Welcome, beginners! Have you ever wondered how some of the most intricate designs, from medical implants to aerospace components, are created? The answer lies in the fascinating world of advanced 3D printing techniques. With its ability to produce highly complex shapes and geometries, 3D printing has revolutionized the way we design and manufacture products.

In fact, the global 3D printing market size is projected to reach $40.8 billion by 2024.

So, if you're looking to stay ahead of the curve in the world of manufacturing, understanding advanced 3D printing techniques is a must.In this article, we'll delve into the importance of these techniques for intricate designs and explore some impressive examples of what's possible with advanced 3D printing. So let's get started!

Advanced 3D Printing Techniques

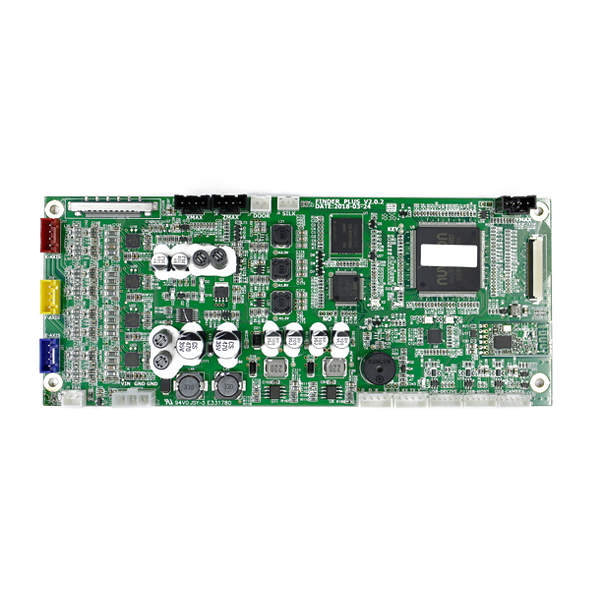

Advanced 3D printers have revolutionized the way we create intricate designs with a high level of precision and accuracy.

Here are some of the most popular advanced 3D printing techniques:

Multi-material 3D printing:

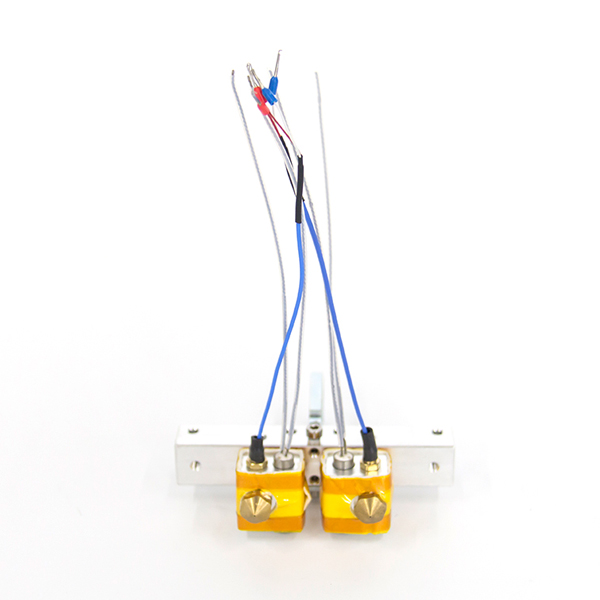

Multi-material 3D printing allows the printing of objects using different materials in a single print job. This is particularly useful when printing objects with intricate designs that require different properties, such as stiffness, flexibility, or color.

By using multiple materials, designers can create complex geometries, textures, and patterns that would otherwise be impossible to achieve with a single material.

For instance, a prosthetic hand can be printed with rigid materials for structural support and flexible materials for a comfortable fit.

Prosthetic hand made with Multiple materials.

