Are you tired of 3D prints that come out weak and fragile? Do you want to know the secret to creating prints with exceptional strength? Look no further than adjusting the layer height!

In this article, we'll explore the importance of layer height in 3D printing and how it can impact the strength of your prints. We'll cover the basics of layer height and provide a brief overview of the article, so you'll know exactly what to expect. So why should you read on? Because with the right 3D Printer layer height, you can create 3D prints that are not only strong but also aesthetically pleasing. Let's dive in!

What is Layer Height?

Welcome to the world of 3D printing, where layer height is a critical aspect that determines the quality of your prints. Layer height refers to the thickness of each layer that a 3D printer deposits to create a 3D model. A smaller layer height means thinner layers, resulting in a more detailed and high-resolution print, while a larger layer height will result in a quicker print but with less detail.

Understanding the importance of layer height is crucial for achieving optimal print quality. A well-calibrated layer height can improve the accuracy, strength, and surface finish of your prints, while a poorly set layer height can lead to issues such as layer shifting, rough surfaces, and weak parts.

In 3D printing, layer height is set using slicing software, which translates the 3D model into a series of 2D layers, each with a defined height. The software then sends this information to the printer, which deposits each layer until the final model is complete.

By setting the layer height correctly, you can achieve a balance between print quality and print time.

