In the realm of 3D printing, making the right choice can often feel like navigating through a maze. With an array of models sporting diverse features, specifications, and physical dimensions, it's easy to get overwhelmed. However, understanding the variations and similarities among different models can simplify the decision-making process. Here in this article, we shine a spotlight on three models of 3Dprinters from Flashforge Adventurer 3 series: the Adventurer 3, the Adventurer 3 Pro, and the Adventurer 3 Pro 2.

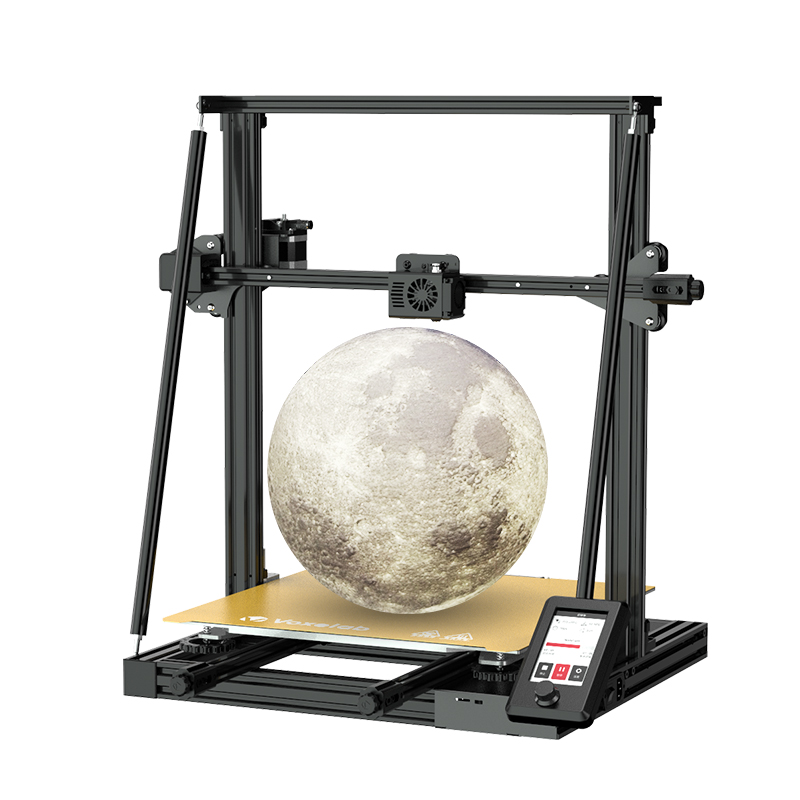

▲Adventurer 3(Left); Adventurer 3 Pro (Middle); Adventurer 3 Pro 2(Right)