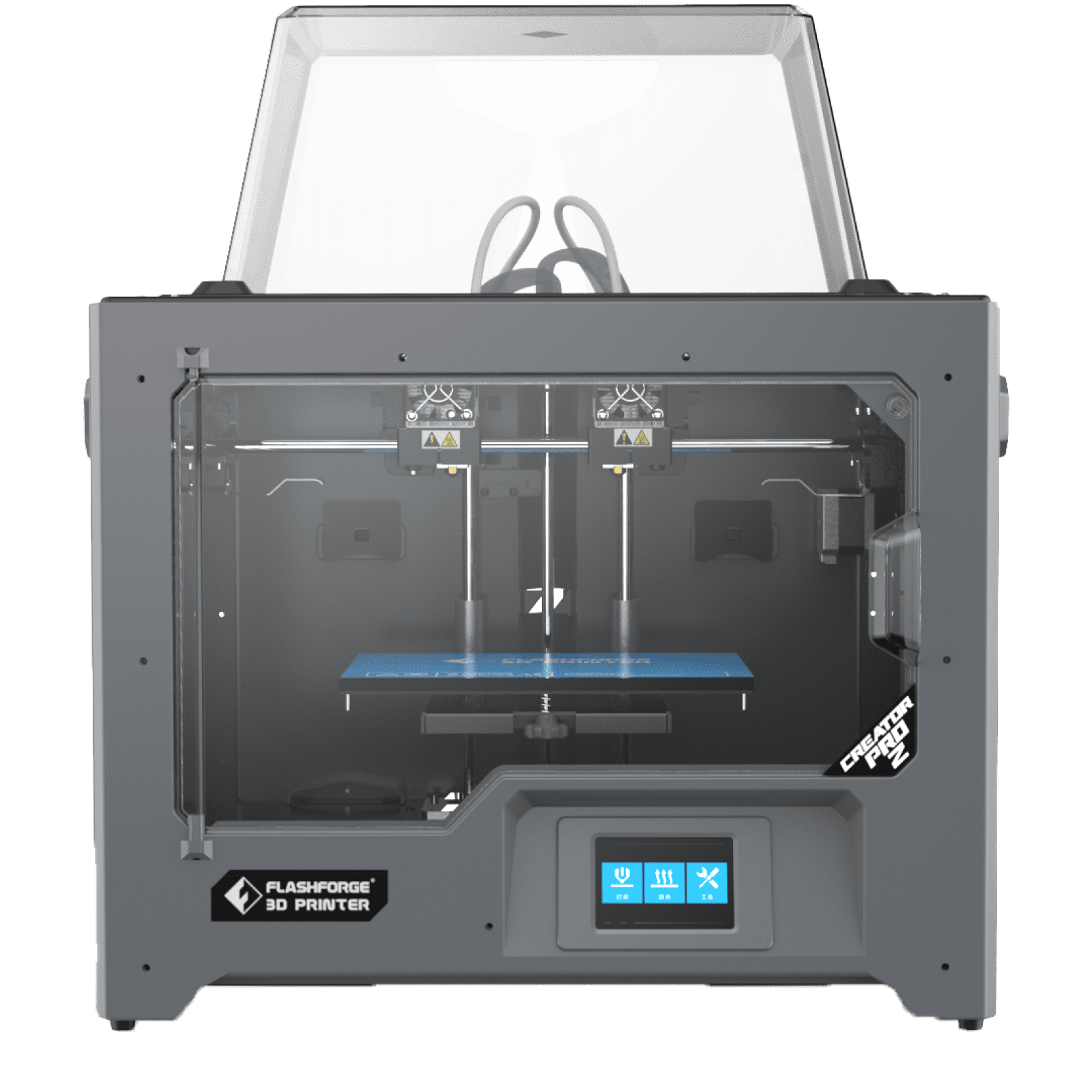

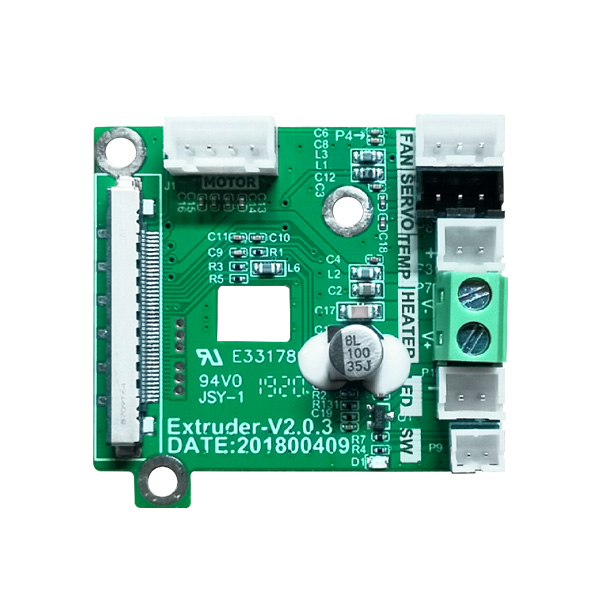

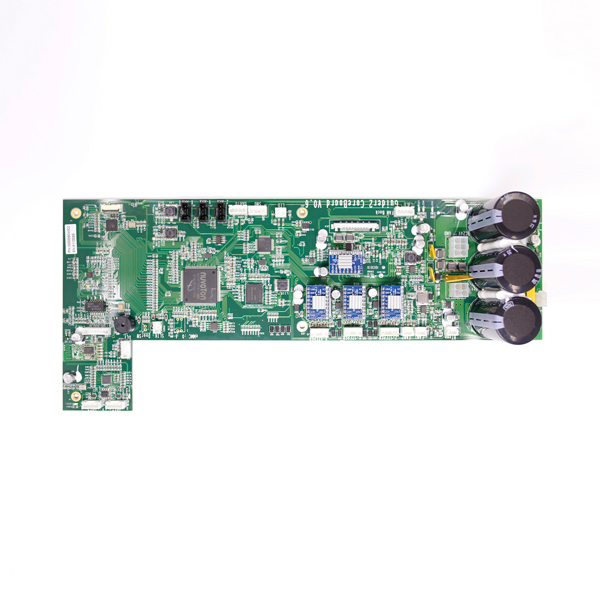

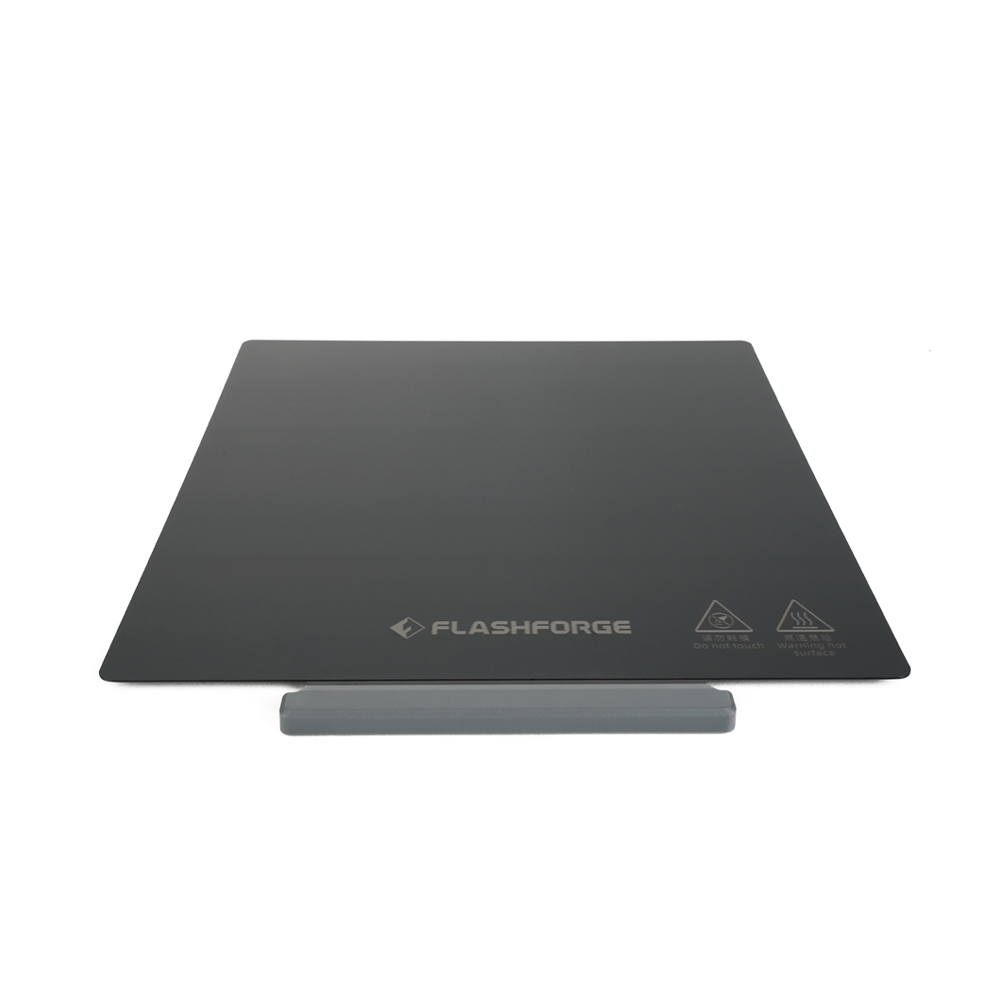

Pro-tip: If you're using a multi-material 3D printer like the Flashforge Creator Pro, make sure to check the compatibility of the materials you're planning to use. Some materials may not be suitable for use with other materials or may require specific print settings.

Multi-axis printing:

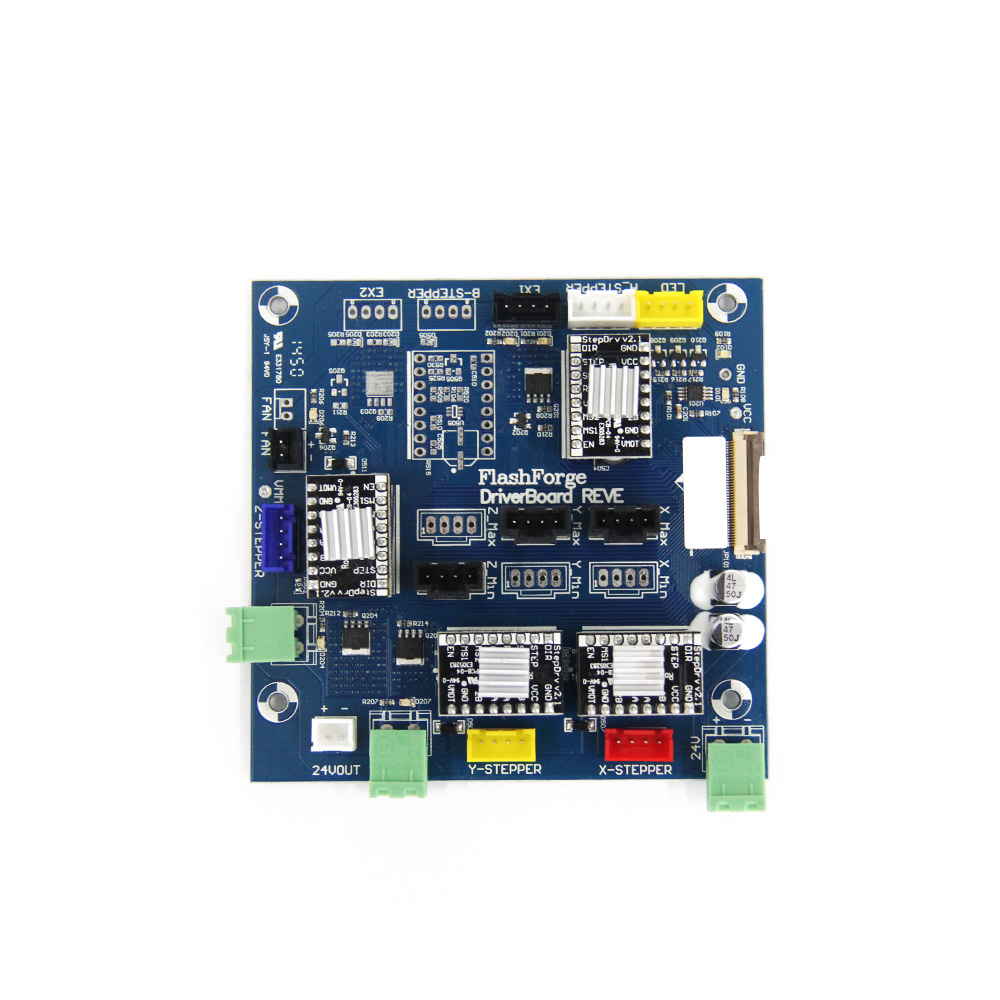

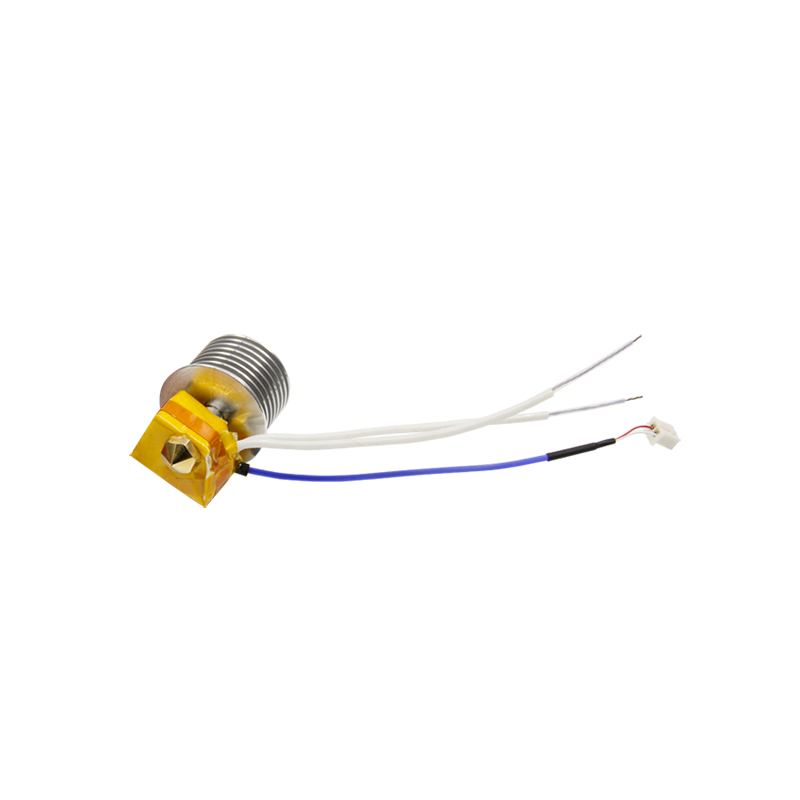

Multi-axis printing allows the 3D printer to print in multiple axes, enabling the creation of complex geometries and overhangs that would otherwise be impossible with traditional printing methods. Multi-axis printers can move the print head along multiple axes, including X, Y, and Z, as well as additional rotation and tilting axes. This technique can be particularly useful when printing intricate models such as sculptures or architectural models.

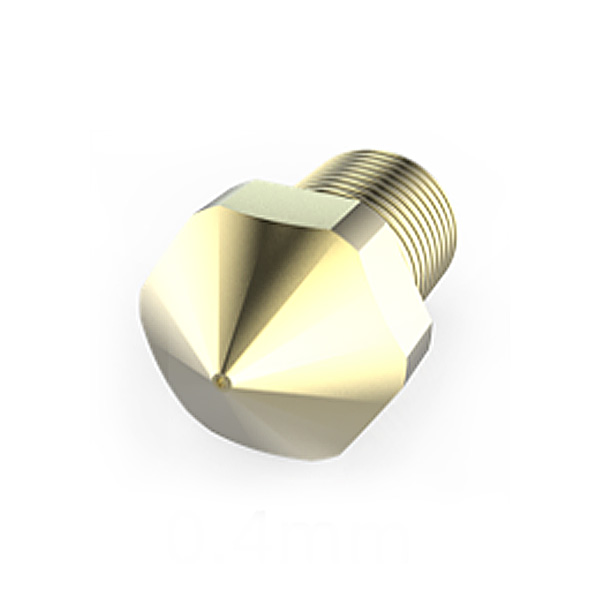

Pro-tip: When printing with multi-axis printers, it is essential to optimize the print settings to achieve the best quality and precision. This may include adjusting the print speed, layer height, and nozzle diameter.