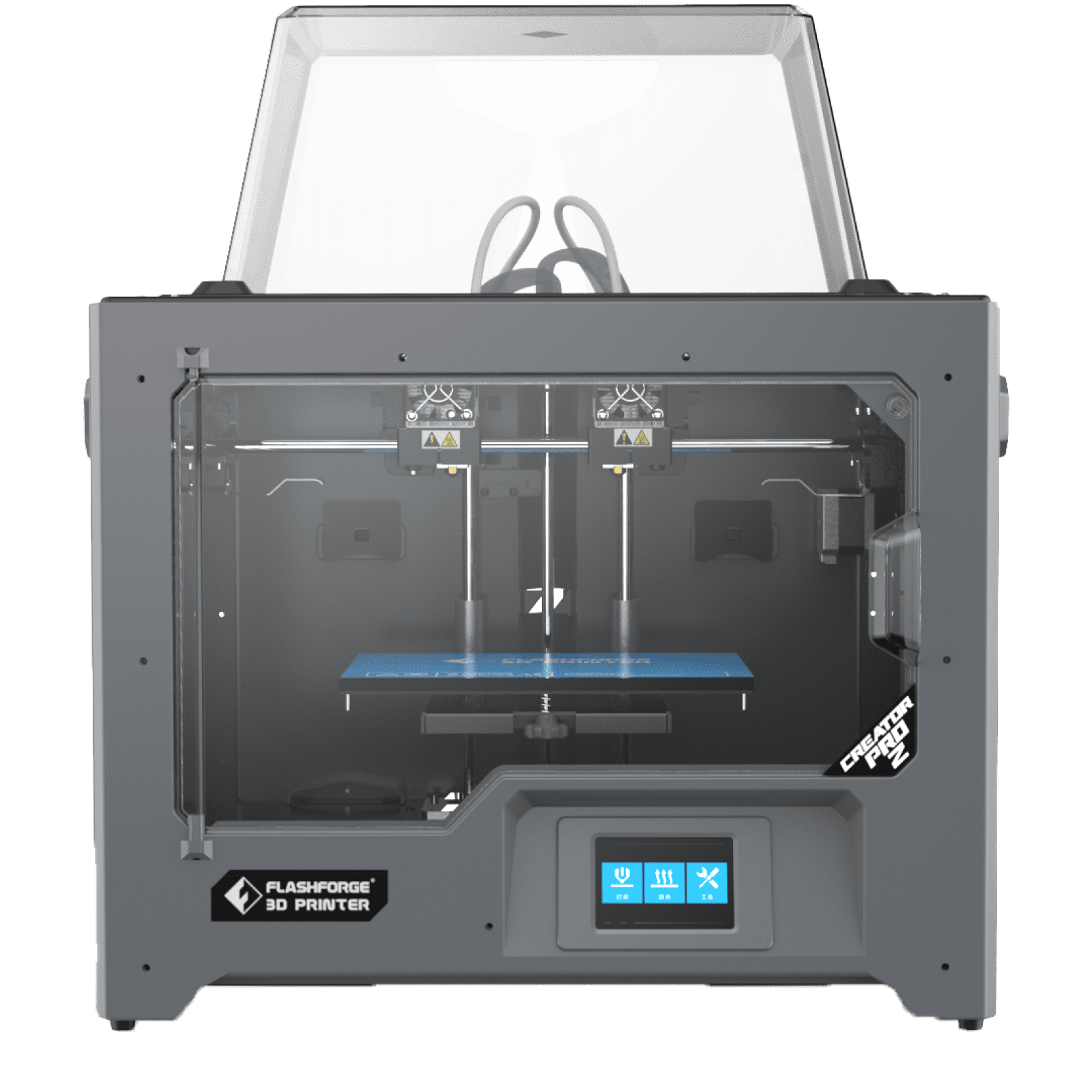

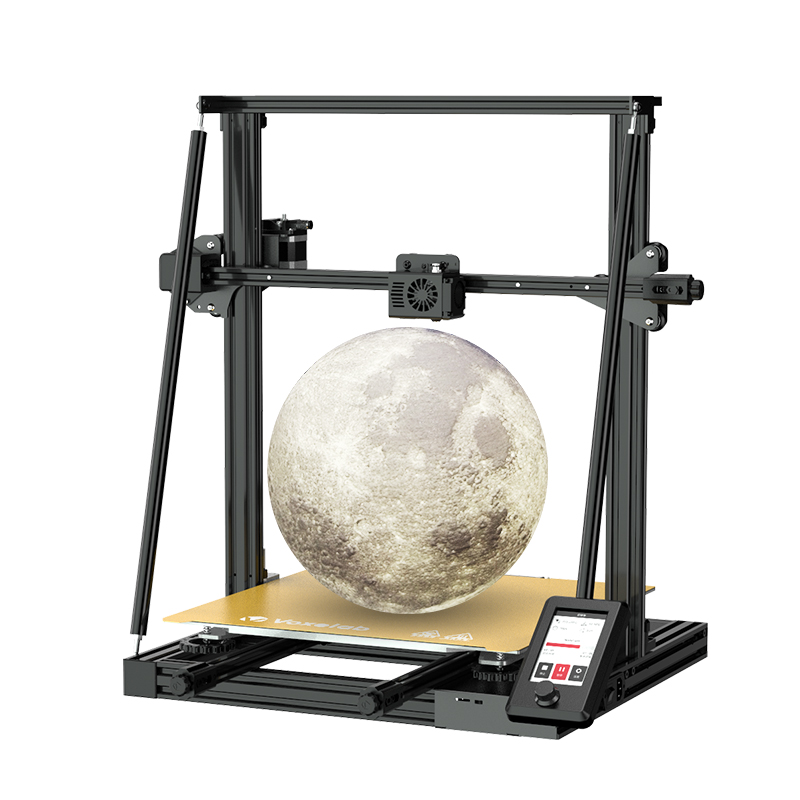

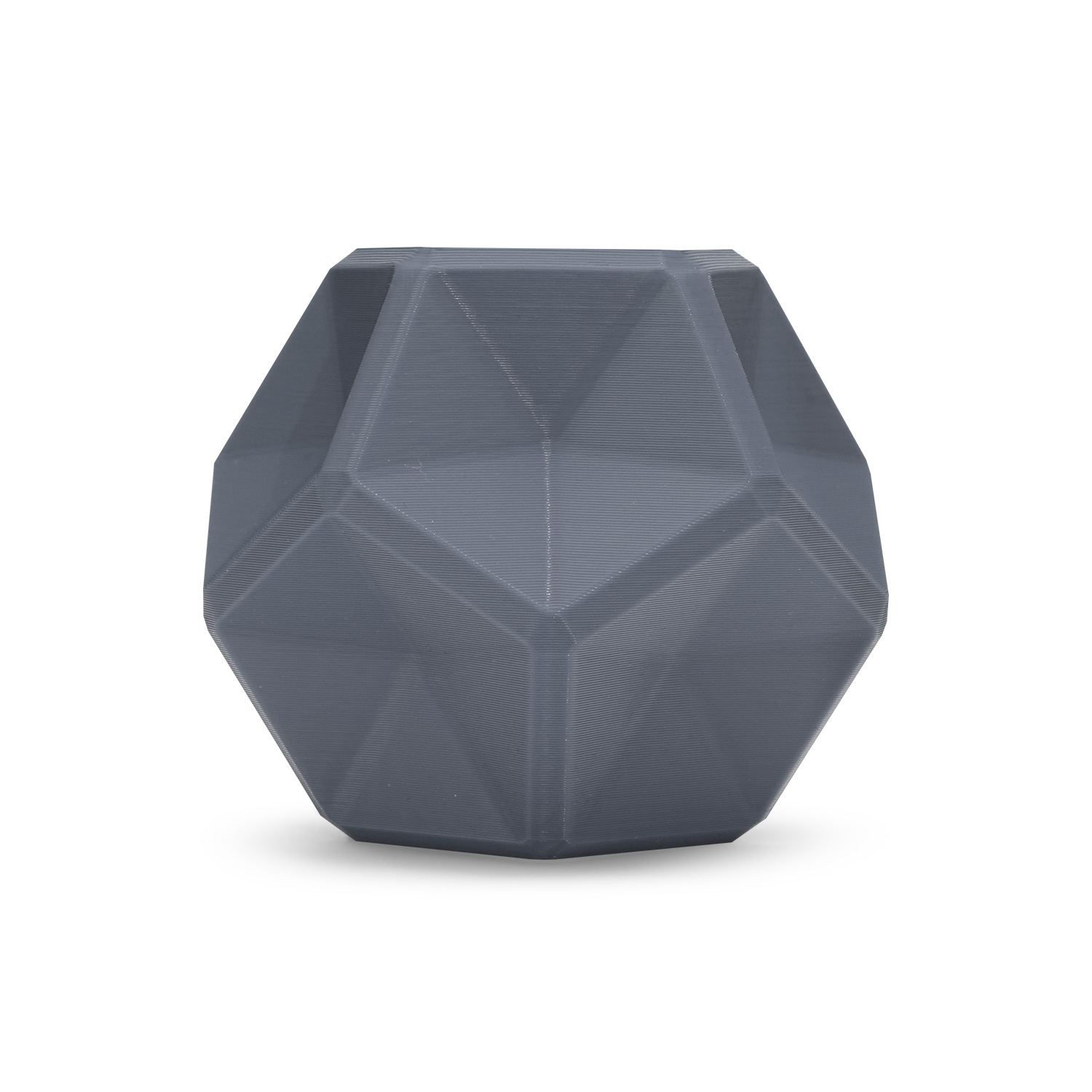

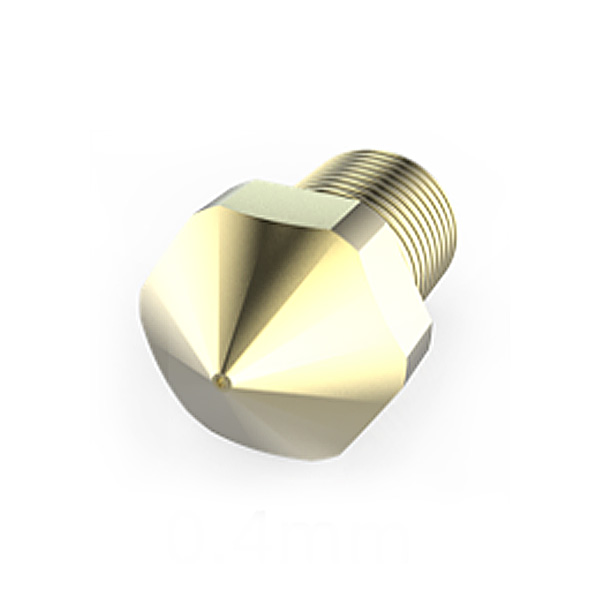

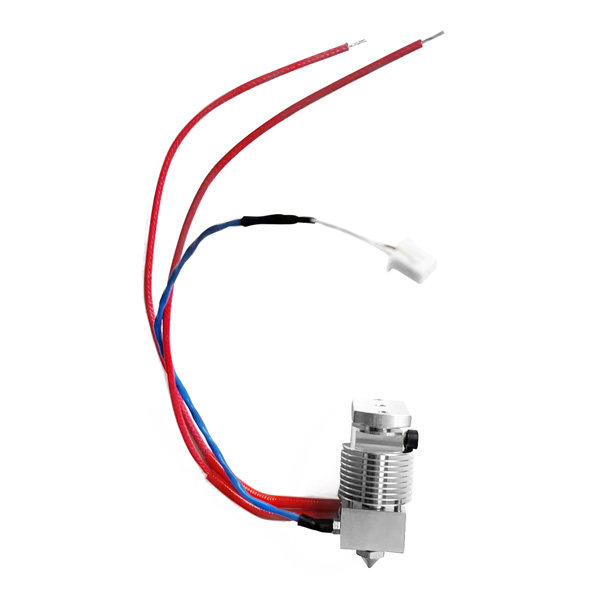

Object 3D Printed with layer height of 0.08mm with Flashforge Finder.

How layer height affects print strength

When comparing prints with different layer heights, it's easy to see that thinner layers generally result in stronger prints. This is because the thinner layers allow for more contact points between each layer, resulting in a stronger bond. Prints with thicker layers, on the other hand, have fewer contact points between each layer, which can lead to weaker prints.

You might be thinking about what is a good layer height for 3D Printing? The ideal layer height for strength depends on various factors such as the material being used, the printer's capabilities, and the intended use of the final print. As a general rule, a layer height of around 0.1mm is considered to be the sweet spot for achieving the optimal balance of print quality and strength. However, thinner layers can be used for applications that require maximum strength, while thicker layers may be suitable for prints that don't require high strength.

It's important to keep in mind that layer height is just one of the factors that affect print strength, and other factors such as infill density, print speed, and material properties should also be considered.