Common Grounds

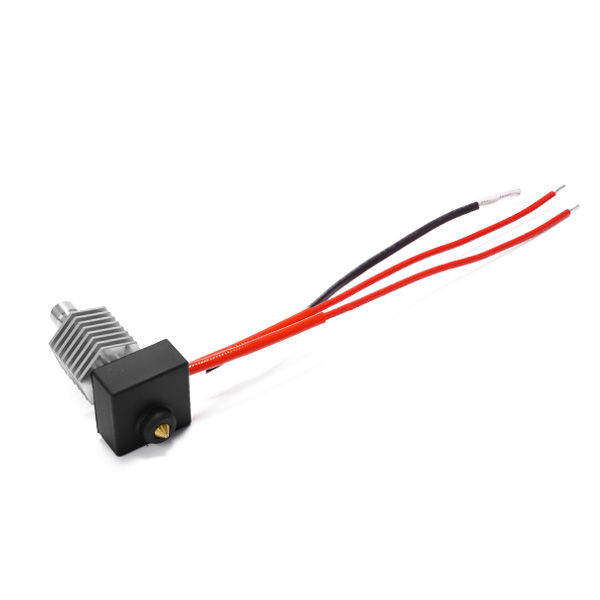

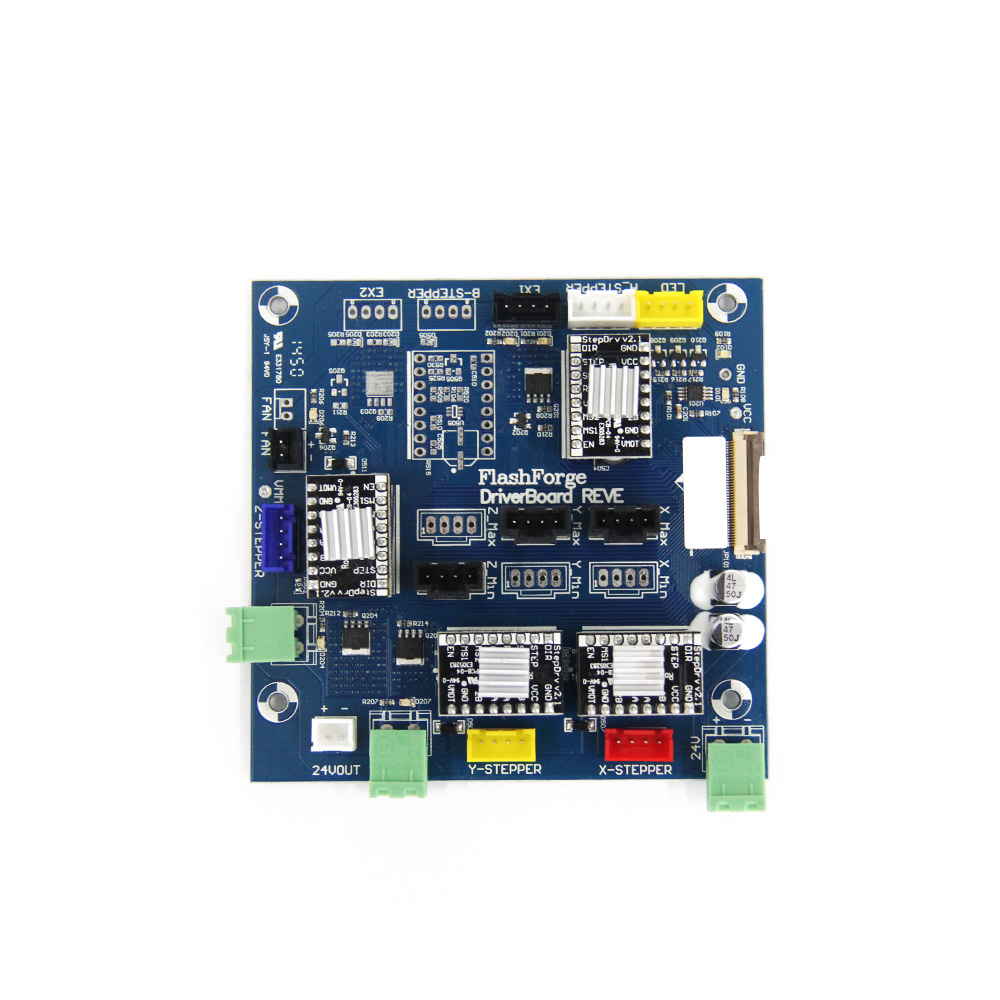

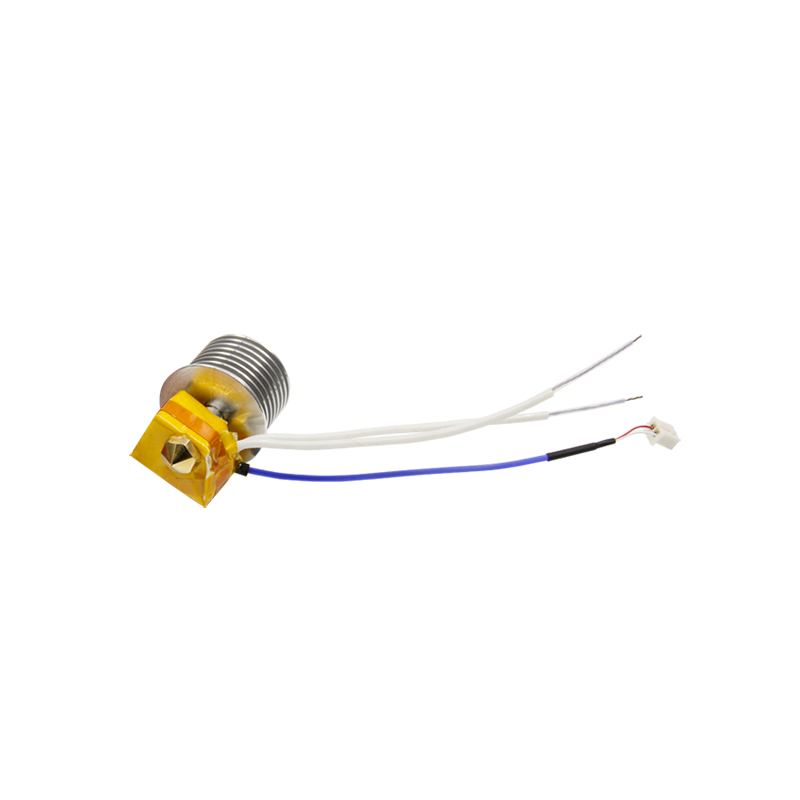

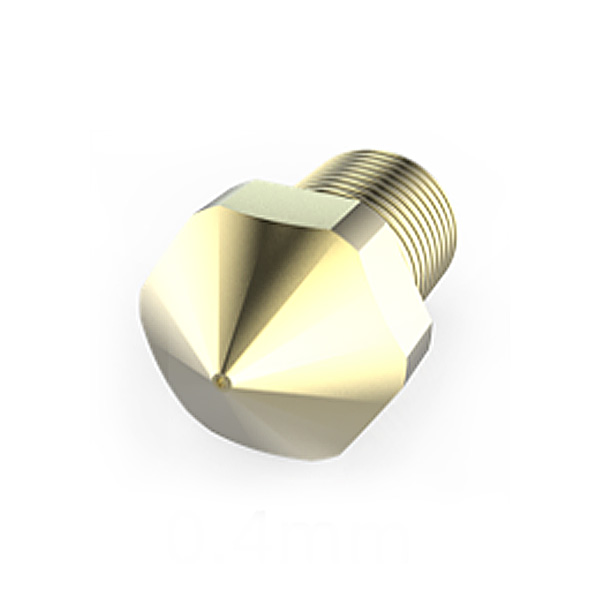

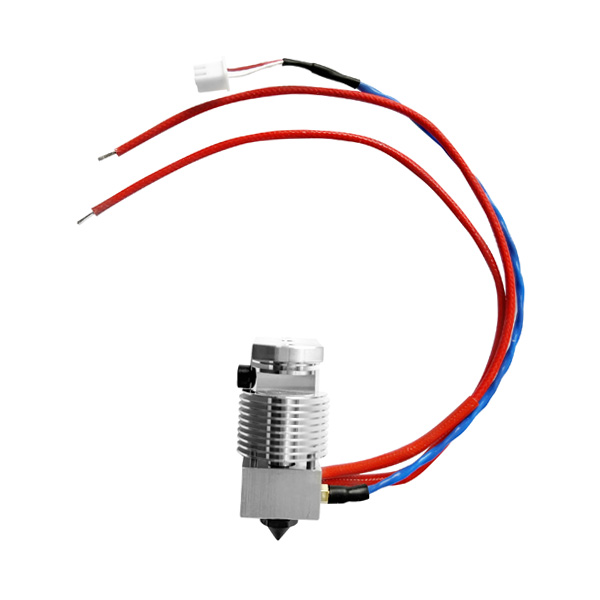

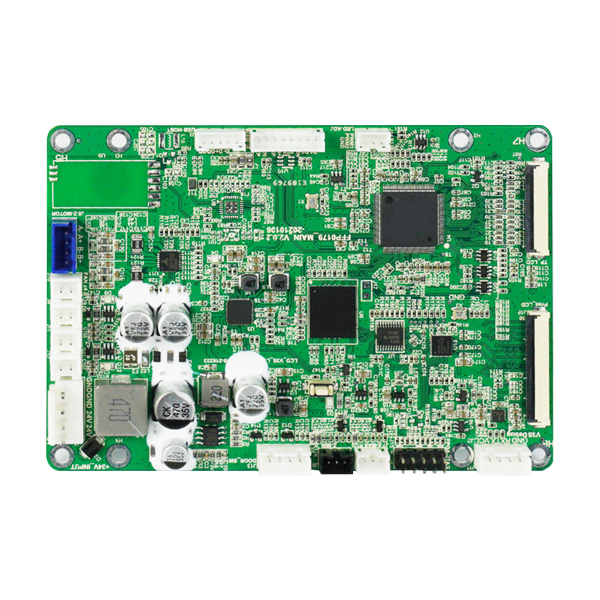

At the outset, the Adventurer 3 series shares several common attributes that ensure consistent, reliable, and high-quality 3D printing. All three models boast a single extruder, maintain a printing precision of ±0.2 mm, and have a layer thickness ranging from 0.1 to 0.4 mm. They accommodate a build size of 150 x 150 x 150 mm with a nozzle diameter of 0.4 mm. Additionally, the physical dimensions of each device and the packaging size remain identical across all models, simplifying logistics. Moreover, all three 3D printers achieve the same highest extruder temperature of 240℃, extending to 265℃ which allows for handling a wide variety of materials.

All Flashforge Adventurer 3 series 3D printers are consumer-level and cost-efficient. They share the same group of users.

For Beginners and Hobbyists

The Adventurer 3 series is user-friendly and easy to set up, making it ideal for individuals new to 3D printing. Its compact size and quiet operation are suitable for home use, allowing hobbyists to explore their creativity and bring their ideas to life.

For Education and Classroom Settings

The Adventurer 3 printers are commonly used in educational institutions, such as schools, colleges, and makerspaces. Their ease of use, safety enclosed-chamber feature, and reliable performance make them suitable for introducing 3D printing to students and facilitating technology learning experiences.

For Makers to do Prototype Test

The Adventurer 3 series offers a cost-effective solution for rapid prototyping and design iterations. Its decent print quality and reasonable build volume make it suitable for makers in fields like product design, engineering, and architecture.