Multi-axis 3D Printing

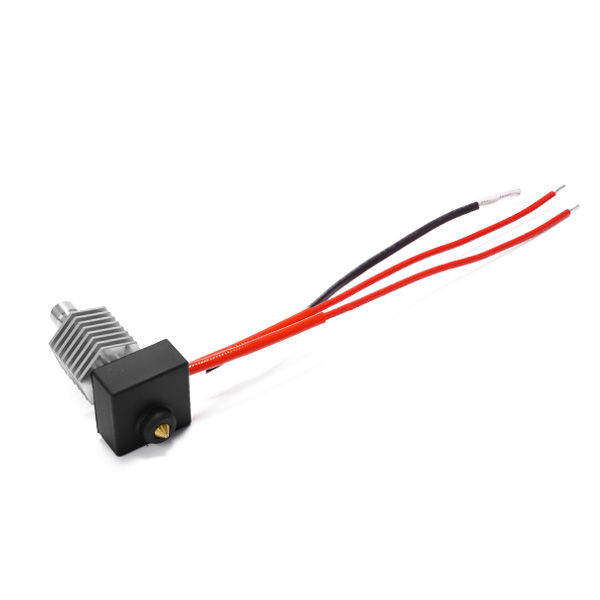

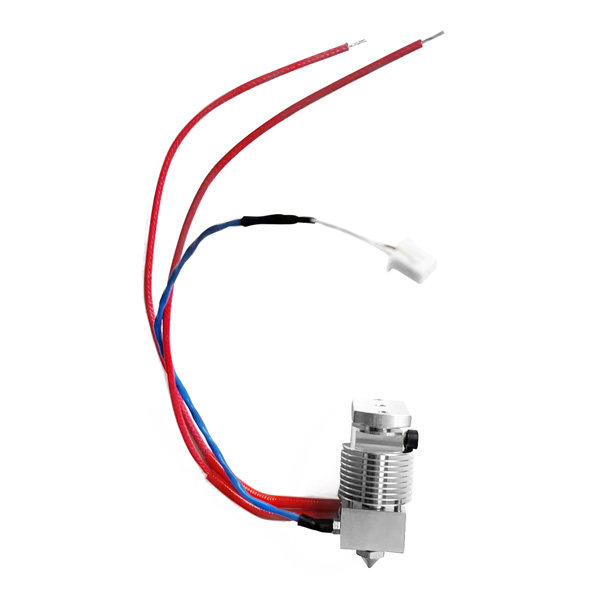

Dual extrusion printing:

Dual extrusion printing is a technique that involves printing with two different materials or colors simultaneously, resulting in complex and colorful prints. This technique is particularly useful when printing objects that require different properties or colors, such as a phone case with a hard outer shell and a soft inner lining. Dual extrusion printers can use two extruders to print two materials or colors at the same time, resulting in faster print times and reduced material waste.