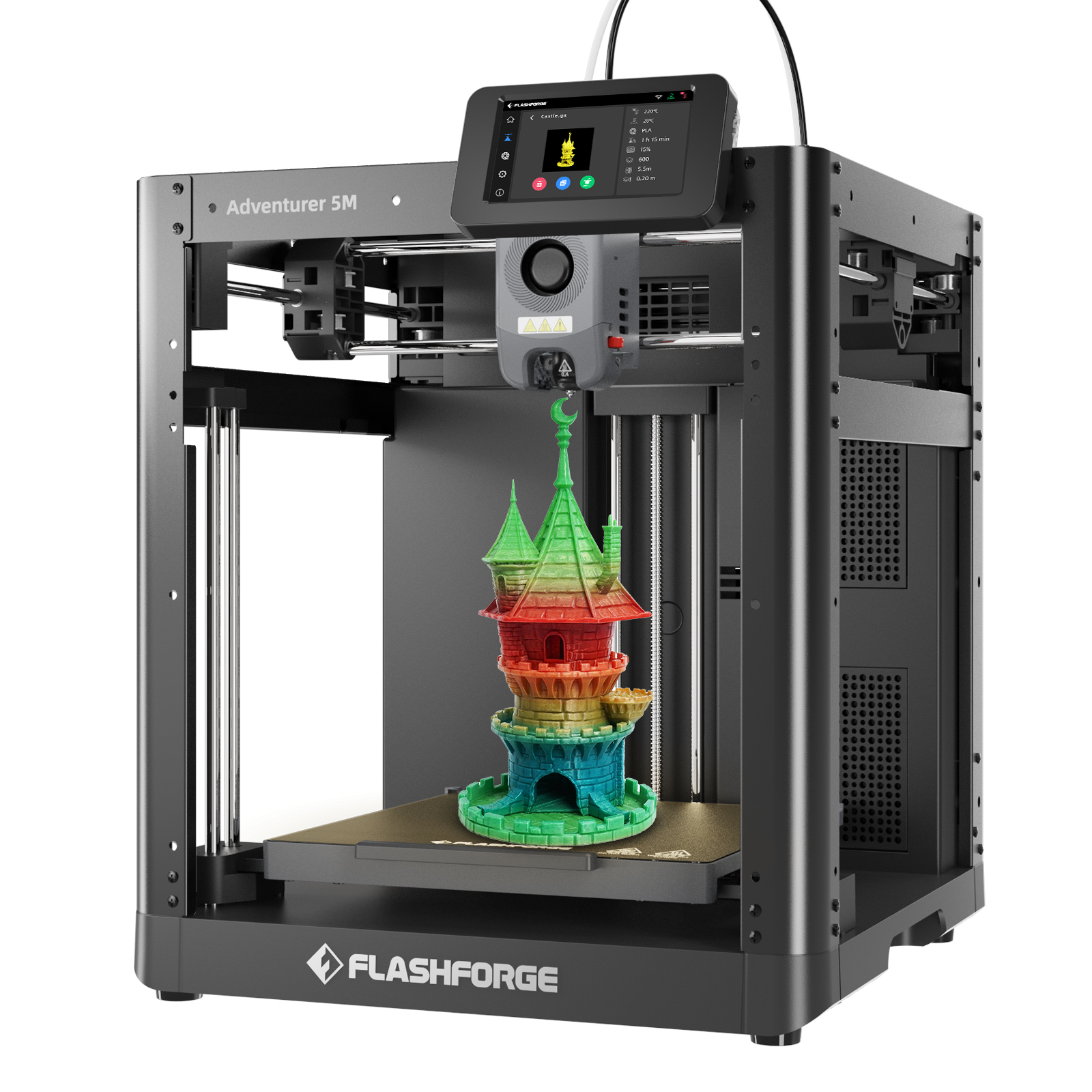

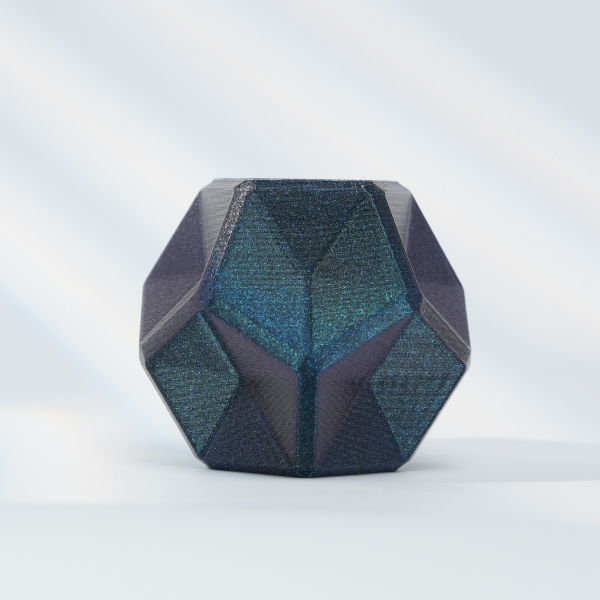

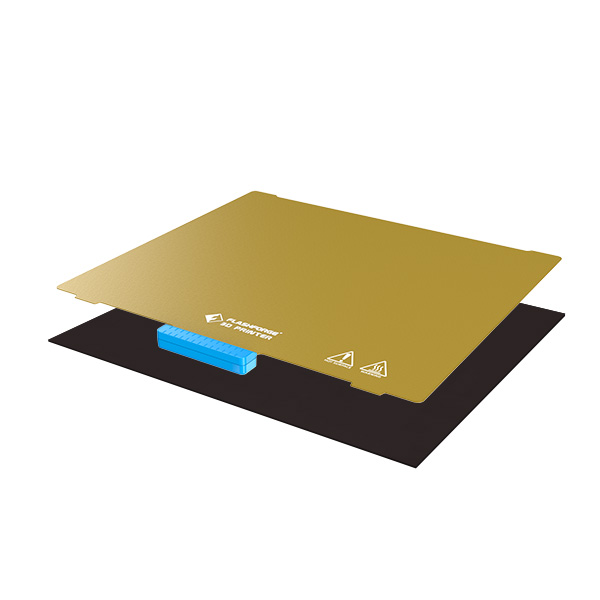

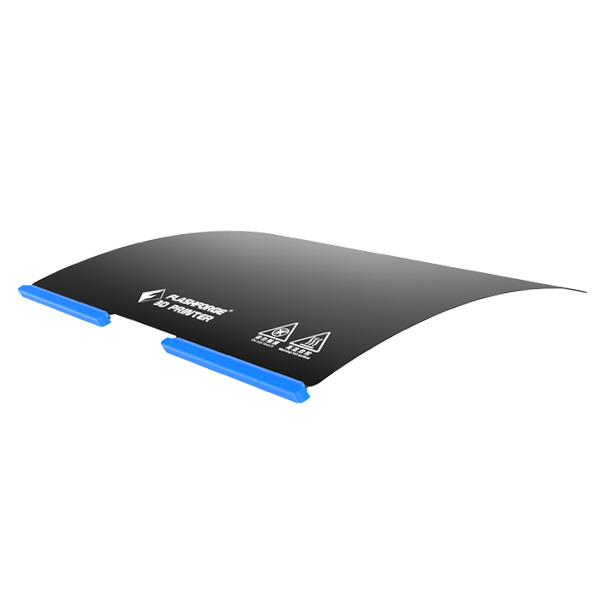

0.28 layer height on Adventurer 4 created a very strong 3D Print

Pro-tip: When trying to achieve the strongest possible prints, consider using a layer height that is approximately 50-75% of your nozzle diameter. This can help ensure that each layer properly adheres to the layer beneath it, creating a strong and sturdy print. Additionally, adjusting your layer height in small increments can help you find the ideal height for your specific project and materials.

Factors that affect Print Strength.

Print strength is an essential aspect of 3D printing, especially when it comes to creating functional or structural parts. The strength of a print is determined by several factors, let’s have a look;

- Layer height is one of the most critical factors affecting print strength. In general, thinner layers produce stronger prints because they increase the interlayer adhesion and reduce the potential for delamination. However, it's important to note that the print time will also increase with decreasing layer height.

- Infill density is another factor that plays a significant role in print strength. Higher infill densities result in stronger prints due to more material being used in the internal structure. However, it's essential to balance the infill density with the print time and material usage to ensure an efficient and cost-effective print.

- Print speed can also affect print strength, as faster printing speeds can lead to weaker prints due to reduced bonding between layers. Finding the optimal print speed for your specific printer and filament is crucial for achieving the desired print strength.

- Lastly, material properties such as the tensile strength, flexibility, and durability of the filament used can significantly impact print strength.

Choosing the right material for your specific project and ensuring that it's of high quality can help achieve a stronger print.

Case study: which layer 3D Printing creates the strongest 3D Print?