Delving into Differences

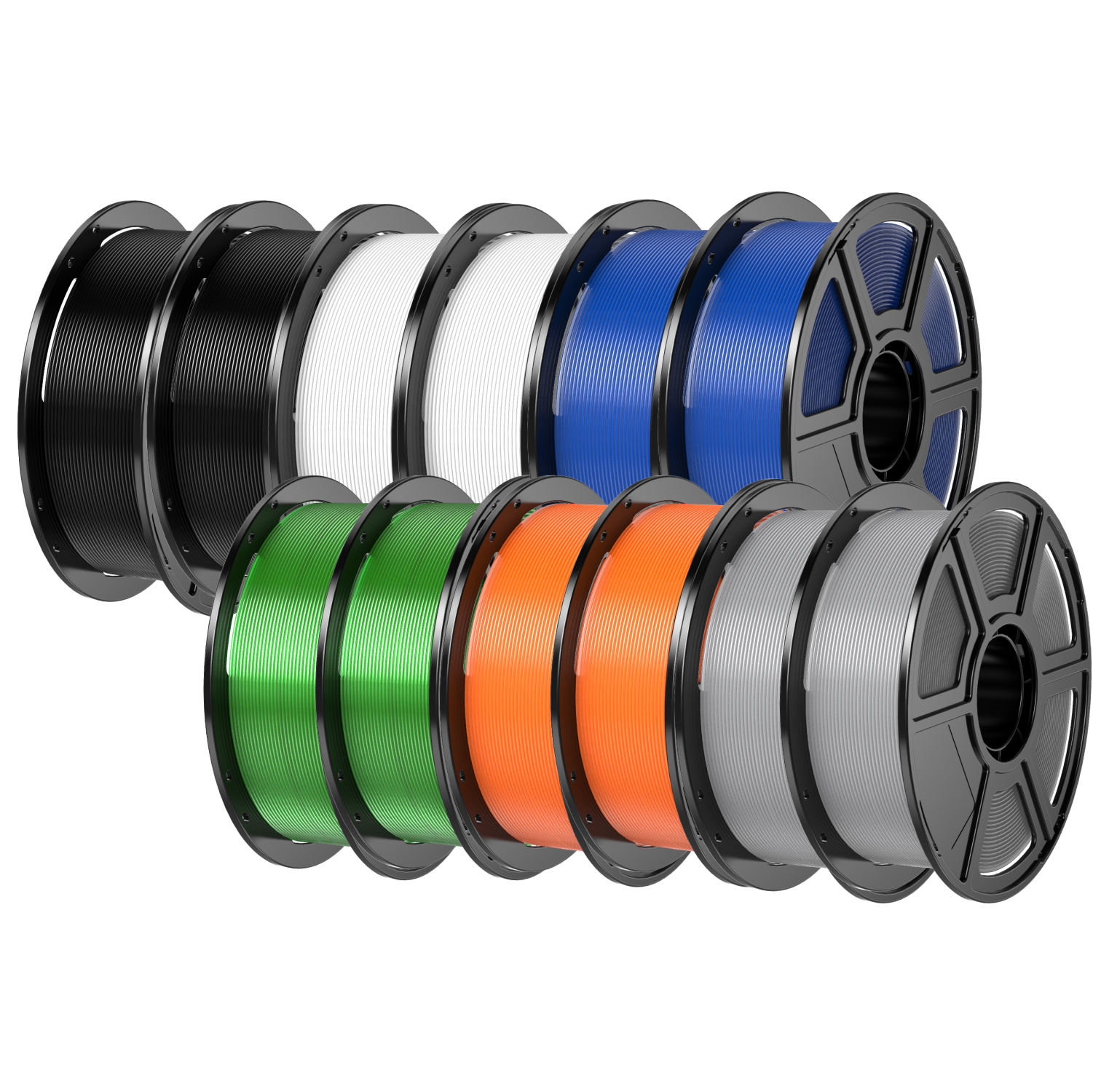

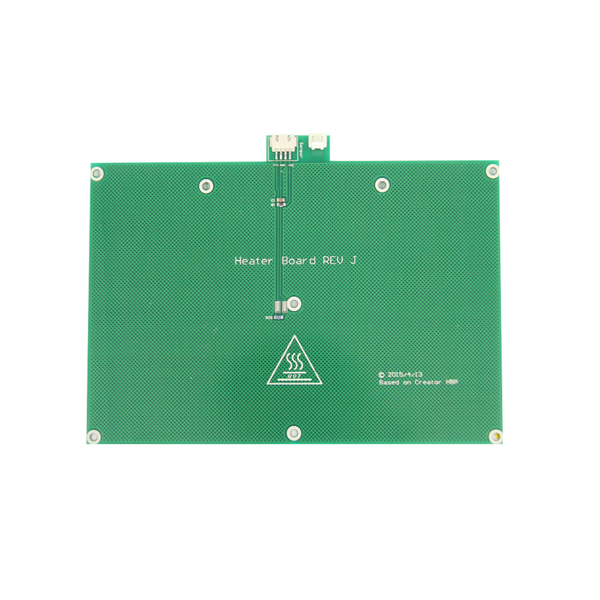

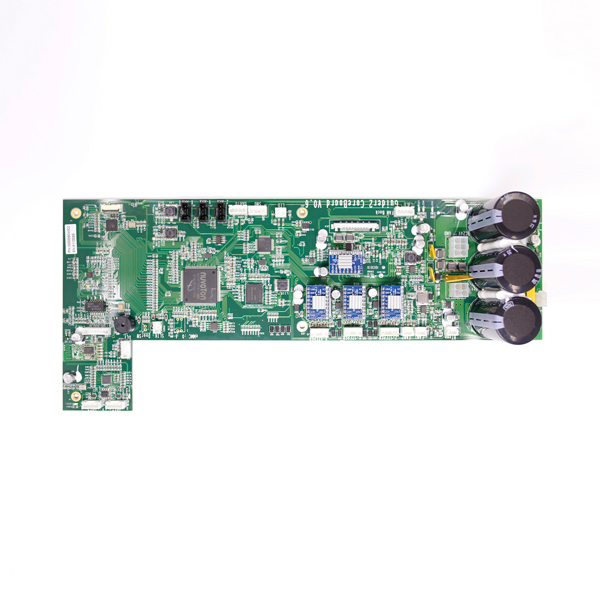

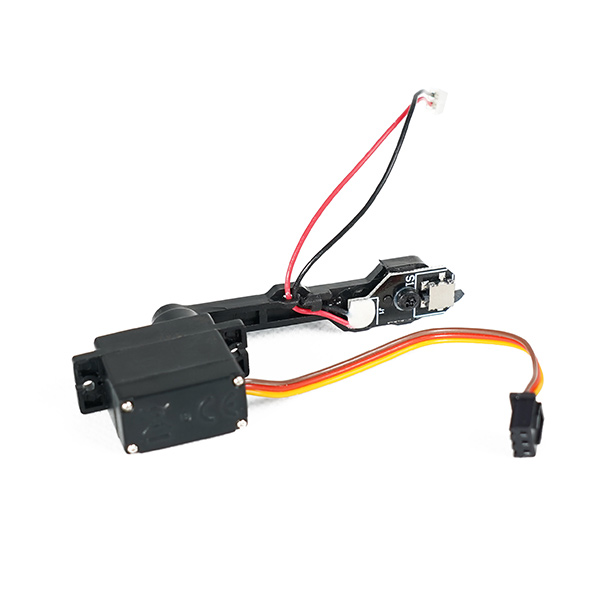

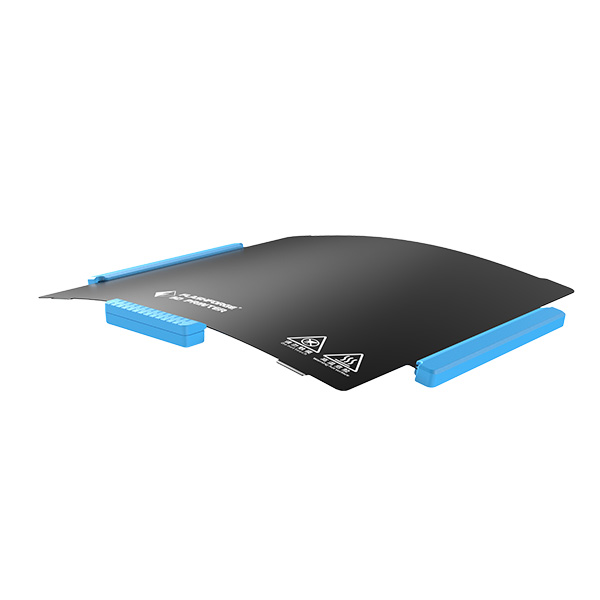

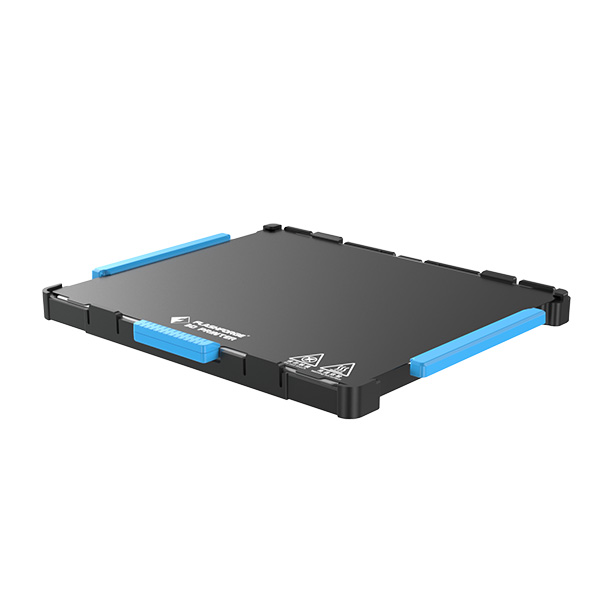

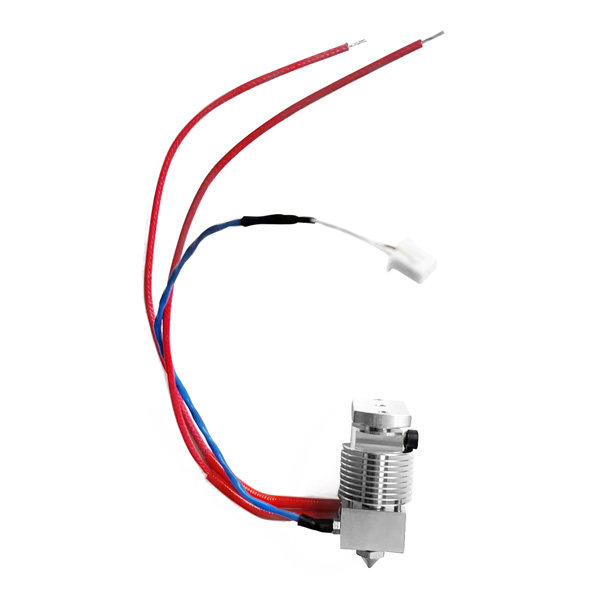

The Adventurer 3 is a great starting point for beginners. It's designed with a flexible build plate and offers a respectable printing speed acceleration of 10~100mm/s and 500mm/s2. This printer works with ABS and PLA filament types, making it an ideal choice for basic 3D printing requirements. The original build plate on the heating platform is a flexible sheet.

