SLA 3D printing has transformed the product prototyping and manufacturing industry by offering a budget-friendly and efficient method to produce high-quality prints. Nevertheless, like any technology, there are common mistakes that users can make, which can result in frustrating issues.

So therefore, it's important for both novices and experienced users to be aware of these mistakes and take measures to prevent them to ensure optimal performance of their SLA 3D printer and prints.

In this article we will cover the five most common mistakes to avoid when using an SLA 3D printer, including incorrect calibration and substandard post-processing. We will provide a comprehensive explanation of each mistake, why it's problematic, and how to avoid it. These tips will help you attain your goals and create high-quality prints effortlessly, whether it's for personal use or a professional project. So, let's delve into the five common mistakes to avoid when using an SLA 3D printer.

Mistake #1: Incorrect Calibration

Calibration is the process of adjusting the SLA 3D printer's settings to ensure that it operates optimally and produces high-quality prints. Calibration is essential to avoid common issues such as layer shifting, under or over-extrusion, and warping, among others.

Signs that your SLA 3D printer may not be correctly calibrated include:

- Prints with poor dimensional accuracy

- Visible layer lines

- Inconsistent layer adhesion

- Print not sticking or resin being over-cured due to the printer nozzle or bed being too close or too far away

To calibrate your SLA 3D printer, you can follow these steps:

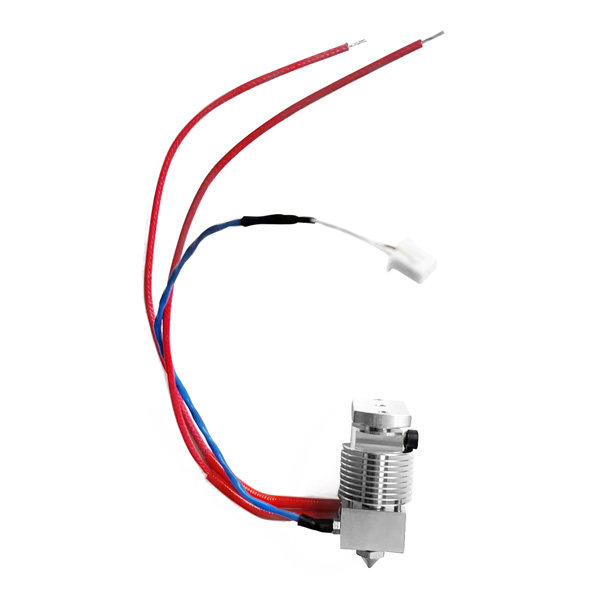

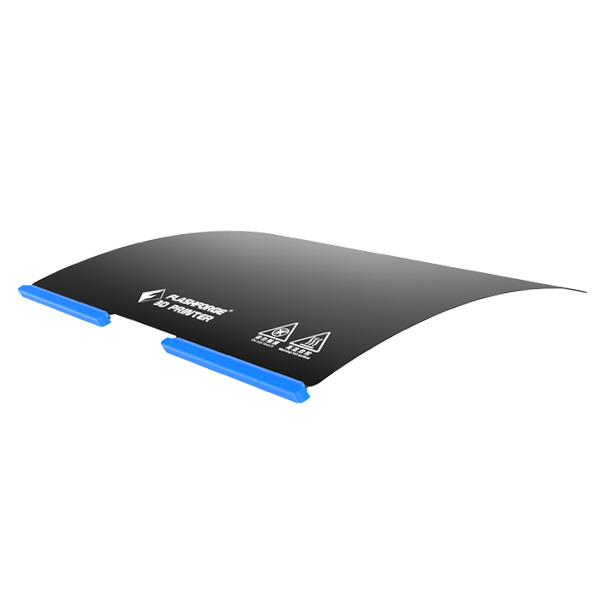

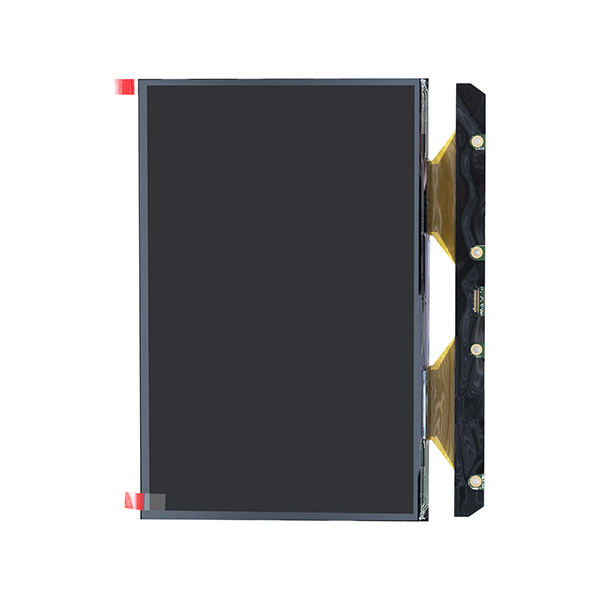

- Level the build plate to ensure it's parallel to the printer's LCD panel

- Adjust the height of the build plate so that the distance between the build plate and the nozzle is optimal

- Adjust the exposure time, layer thickness, and lift speed to ensure that the print quality is at its best

Calibration is very crucial for achieving optimal performance and high-quality prints from your SLA 3D printer. By following the step-by-step guide, you can easily calibrate your printer and avoid common issues that arise.

Let’s look at a case that arose from incorrect bed leveling:

Case: A small 3D printing service provider in the UK had recently invested in a new SLA printer to expand their business. They had followed the manufacturer's instructions for bed leveling and were satisfied with the initial test prints. However, they soon started experiencing issues with print adhesion and quality.

The prints were either sticking too firmly to the build plate, making it difficult to remove them, or not adhering at all, resulting in failed prints. The service provider tried adjusting the exposure time, resin settings, and cleaning the build plate, but the problem persisted.

Upon further inspection, the service provider realized that the bed leveling was incorrect. The build plate was not leveled, and some areas were higher or lower than others. This caused the prints to stick too firmly in some areas or not adhere at all in others.