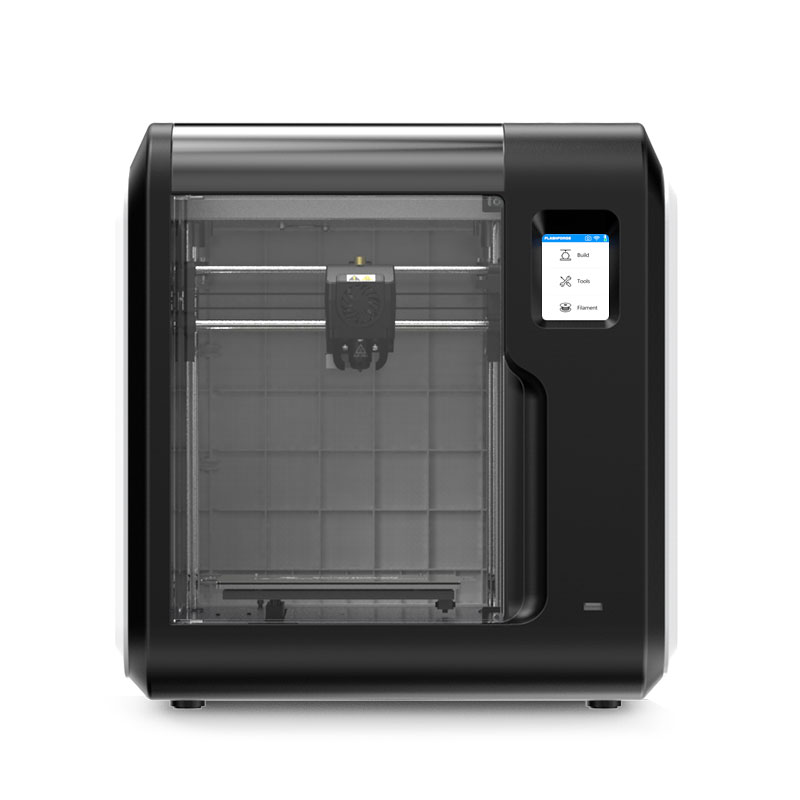

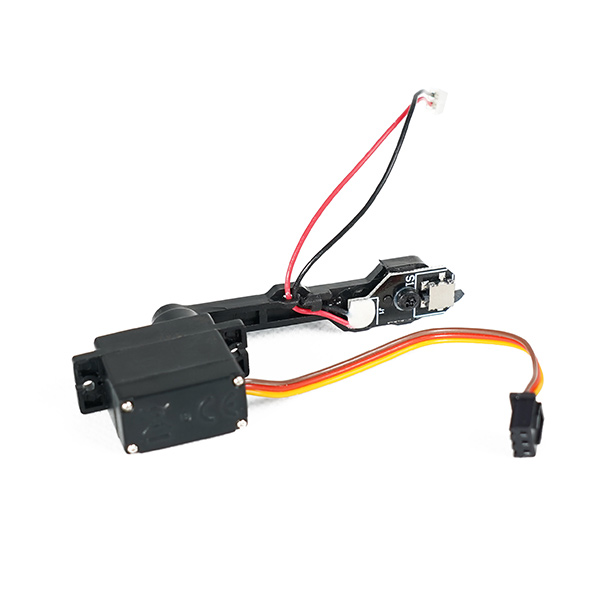

Pro-tip: When using dual extrusion printing, make sure to choose materials that have similar melting points and viscosity to avoid clogging your print heads. Also, consider using a printer with a built-in filament detection system, like the Flashforge Dreamer NX, to prevent the printer from running out of filament mid-print.

Dual extruder 3D Printing with Flashforge Creator pro

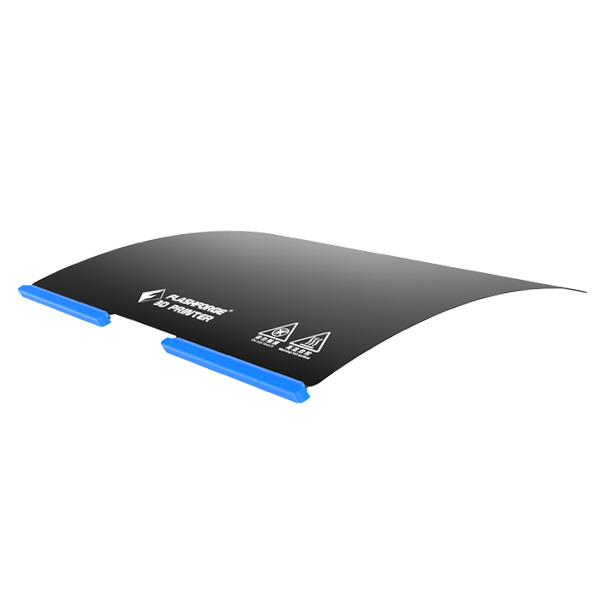

Support material printing:

Support material printing allows the printer to print support structures that can be removed after printing to achieve intricate designs. This is particularly useful when printing objects with overhangs or complex geometries that would otherwise collapse during printing. The support material can be printed in a different material, which can be dissolved or removed manually after printing. For instance, support structures for a 3D printed statue can be printed in a water-soluble material, which can be easily washed away after printing.

