Adventurer 5MP, From US$499 SHOP NOW

Data loading...

Checkout

Checkout

Are you sure to delete this item?

Matching Discounts

Matching Discounts

Data loading...

English

English

4.8 100,000+ Creators

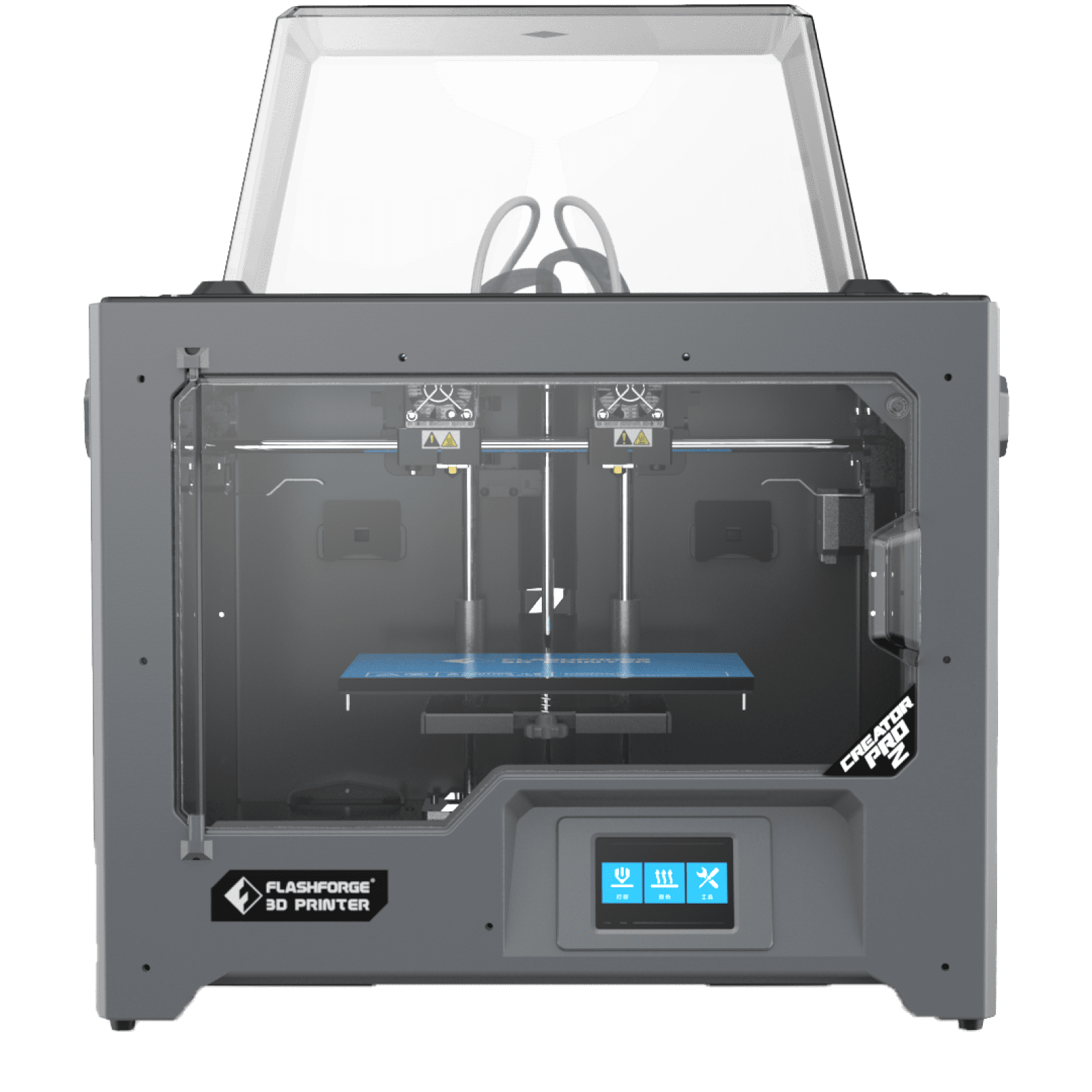

Flashforge Creator 3 Pro 3D Printer

SHIP TO

SHIP TO

-

South Africa

- Algeria

- Angola

- Benin

- Botswana

- Burkina Faso

- Burundi

- Cameroon

- Cape Verde

- Central African Republic

- Chad

- Comoros

- Cote D'Ivoire

- Djibouti

- Egypt

- Equatorial Guinea

- Eritrea

- Ethiopia

- Gabon

- Gambia

- Ghana

- Guinea

- Guinea-Bissau

- Kenya

- Lesotho

- Liberia

- Libya

- Madagascar

- Malawi

- Mali

- Mauritania

- Mauritius

- Morocco

- Mozambique

- Namibia

- Niger

- Nigeria

- Senegal

- Seychelles

- Sierra Leone

- Swaziland

- The Democratic Republic Of The Congo

- The Republic of Congo

- Togo

- Tunisia

- Uganda

- United Republic of Tanzania

- Zambia

- Zimbabwe

-

Singapore

-

Malaysia

-

Thailand

-

Saudi Arabia

-

United Arab Emirates

- Afghanistan

- Armenia

- Azerbaijan

- Bahrain

- Bangladesh

- Brunei

- Burma

- Cambodia

- Cyprus

- East Timor

- Georgia

- Hong Kong(China)

- India

- Indonesia

- Iran

- Iraq

- Israel

- Japan

- Jordan

- Kazakhstan

- Korea

- Kuwait

- Kyrghyzstan

- Lao People's Democratic Republic

- Lebanon

- Macao(China)

- Maldives

- Mongolia

- Nepal

- North Korea

- Oman

- Pakistan

- Philippines

- Qatar

- Sri Lanka

- Syrian Arab Republic

- Taiwan(China)

- Tajikistan

- the Kingdom of Bhutan

- Turkey

- Uzbekistan

- Vietnam

- Yemen

-

United Kingdom

-

France

-

Spain

-

Germany

-

Netherlands

- Albania

- Andorra

- Austria

- Bailiwick of Guernsey

- Belarus

- Belgium

- Bosnia and Herzegovina

- Bulgaria

- Croatia

- Czech Republic

- Denmark

- Estonia

- Faroe Islands

- Finland

- Gibraltar

- Greece

- Hungary

- Iceland

- Ireland

- Italy

- Jersey

- Kosovo

- Latvia

- Liechtenstein

- Lithuania

- Luxembourg

- Malta

- Monaco

- Montenegro

- North Macedonia

- Norway

- Poland

- Portugal

- Republic of Moldova

- Romania