The service provider immediately re-leveled the build plate according to the manufacturer's recommended process and tested it with several prints. The difference was significant, and the prints were now adhering properly and had a consistent quality.

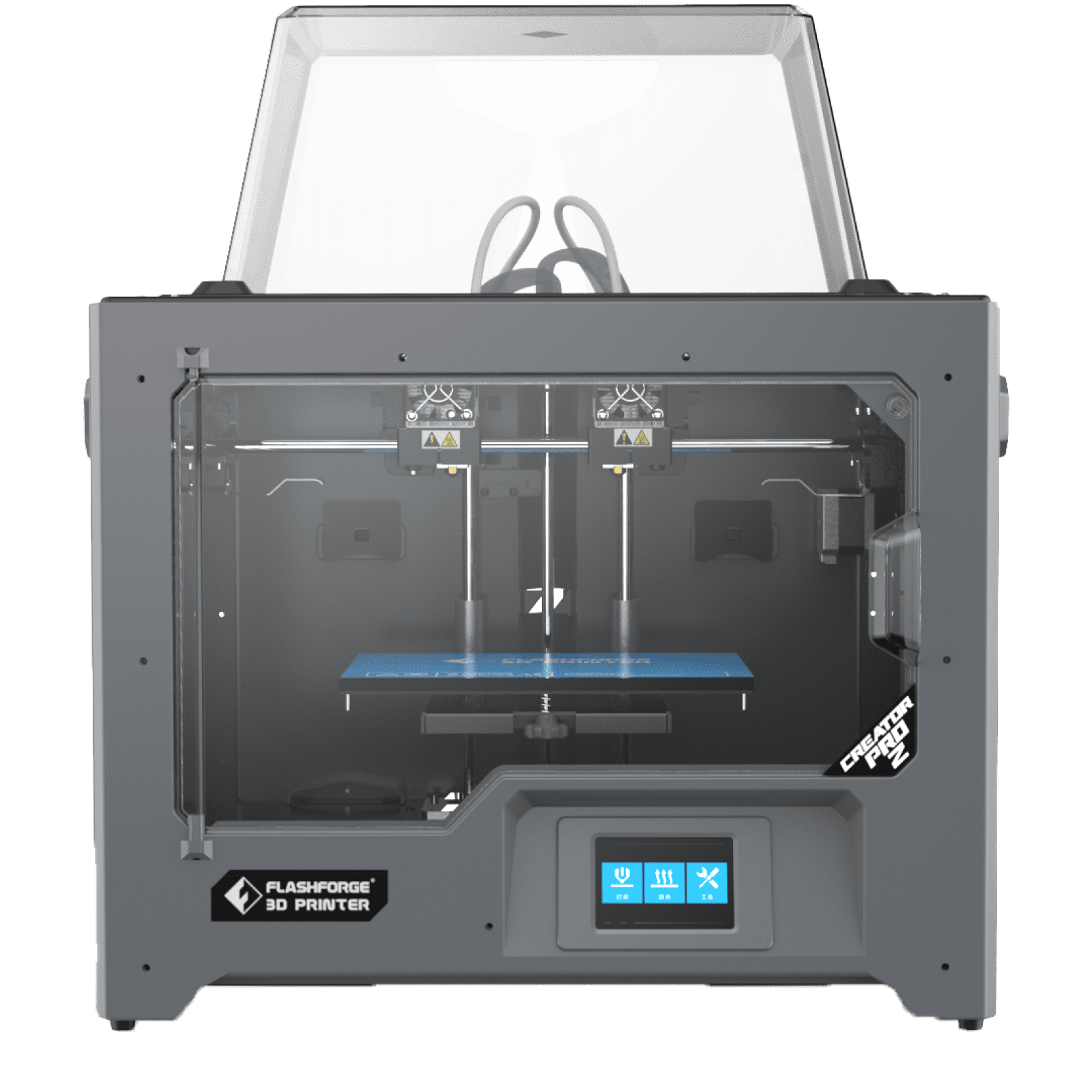

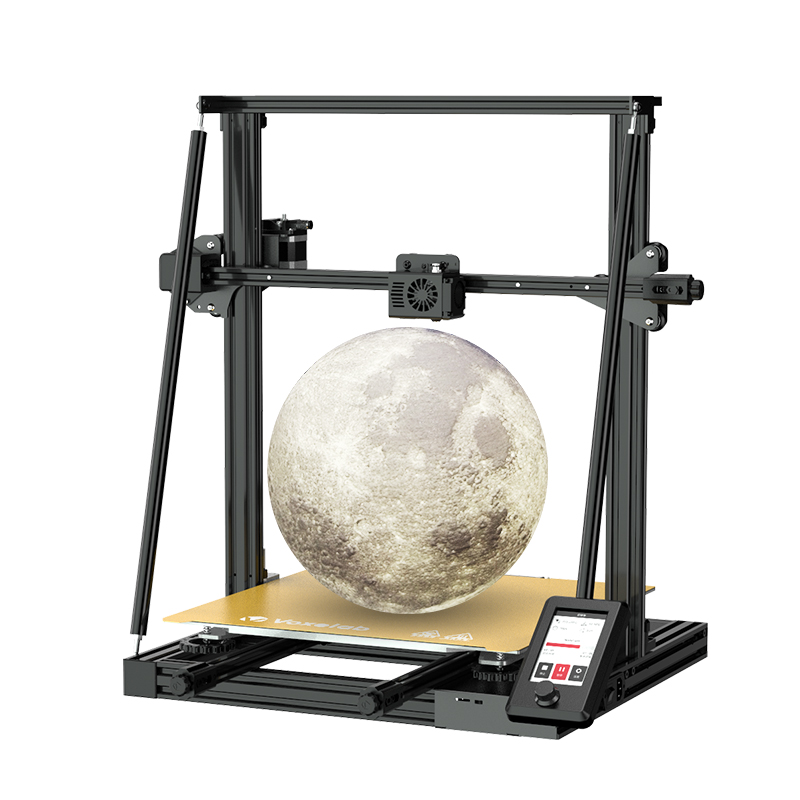

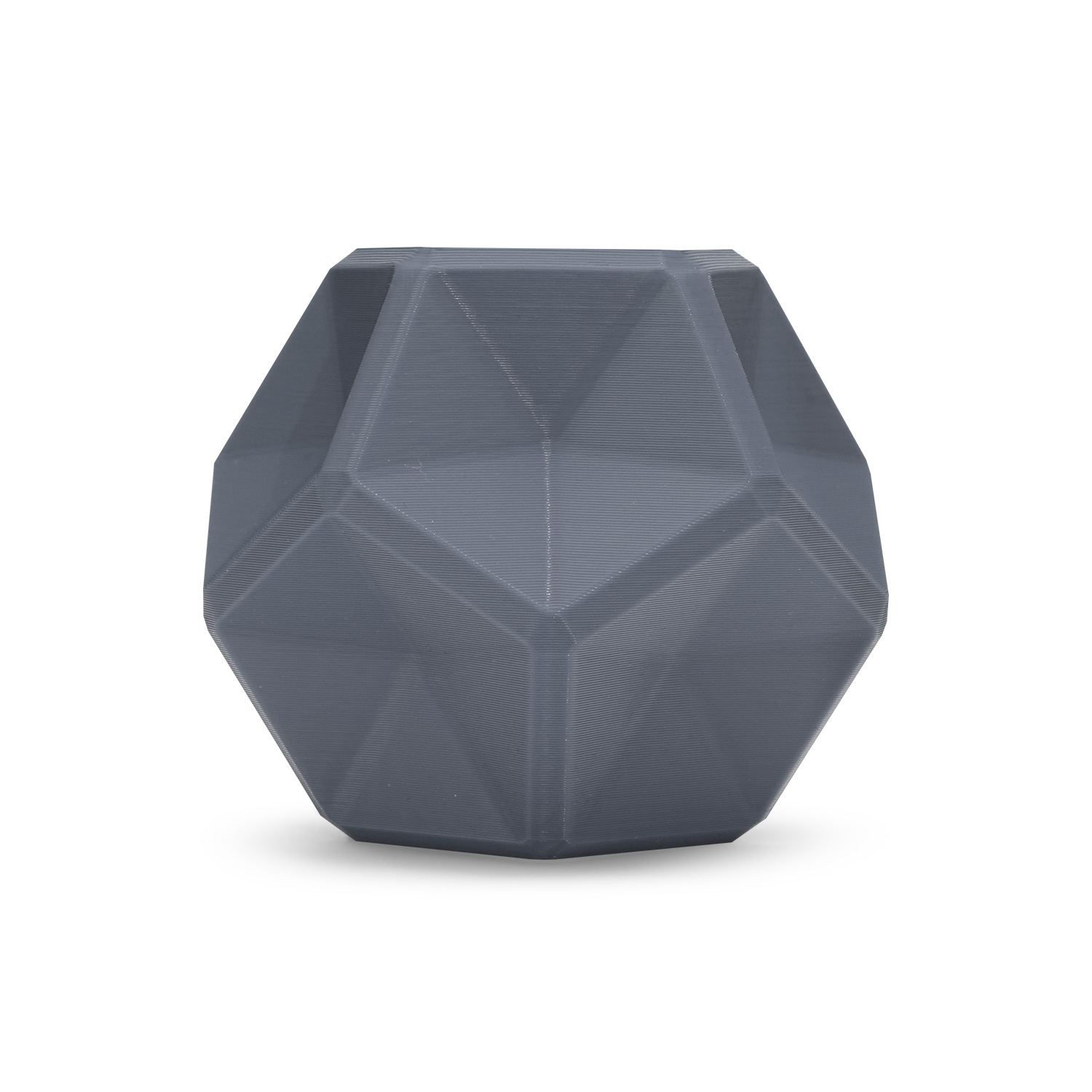

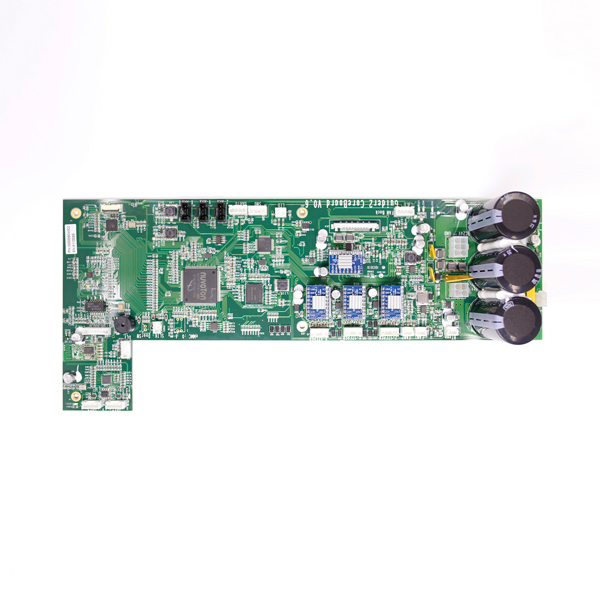

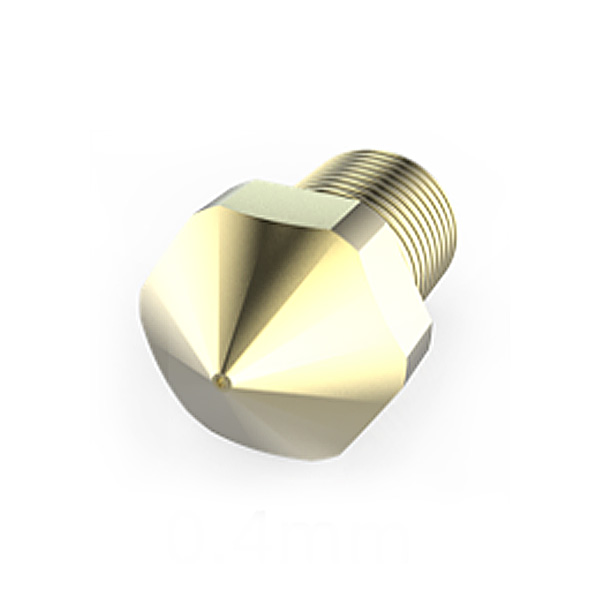

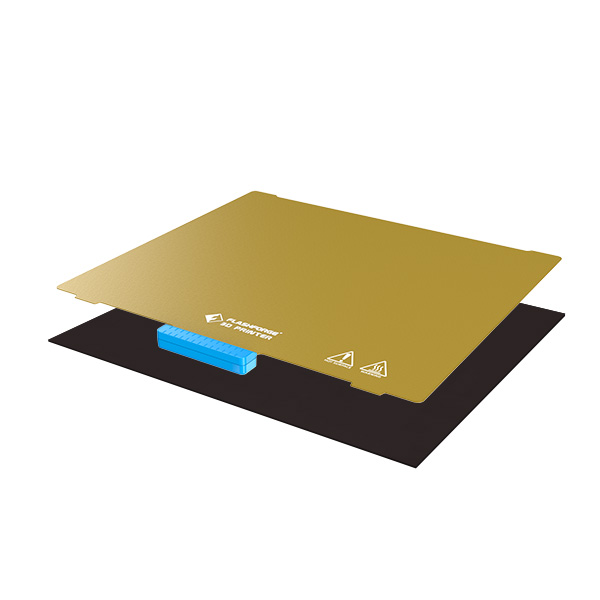

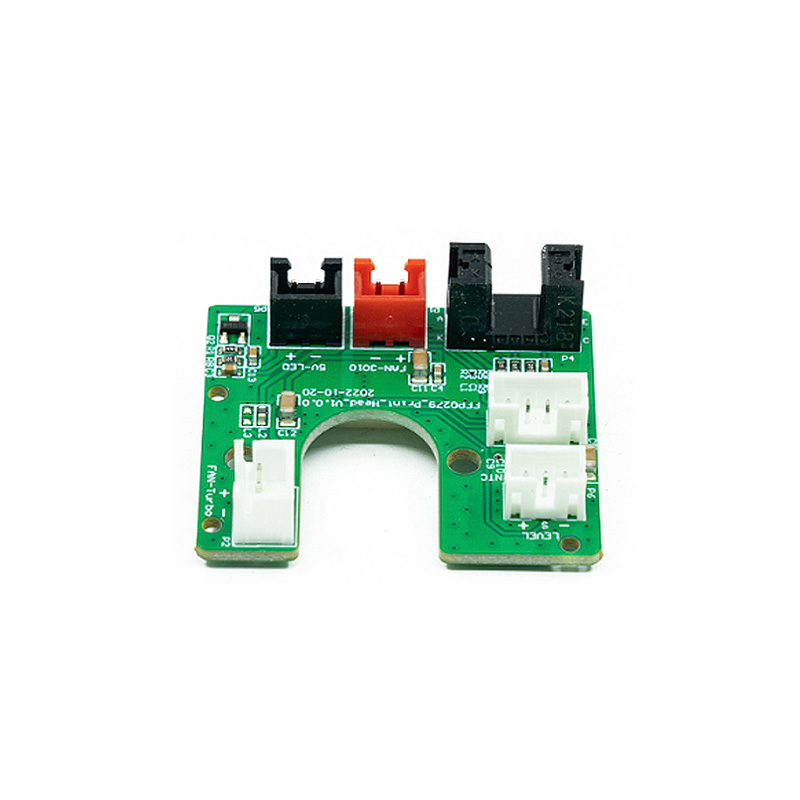

Incorrect Bed-leveling

Mistake #2: Improper Handling of Resin

Many people overlook the importance of proper handling of SLA 3D printer resin, which can lead to failed prints and even damage to the printer..

Common mistakes when handling resin:

- Underexposing or over-exposing it to sunlight

- Not properly sealing the bottle

- Leaving the bottle open for extended periods

The consequences of mishandling resin are failed prints, severe damage to the printer's parts and resin that is left unusable…so you need to be very keen when handling resin and here's how!

You can handle resin properly by these ways:

- Store in a cool, dark place

- Avoid exposure to direct sunlight or UV light

- Use gloves when handling to prevent skin irritation

- Properly seal the bottle after use to prevent contamination.

By following these tips, you can ensure that your resin is properly handled, leading to high-quality prints and a longer lifespan for your SLA 3D printer.

Here you can look at a case of David Gewirtz, a computer scientist who didn’t expose the resin properly in sunlight which led to the melting of the object after some time!