Pro-tip: When printing with support material, it is essential to optimize the support structures' design and placement to minimize material usage and maximize print quality. Additionally, it is crucial to ensure that the support material can be easily removed without damaging the final print.

Support Structures for 3D Printed statues.

Some other advanced 3D Printer techniques include:

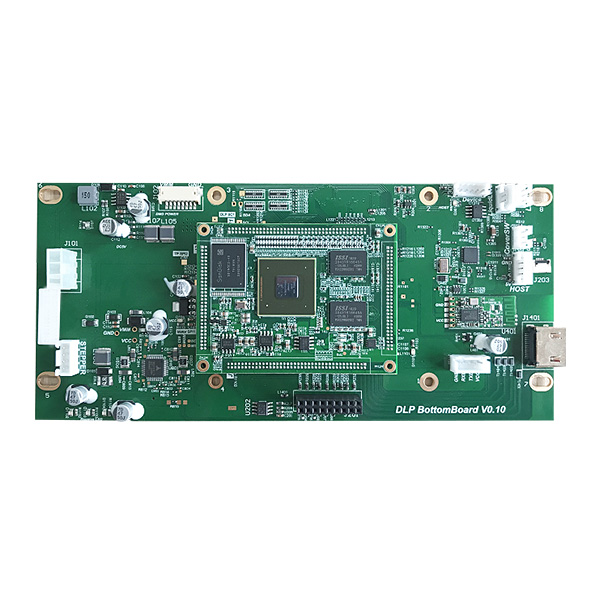

Hybrid 3D Printing: This technique combines two or more types of 3D printing processes to create a single object. For example, combining FDM and SLA printing can create an object with both solid and transparent sections.

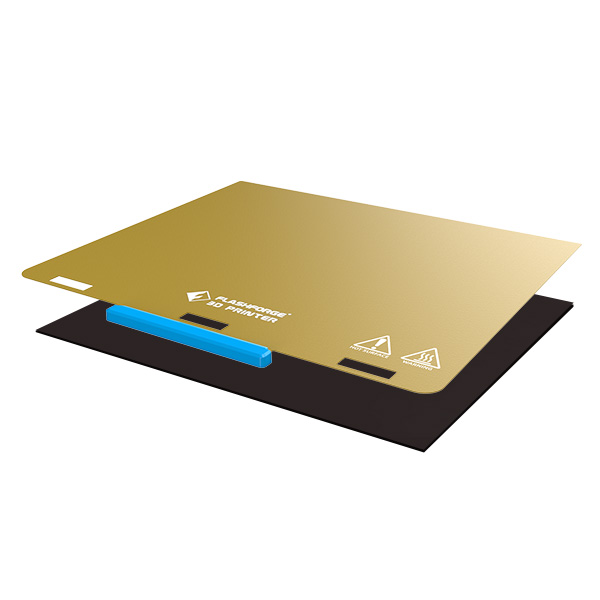

Continuous 3D Printing: This technique allows for the continuous production of 3D prints without interruption. It involves using a conveyor belt or other mechanism to continuously move the printed object away from the print bed while new layers are added.

Bioprinting: This technique involves using living cells to create 3D printed tissues and organs. It is an emerging field with potential applications in regenerative medicine and drug discovery.

Metal 3D Printing: This technique involves using metal powders or wires to create 3D printed objects. It is commonly used in industrial settings for applications such as aerospace, automotive, and medical devices.

Nanoparticle Jetting: This technique involves jetting tiny droplets of liquid containing nanoparticles onto a surface to create intricate structures with high resolution and accuracy. It is commonly used in the production of electronic components and medical devices.

Case study:

A team of researchers from the University of Southern California used FlashForge Creator Pro 3D printers to create a wearable biosensor. The device was made of two different materials - a rigid plastic and a flexible rubber - which were printed simultaneously using the dual extrusion technique. The rigid plastic was used for the main body of the sensor, while the flexible rubber was used for the straps that secured it to the wearer's wrist.

Without the ability to print with multiple materials, this device would have required multiple steps and materials to produce, making the process more time-consuming and expensive. However, with the FlashForge 3D printer and the multi-material printing technique, the researchers were able to create a functional prototype quickly and efficiently.