- Printing speed: 10~100mm/s; 500mm/s2

- Compatible with: PLA/ABS

- Build plate: flexible sheet

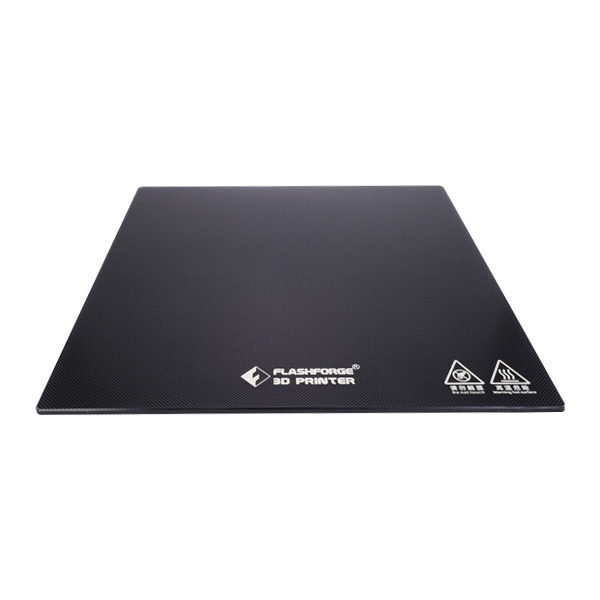

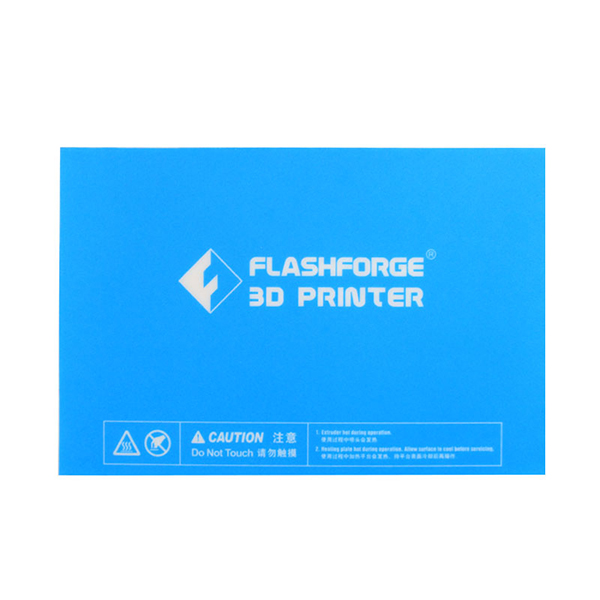

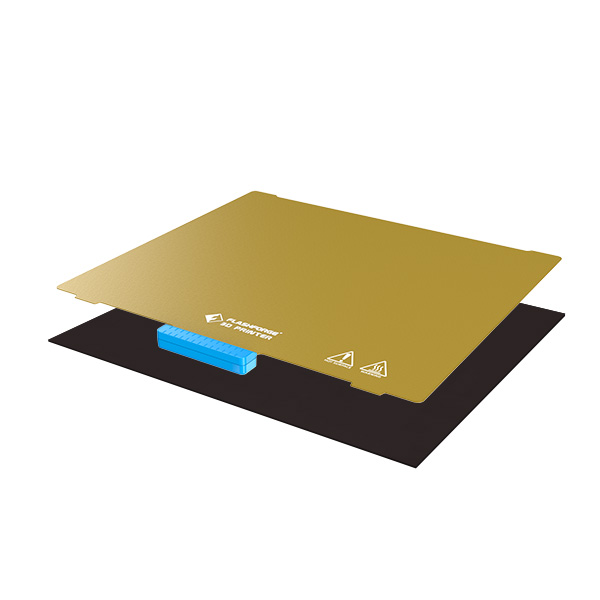

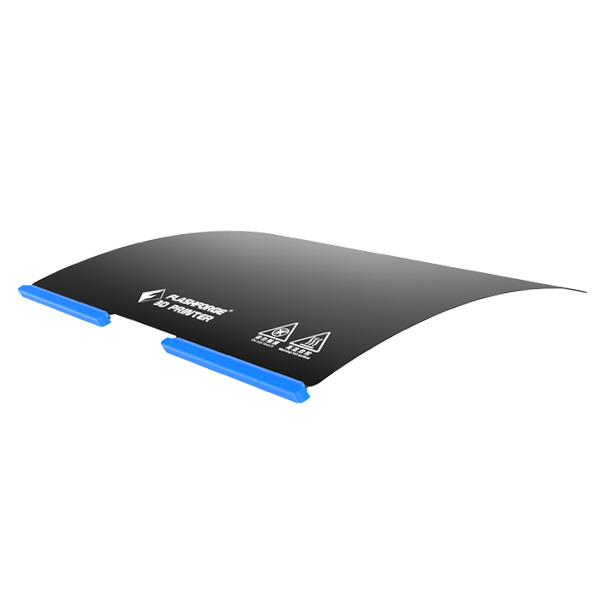

The Adventurer 3 Pro, a step up from the base model, accommodates a wider range of filament types. Besides ABS and PLA, it can handle PC, PETG, PETG-CF, PLA-CF, and ASA filaments. This expanded filament compatibility offers more versatility for different types of printing projects. The 3 Pro model boasts a crystal glass build plate, known for its superior adhesion and flatness, further enhancing the printing precision.