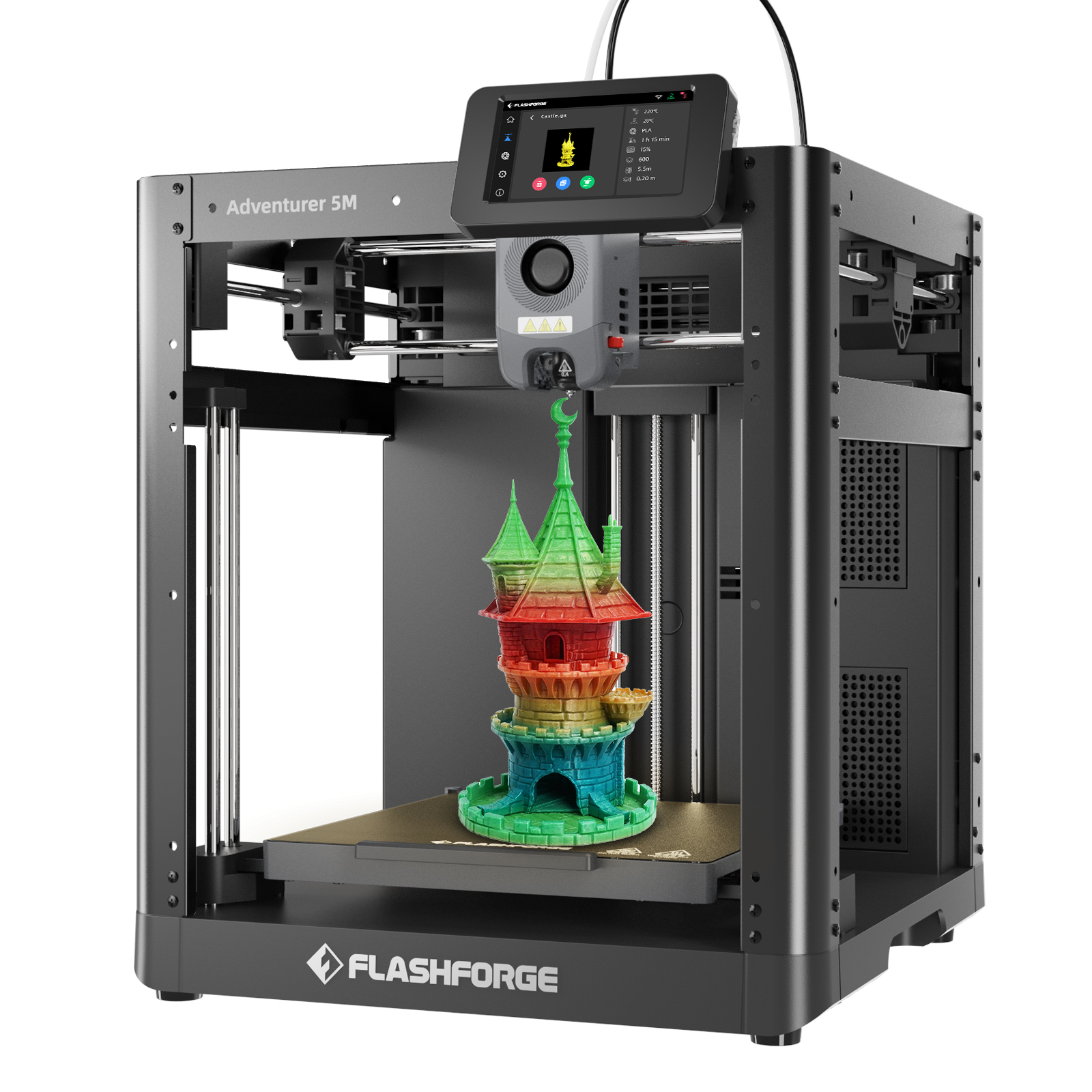

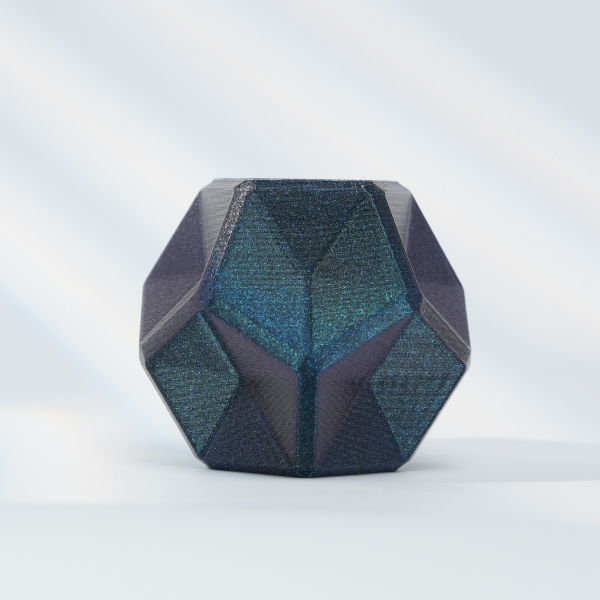

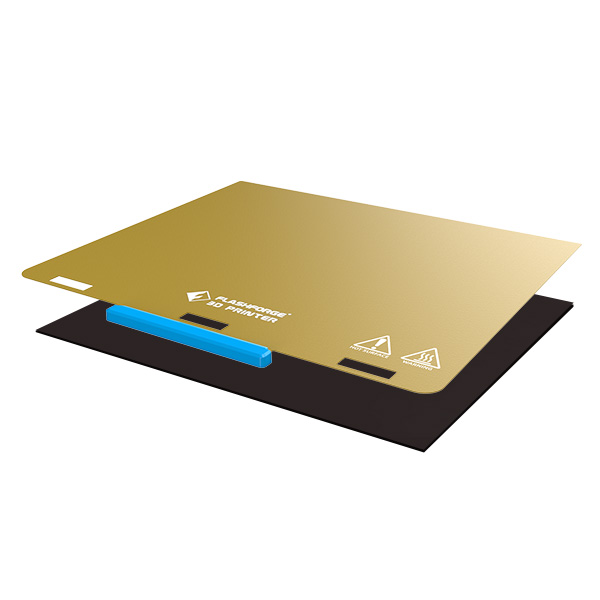

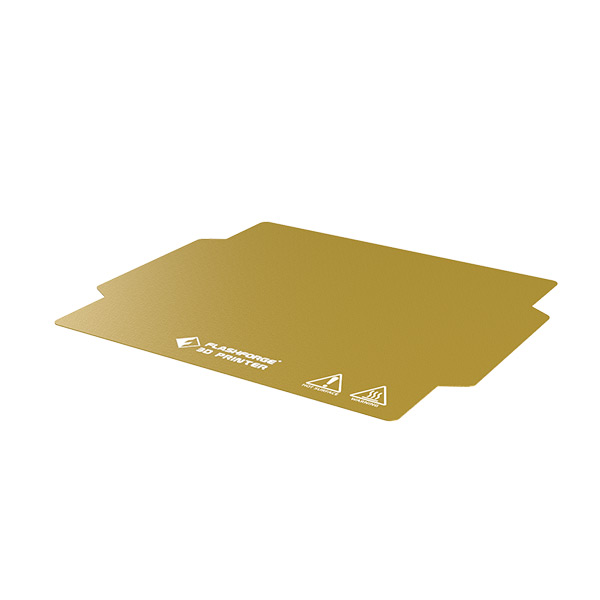

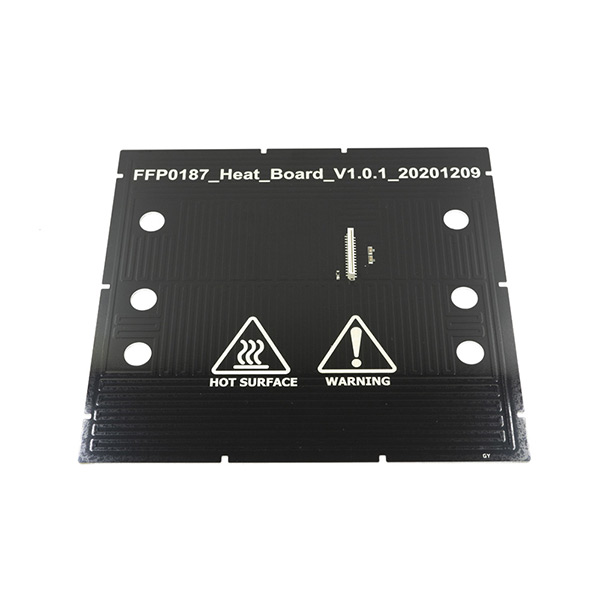

Failed 3D Resin prints due to mishandling.

Mistake #3: Inadequate Post-Processing

Post-processing is a crucial step while using SLA in 3D printing that involves removing support structures and cleaning the print. Inadequate post-processing can lead to print defects, such as rough surfaces or incomplete removal of support structures.Common mistakes people make during post-processing include:

- Not cleaning the print thoroughly

- Using the wrong tools for cleaning

- Failing to inspect the print for leftover support structures

These mistakes can result in prints that look rough or have unsightly support structures still attached.

To avoid these issues, it's important to use the right tools and techniques for post-processing. Some tips include:

- Use a soft-bristled brush and isopropyl alcohol to clean the print thoroughly

- Inspect the print carefully to ensure all support structures are removed and the surface is smooth

- Consider using additional post-processing techniques such as sanding or polishing to achieve a desired finish.