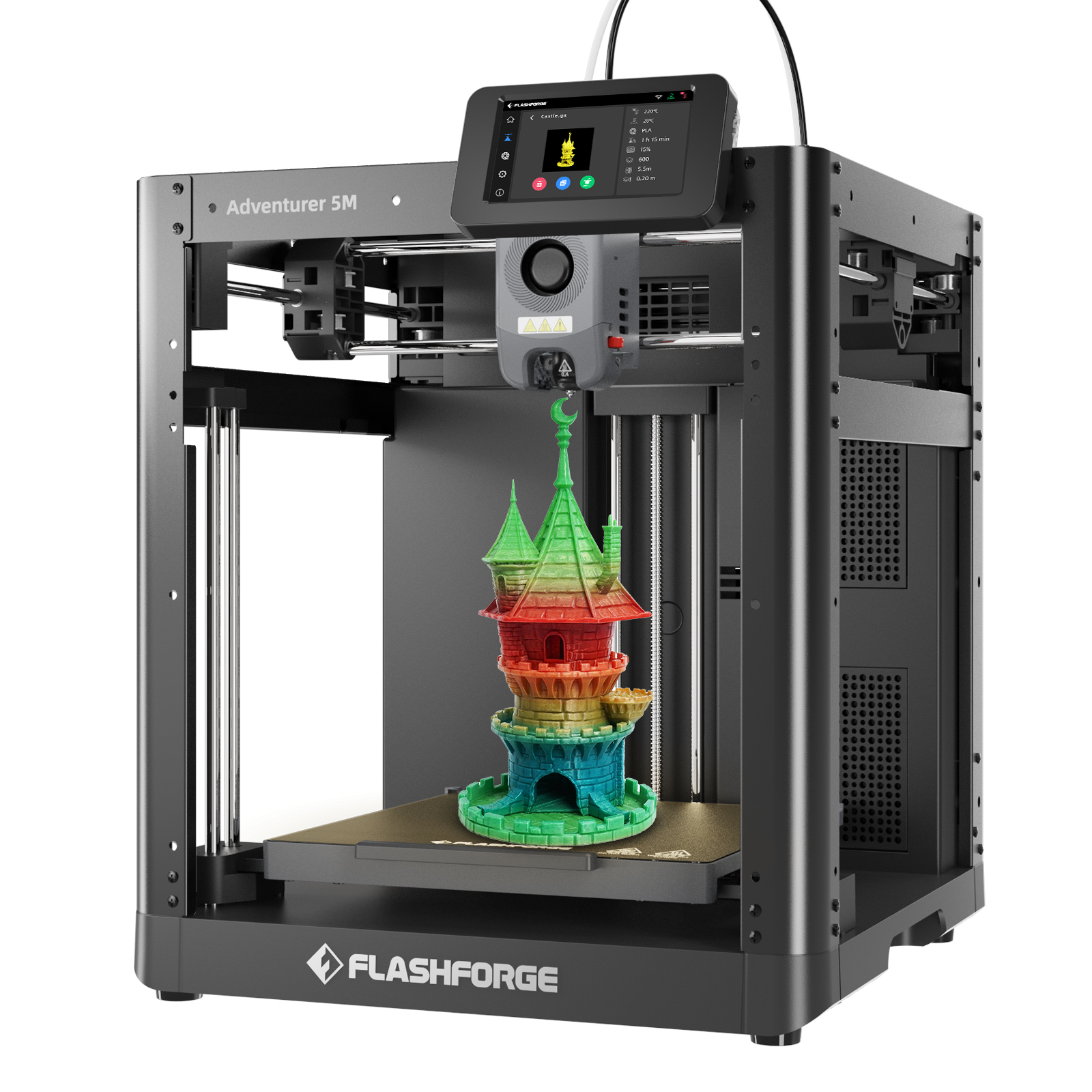

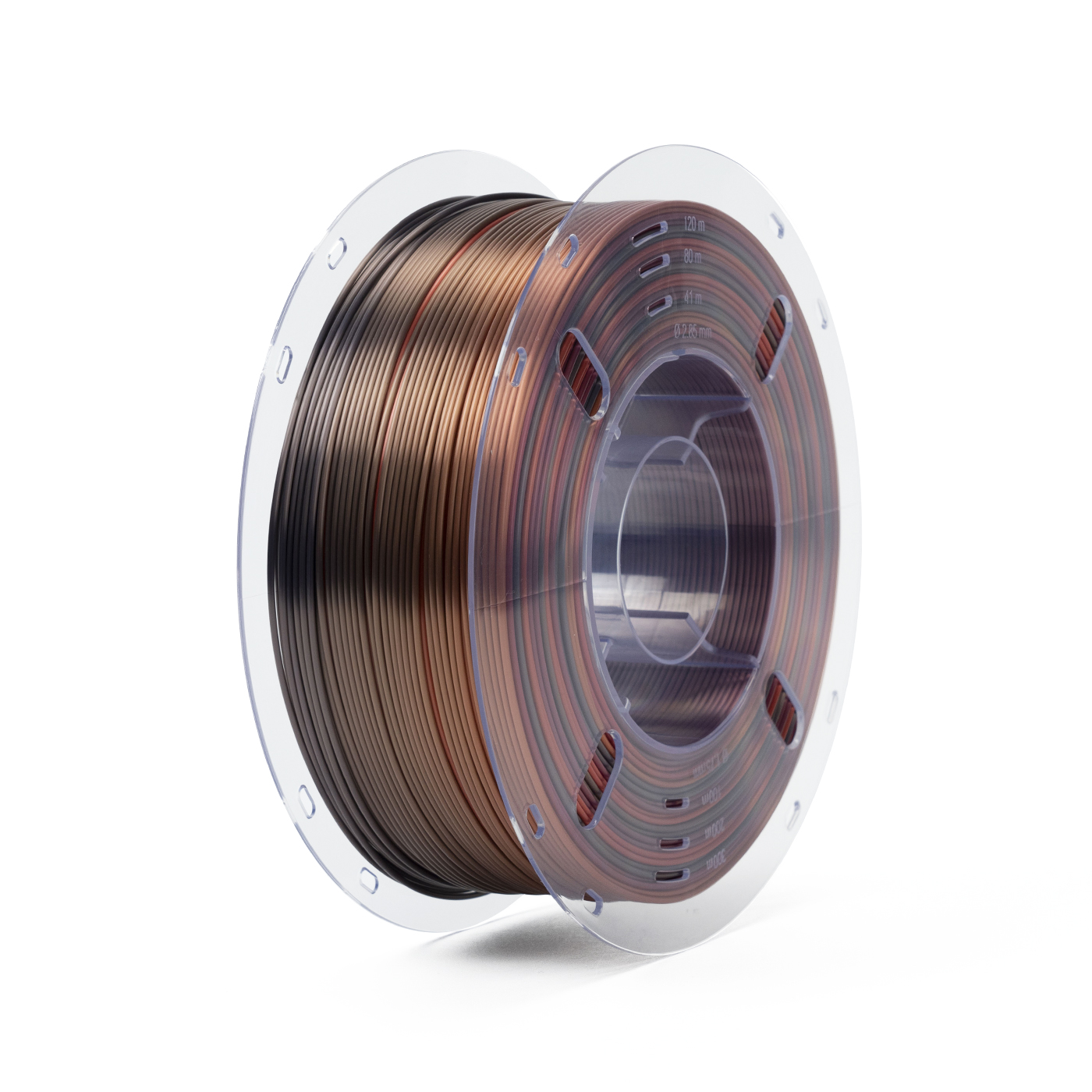

Another Hobbyist, Stephanie Wilkinson printed the dragon on Flashforge Adventurer 4 with triple color filament and advanced techniques such as Multi-axis Printing to create this gorgeous masterpiece.

Final thoughts

In conclusion, advanced 3D printing techniques offer a plethora of benefits and opportunities for creating intricate designs with a high level of precision and accuracy. By using these techniques, designers can push the boundaries of what is possible and create truly unique and