- Printing speed: 10~100mm/s; 500mm/s2

- Compatible with: PLA/ABS/SPC/PETG/PETG-CF/PLA-CF/ASA

- Build plate: crystal glass plate

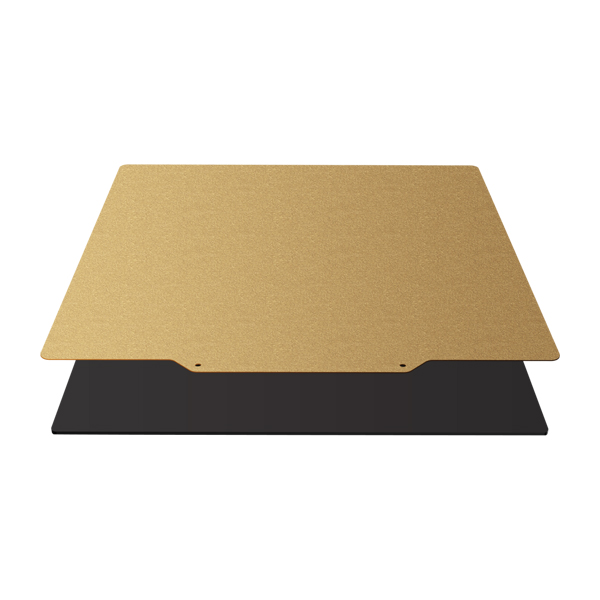