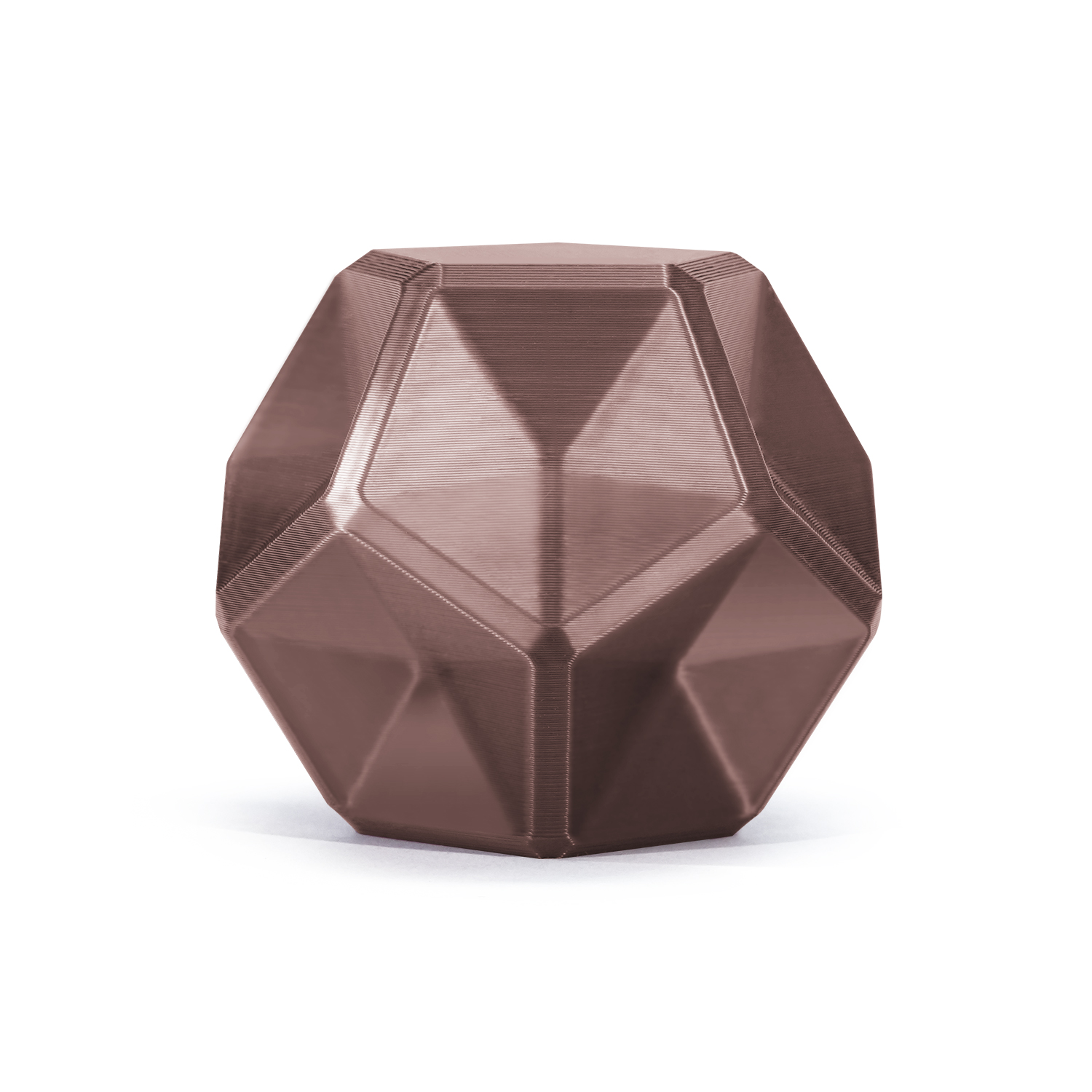

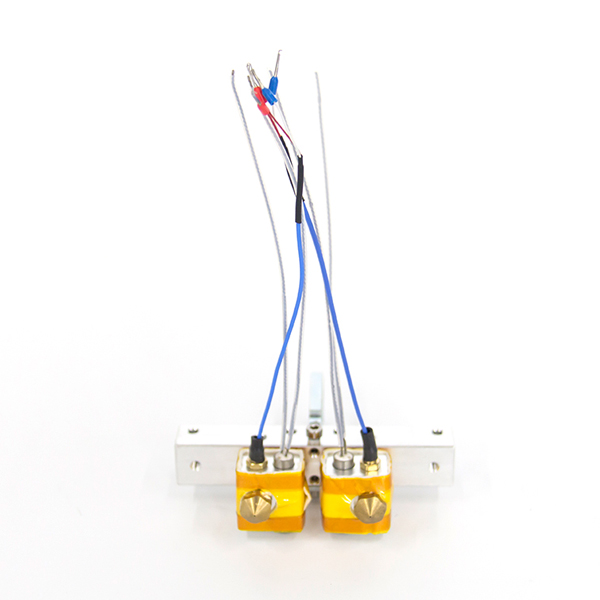

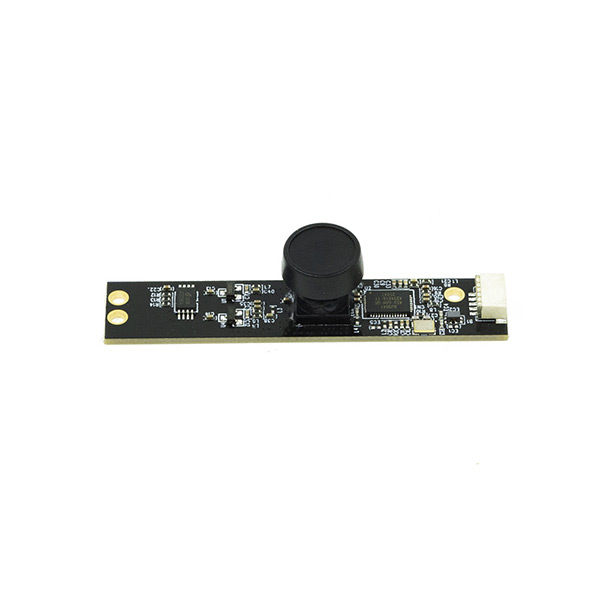

Post-Processing of 3D Print

Mistake #4: Insufficient Ventilation

Ventilation is also an essential factor to consider when using an SLA 3D printer. Without proper ventilation, fumes emitted during the printing process can accumulate and pose a health hazard to users. Common mistakes people make when it comes to ventilation in SLA 3D printing

- Not having proper ventilation or using the printer in an enclosed space

- Not wearing proper protective gear, such as a respirator

-

Ventilation is very important for sla 3D Printing as accumulation of resin fumes can be toxic and harmful to health, on the other hand, lack of ventilation can result in a buildup of resin fumes in the air, which can lead to health problems. So, be careful to properly ventilate in SLA 3D printing! Here's how:

- Ensure proper ventilation in the room where the printer is being used

- Use the printer in a well-ventilated area or install a ventilation system

- Wear proper protective gear, such as a respirator, when working with resin

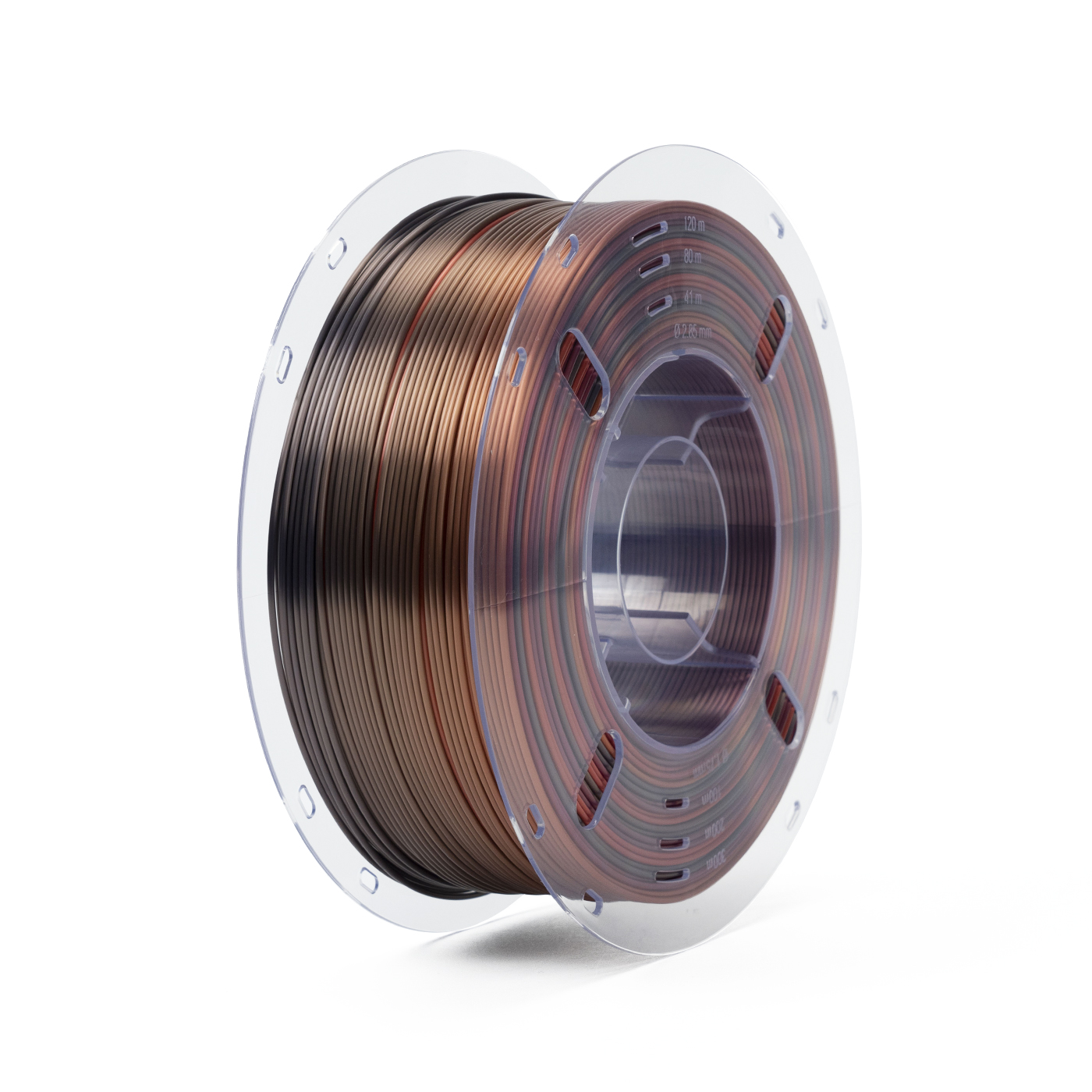

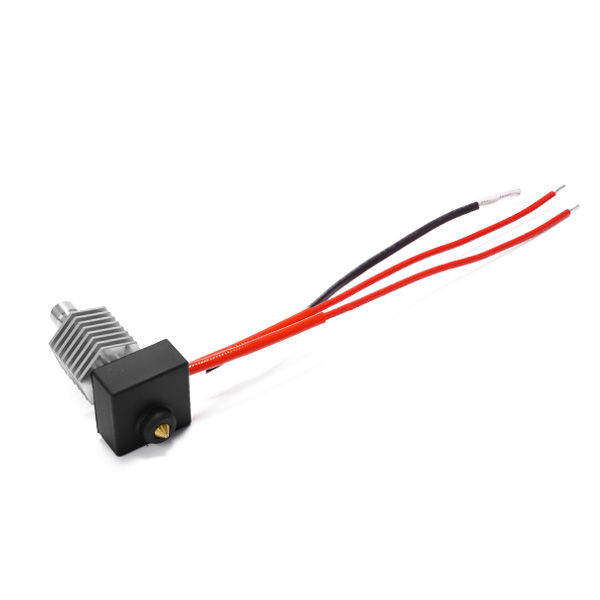

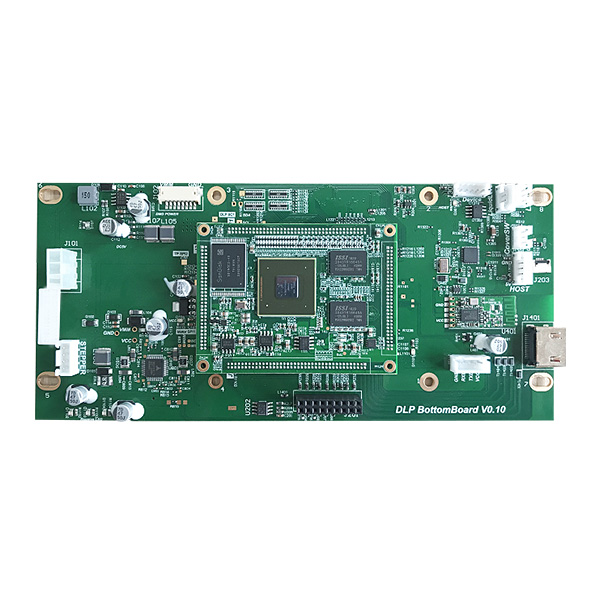

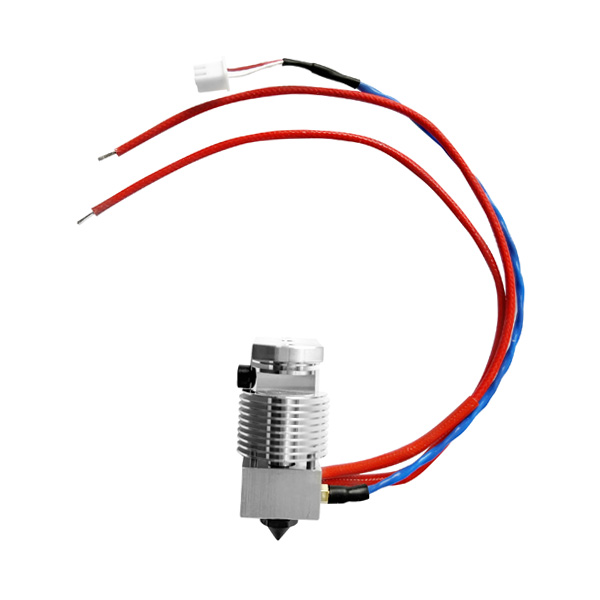

Install a Proper Ventilation system with the Printer

Case: A 3D Print enthusiast in US shares how toxic fumes had affected him alot during 3D Printing with resin, not only this, due to improper safety measures taken, a shard of resin also fell into one of his colleagues eyes, which had to be quickly washed off with soap and water. So, he mentions how he feels it's very necessary to wear gloves and goggles and install a proper ventilation system for safe printing!

Mistake #5: Not Maintaining the Printer

Regular maintenance is a must thing for the proper functioning and longevity of your SLA 3D printer. This includes

- cleaning the build platform

- replacing the resin tank

- checking for any worn-out parts.

People sometimes common mistakes with printer maintenance such as

- not cleaning the printer after every use

- ignoring warning signs of worn-out parts

- not following the manufacturer's recommended maintenance schedule.

And this can be a con for you. So, ensure proper maintenance by creating a schedule to ensure all necessary maintenance tasks are completed regularly. It's also important to follow the manufacturer's recommendations for replacement parts and to regularly check for any signs of wear or damage.

Final thoughts.

In conclusion, SLA 3D printing can produce high-quality, precise prints, but only if you give careful attention to detail and proper handling and avoid common mistakes. This can help ensure successful and consistent results.

By following best practices and taking the time to properly maintain and operate the printer, you can achieve optimal print quality and reduce waste and costs. In this way, your SLA printing can be free from running any errands!

Looking to unleash your creativity with 3D printing but don't know where to start? Say hello to Flashforge Shop! Our expert team will guide you through the world of 3D printing and help you find the 3D printer that fits your needs and budget. With unbeatable prices and top-notch service, we're your one-stop-shop for all things 3D printing.