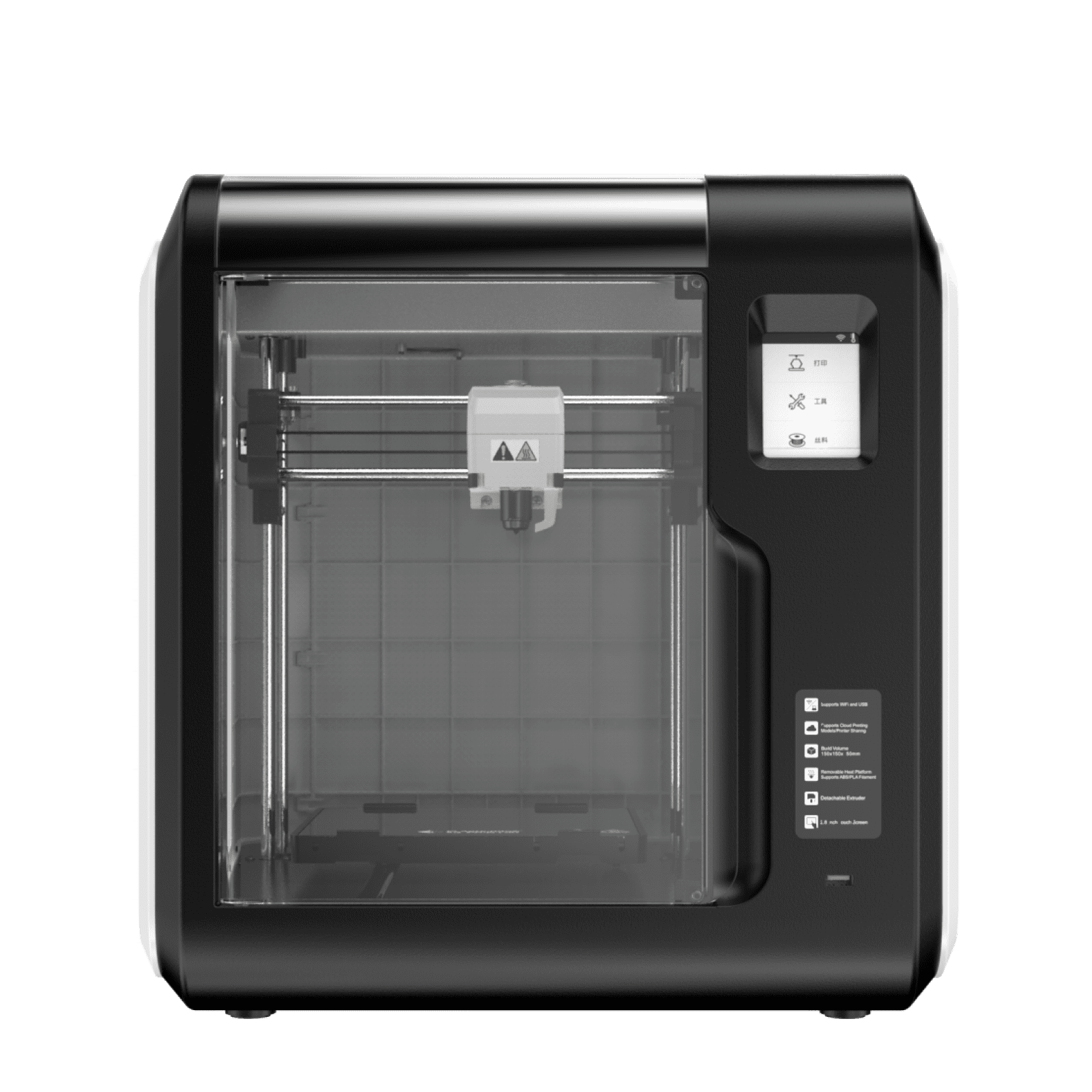

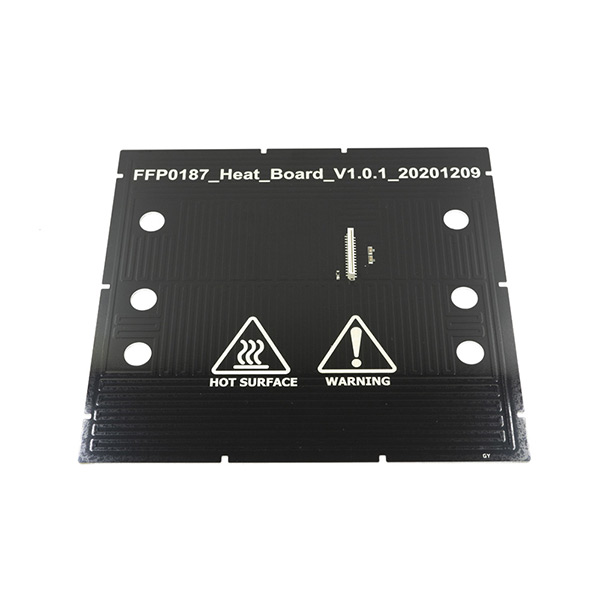

Maintaining a Consistent Printing Environment: PLA is sensitive to changes in temperature and humidity, which can affect the printing process and the final quality of the print. It is important to maintain a consistent printing environment with controlled temperature and humidity levels to achieve optimal PLA temperature. This can be done by using a 3D printer enclosure or printing in a controlled environment with stable temperature and humidity levels.

Conclusion

In conclusion, finding the optimal temperature for PLA filament is crucial to achieve high-quality prints with good strength and durability. Experimenting with different temperature settings and performing calibration tests can help you find the best temperature range for your specific printing needs. It's important to choose the right nozzle size and use a reliable temperature sensor to ensure accurate readings. Additionally, maintaining a consistent printing environment, such as controlling the ambient temperature and humidity, can also improve the overall printing results. With these tips and techniques, you can achieve the best possible PLA prints and take your 3D printing projects to the next level.

Looking to unleash your creativity with 3D printing but don't know where to start? Say hello to Flashforge Shop! Our expert team will guide you through the world of 3D printing and help you find the 3D printer that fits your needs and budget. With unbeatable prices and top-notch service, we're your one-stop-shop for all things 3D printing.