innovative objects. However, it is essential to optimize the print settings, select the appropriate materials, and design the support structures carefully to achieve the best quality and precision.

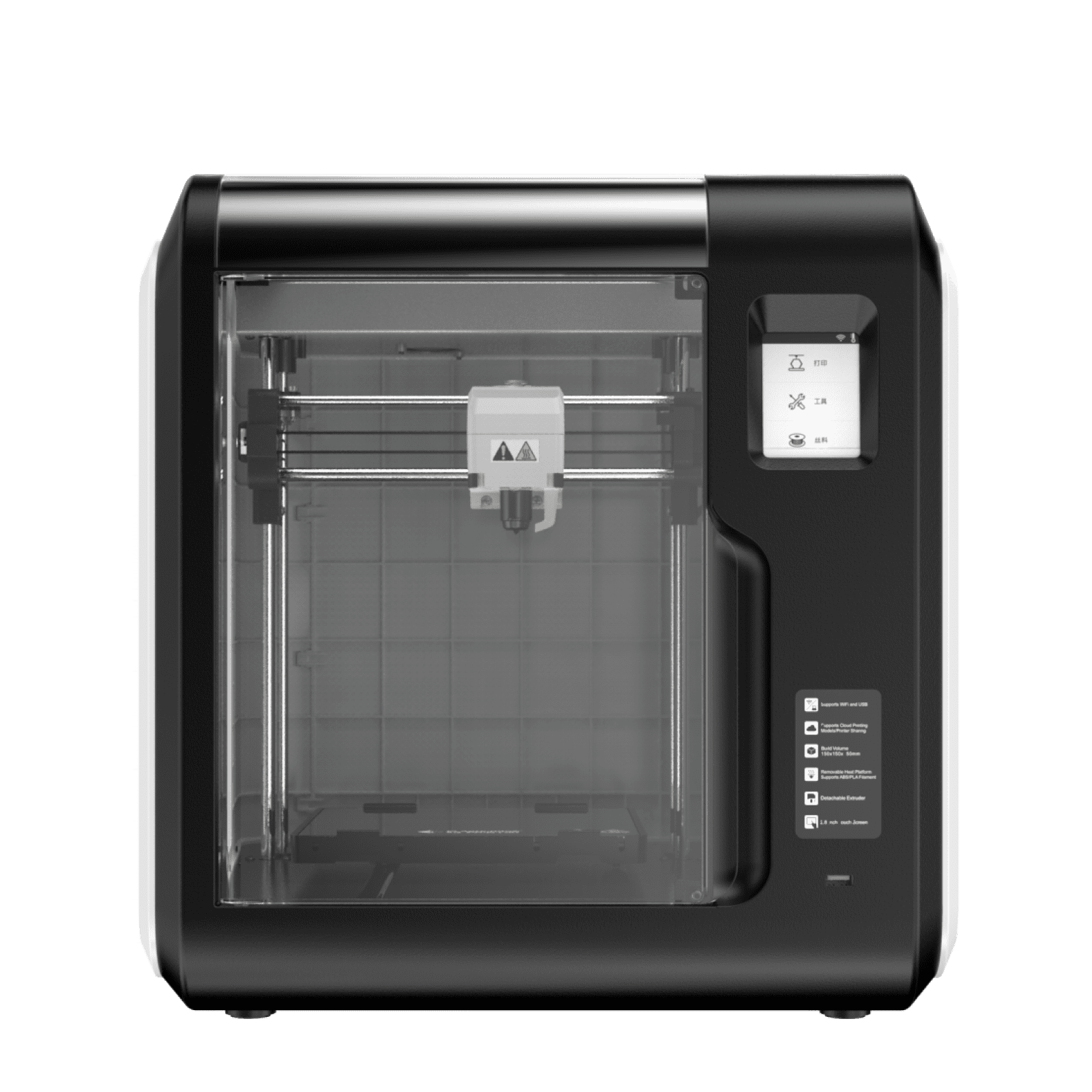

Looking to unleash your creativity with 3D printing but don't know where to start? Say hello to Flashforge Shop! Our expert team will guide you through the world of 3D printing and help you find the 3D printer that fits your needs and budget. With unbeatable prices and top-notch service, we're your one-stop-shop for all things 3D printing.