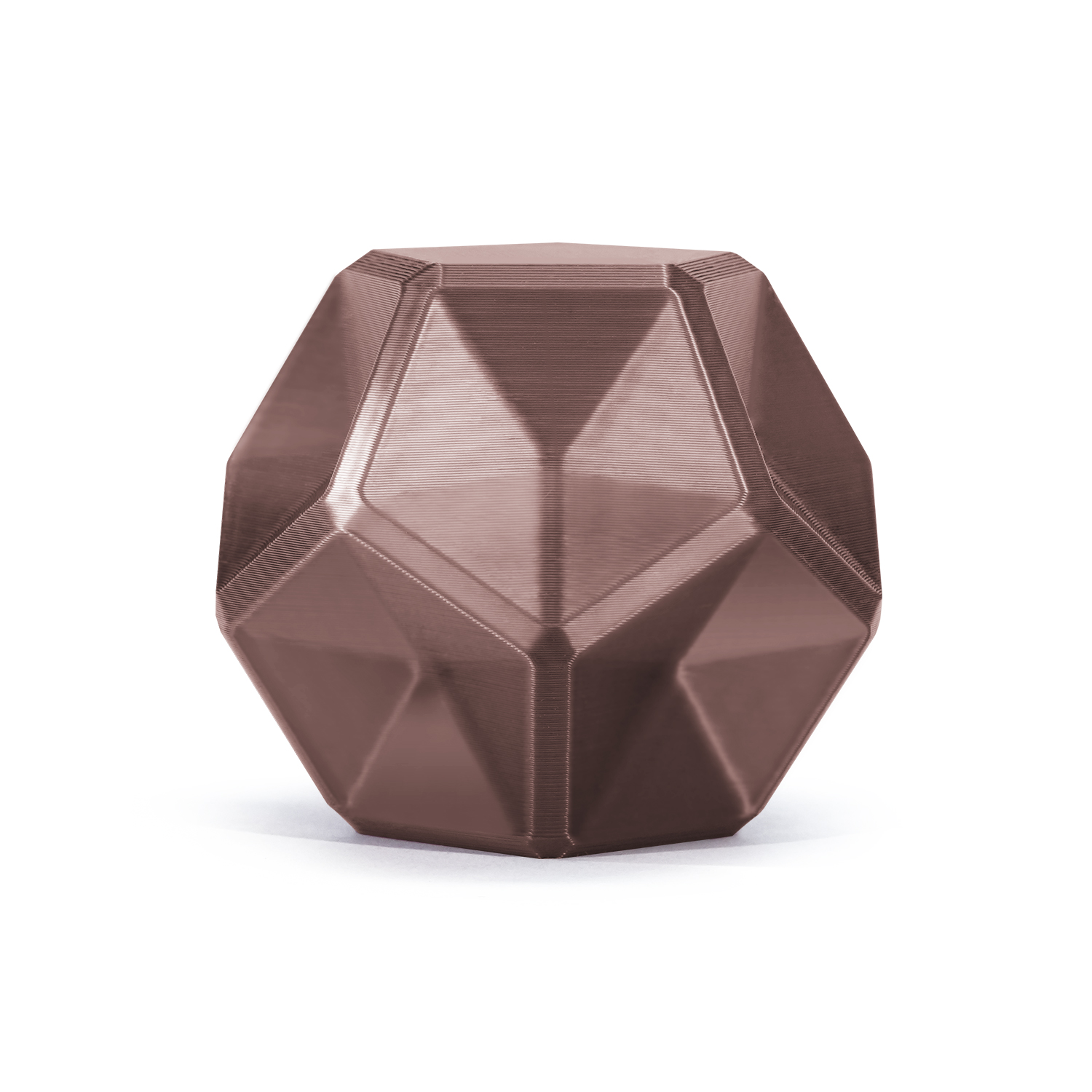

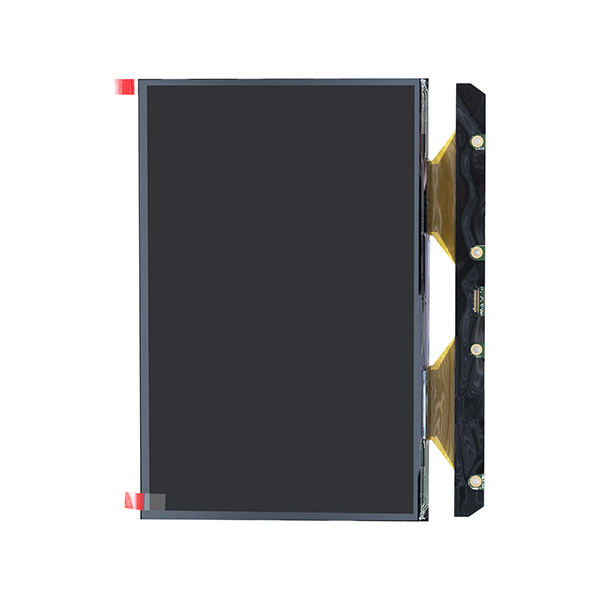

A 3D Printing enthusiast Stefan, carried out an experiment with his printer to see the impact of layer heights on his 3D Printed objects and here are the results as shown. He carried out a 3D Printer layer height comparison to see whether the thickness actually matters and printed several layer heights from 0.05mm to 0.40mm and measured their strength.