- Russian Federation

- San Marino

- Serbia

- Sint Maarten (Netherlands)

- Slovakia

- Slovenia

- Sweden

- Switzerland

- Ukraine

-

United States

-

Canada

-

Mexico

- American Samoa

- Anguilla

- Antigua and Barbuda

- Aruba

- Barbados

- Belize

- Bermuda

- British Virgin Islands

- Cayman Islands

- Costa Rica

- Cuba

- Curacao

- Dominican Republic

- El Salvador

- Grenada

- Guadeloupe

- Guatemala

- Haiti

- Honduras

- Jamaica

- Martinique

- Montserrat

- Nicaragua

- Panama

- Puerto Rico

- Saint Barthelemy

- Saint Lucia

- Saint Vincent and the Grenadines

- The Commonwealth of The Bahamas

- Trinidad and Tobago

- Turks and Caicos Islands

- U.S.Virgin Islands

-

Australia

-

New Zealand

- Cook Islands

- Fiji

- Guam

- Kiribati

- Micronesia

- Nauru

- New Caledonia

- Niue

- Palau

- Papua New Guinea

- Samoa

- Solomon Islands

- The Republic of Marshall Islands

- Tonga

- Tuvalu

- Vanuatu

- Argentina

- Bolivia

- Brazil

- Chile

- Colombia

- Ecuador

- Falkland Islands (Islas Malvinas)

- Guyana

- Guyane French

- Netherlands Antilles

- Paraguay

- Peru

- Suriname

- Uruguay

- Venezuela

Select Package Type

Select Package Type

- IDEX system.

- Nozzle temperature ups to 320℃.

- Multi print modes.

If any parts are broken within the warranty period, Flashforge will send free parts. If any parts are broken and cannot be repaired, Flashforge will replace them for you or you may return them for a refund.

Read the full warranty policy here.

Build tape/Build plate/SD card/USB stick/USB cable/Filament/Filament spool/Glue/Resin vat/Film/Resin Bucket/ Gloves/ Plastic scraper/ Metal scraper/Brush/Allen wrench (2.5mm*1/3mm*1/5mm*1)/Stamping wrench/Tools bag/Accessorie

Flashforge accepts returns for Flashforge 3D printers within 30 days of receipt of delivery without any reasons.

If the return is due to logistics damage, low product quality or Flashforge sent the wrong goods, Flashforge bears the freight cost, otherwise Buyer bears the freight cost.

Please contact us at service01@flashforge.com if you want to ask for a return or exchange service.

Get 1% Cashback

With FlashForge Credit

Main features:

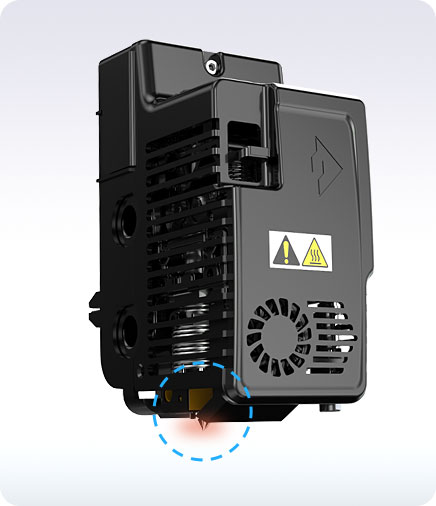

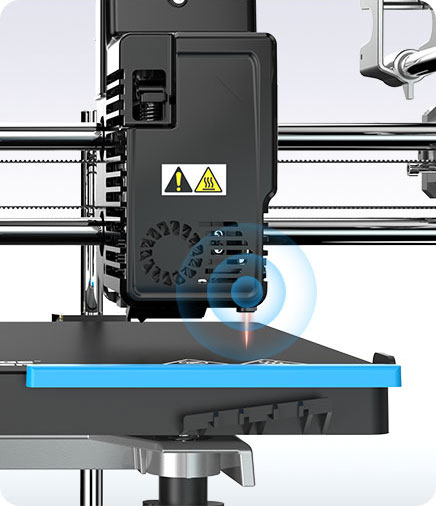

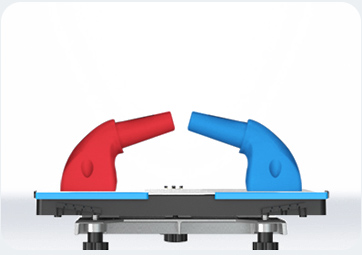

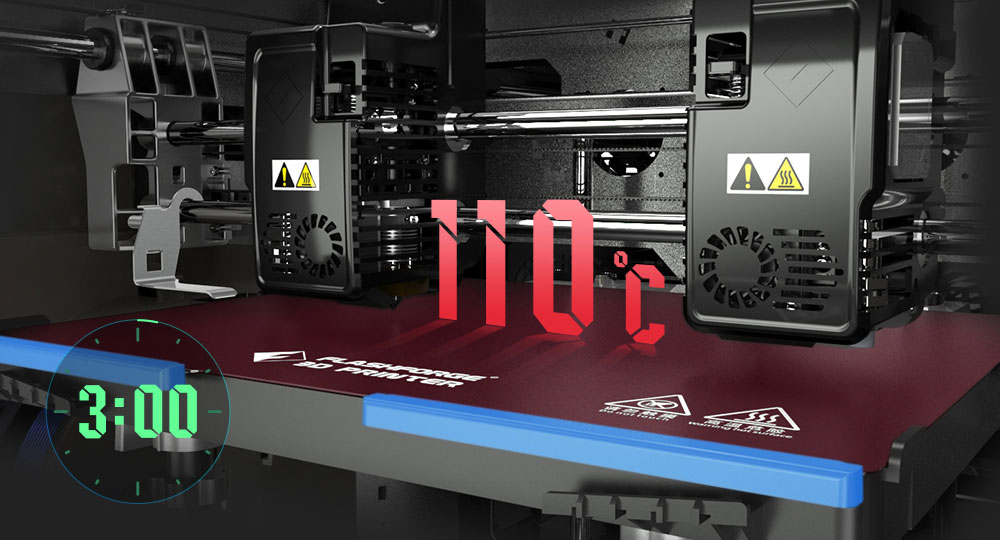

- Optimized extruder assembly of Flashforge creator 3 pro: Nozzle reach up to 200℃ in 1 minute; Brand new cooling fan structure for better printing effects; Upgraded extruder sensor for better build plate leveling.