So, after experimenting he found that the thickness of each layer in a 3D print affects its strength. Prints made with thicker layers tend to be weaker, while those made with thinner layers are stronger and more accurate so that means that Higher layer heights generally result in weaker prints due to decreased inter-layer adhesion, while lower layer heights lead to stronger prints with better dimensional accuracy

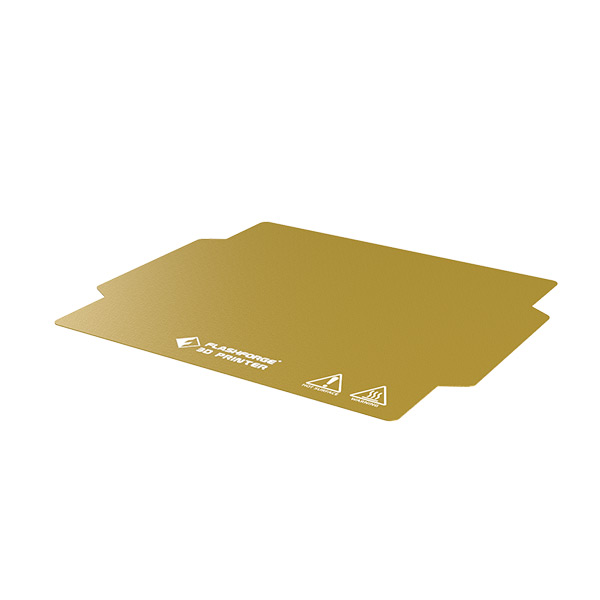

Different layer heights produced different qualities of 3D Print.

Tips for achieving stronger prints

If you're looking to achieve strong prints, there are a few tips and tricks that can help you get there.

- Firstly, choosing the right 3D printer layer height is crucial. As we discussed earlier, layer height has a significant impact on print strength. It's important to find the sweet spot between a low layer height for high detail and a high layer height for added strength.

- Secondly, adjusting other factors such as infill density and print speed can also contribute to stronger prints. Increasing the infill density will provide more support and stability to the print, while slowing down the print speed can reduce the risk of layer separation and improve adhesion.

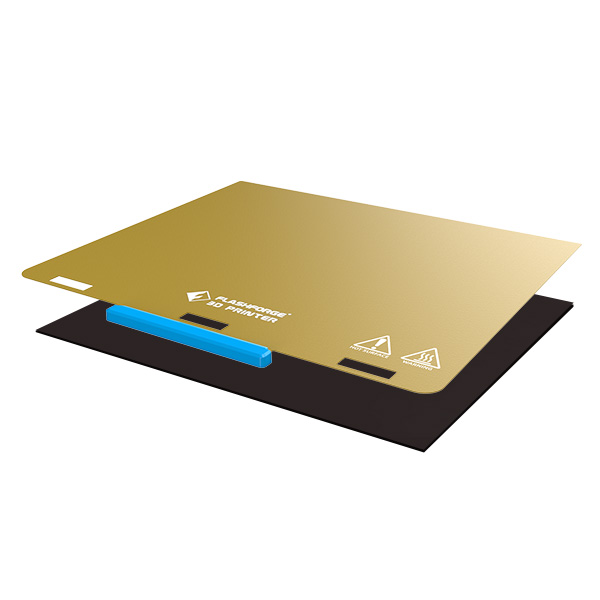

- Finally, it's important to follow best practices for optimizing print settings, such as ensuring the bed is level, using high-quality filament, and properly calibrating the printer. These small adjustments can make a big difference in the strength and overall quality of your prints