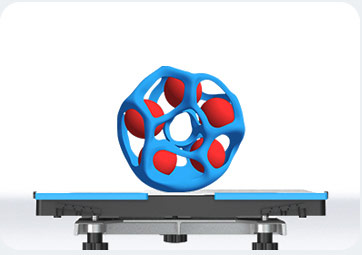

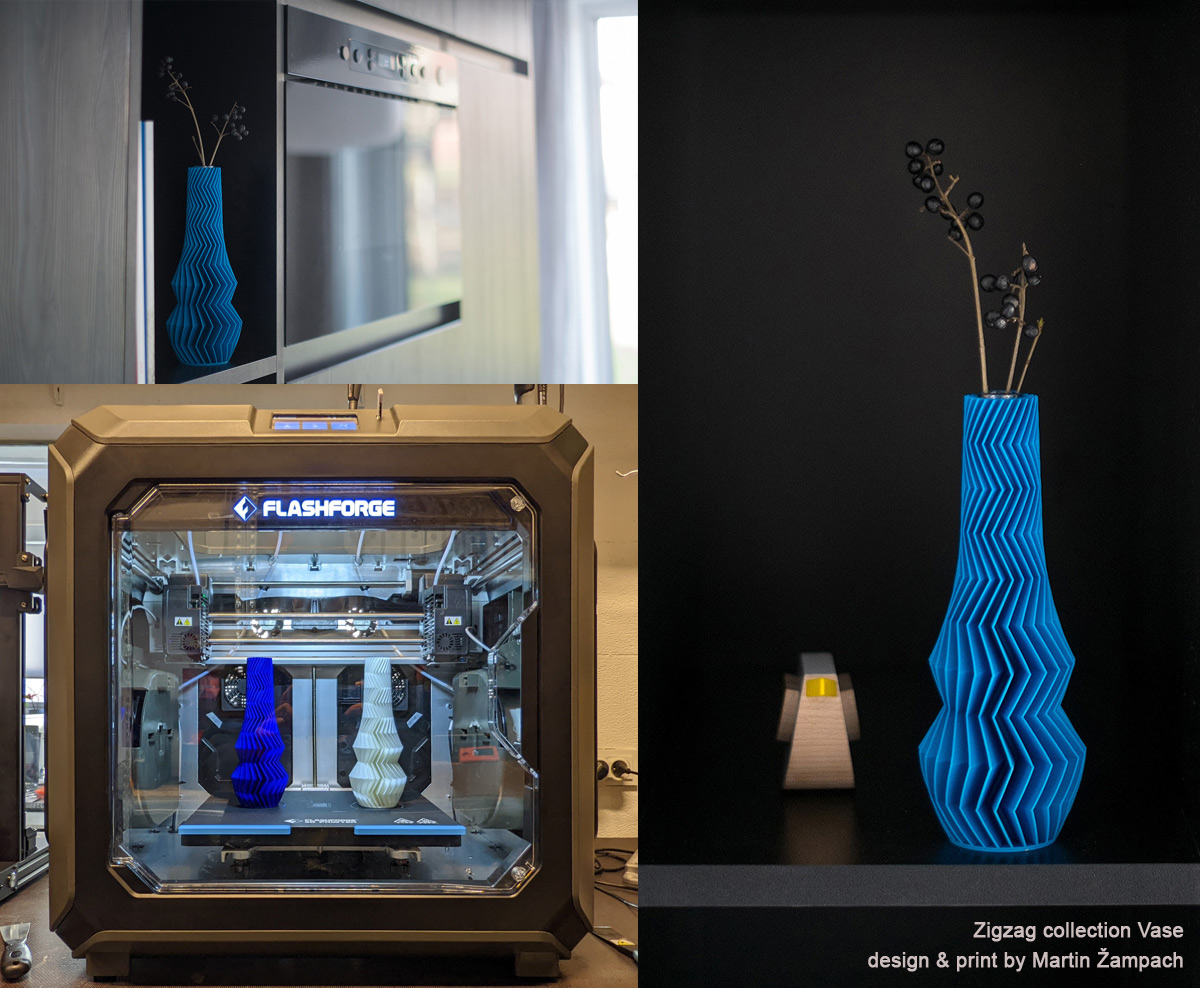

- Independent Dual Extruder system allows dual printing, greatly cut down print time.

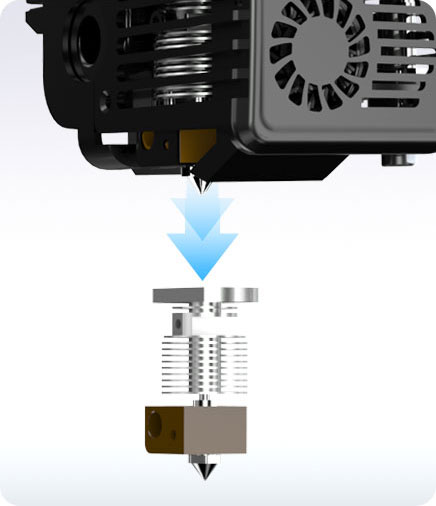

- Creator 3 Pro extruder can be heated up to 320℃. Support 0.4/0.6/0.8mm stainless steel nozzles; 0.4/0.6/0.8mm carbon steel nozzles for carbon fiber materials.

- 300*250*200mm build volume.

- Fast heating of build platform. Flashforge Creator 3 Pro reaches up to 110℃ just in 3 minutes.

- Filament supported: PLA, ABS, PVA, PETG, HIPS, PA, PC, ASA, PACF.