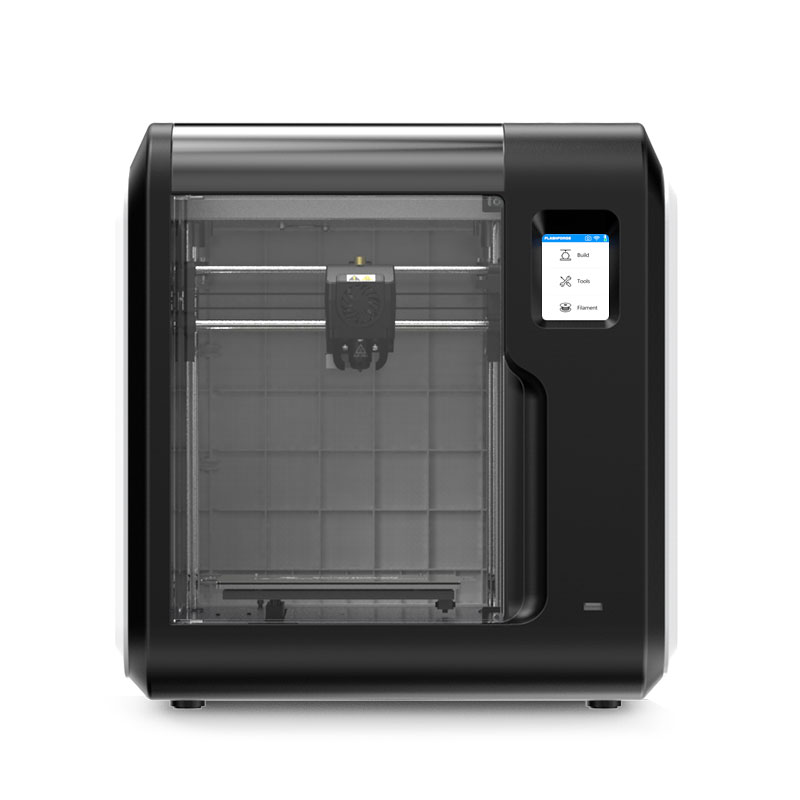

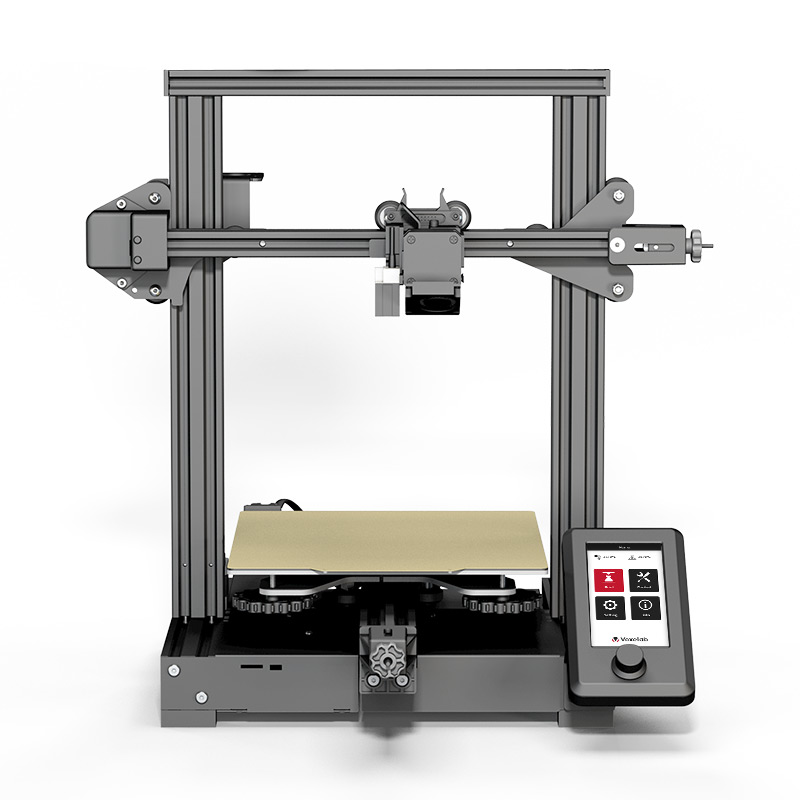

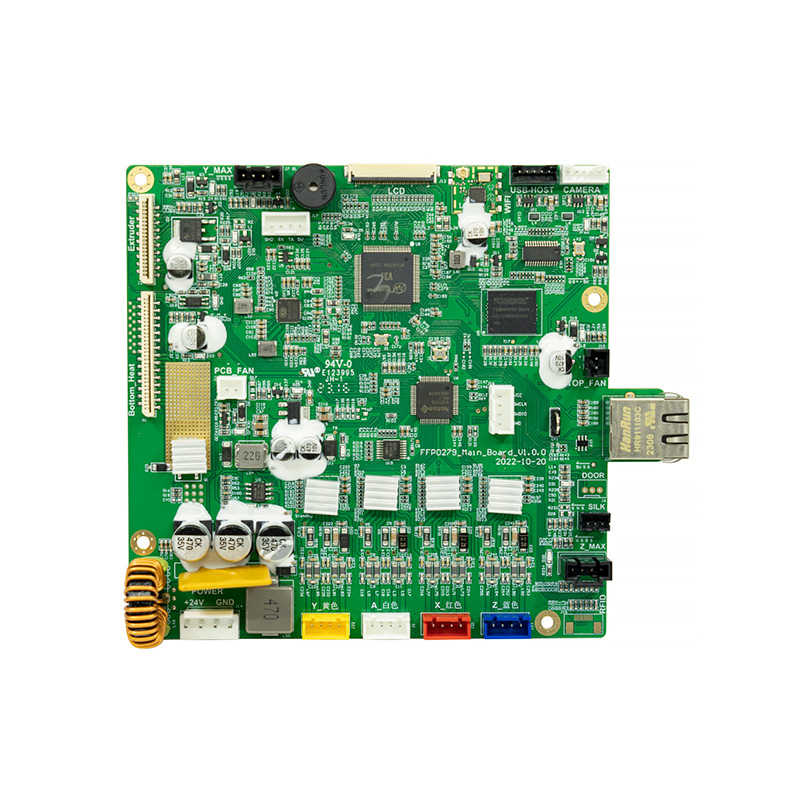

Looking to unleash your creativity with 3D printing but don't know where to start? Say hello to Flashforge Shop! Our expert team will guide you through the world of 3D printing and help you find the 3D printer that fits your needs and budget. With unbeatable prices and top-notch service, we're your one-stop-shop for all things 3D printing.