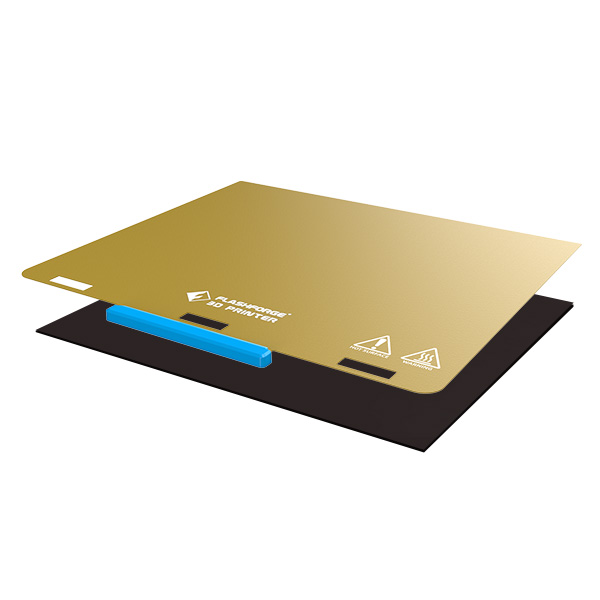

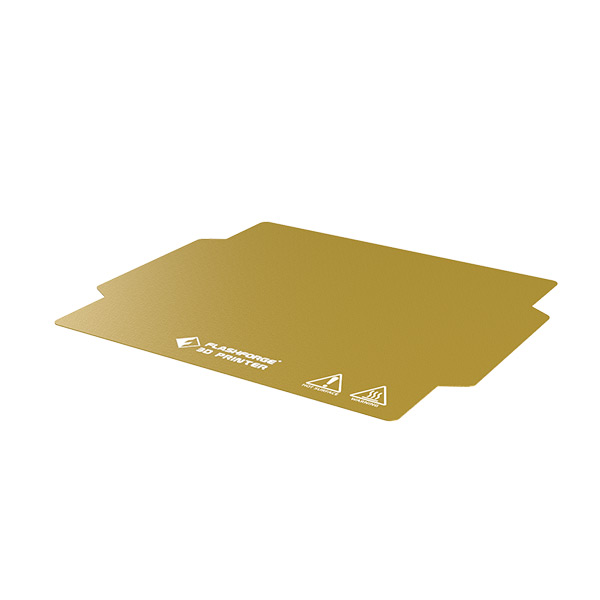

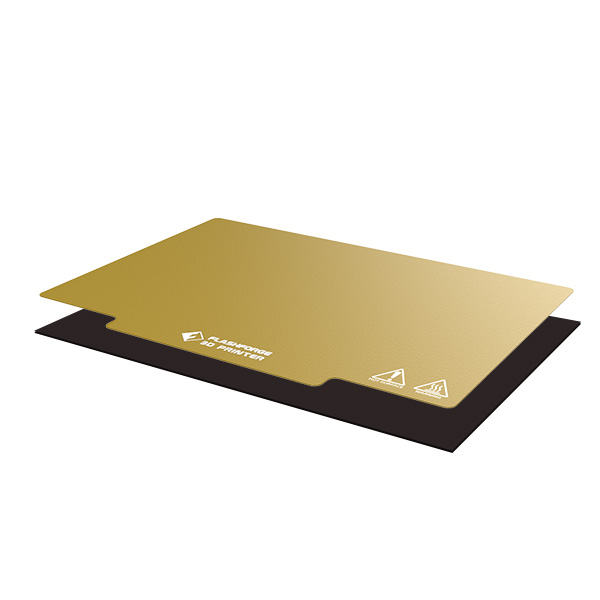

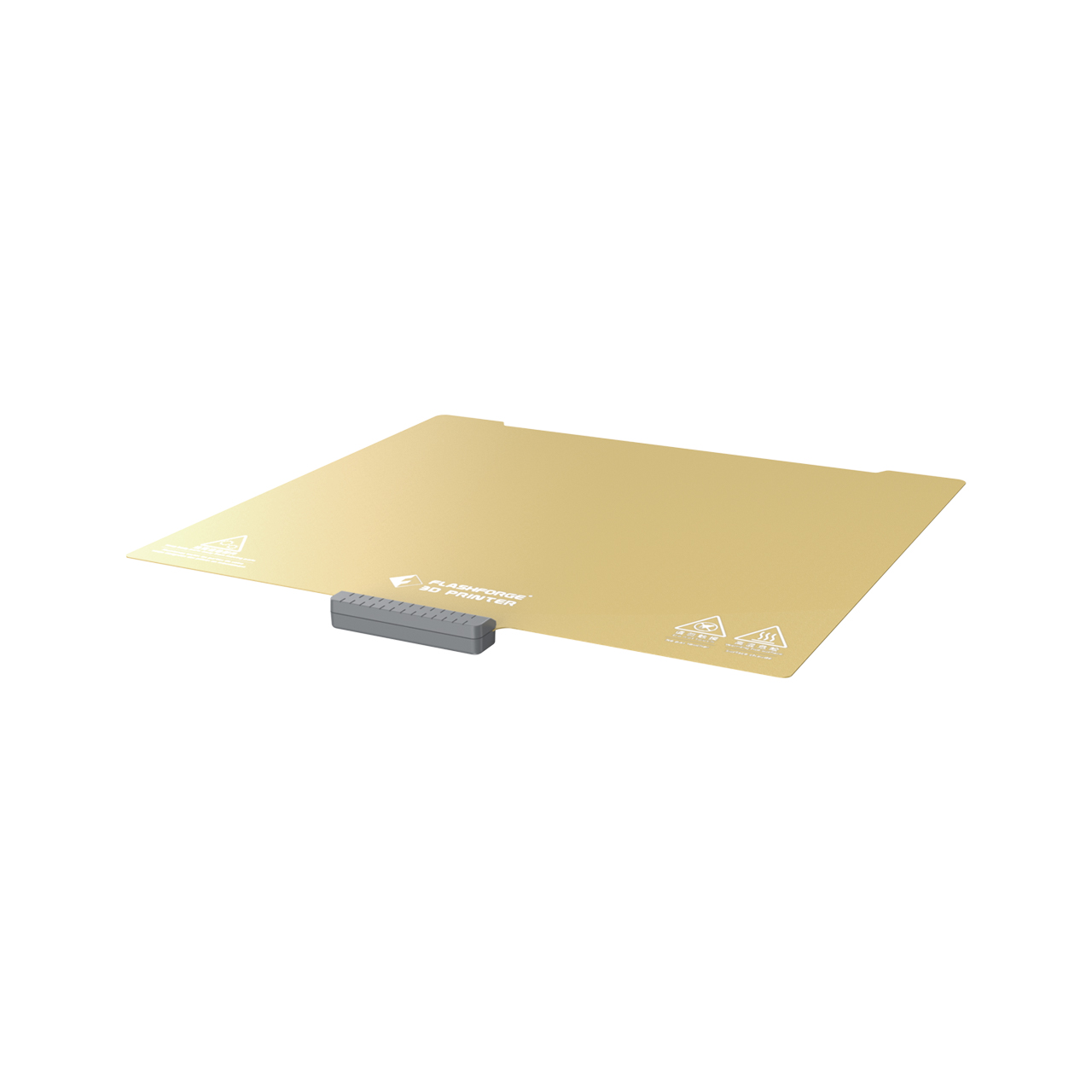

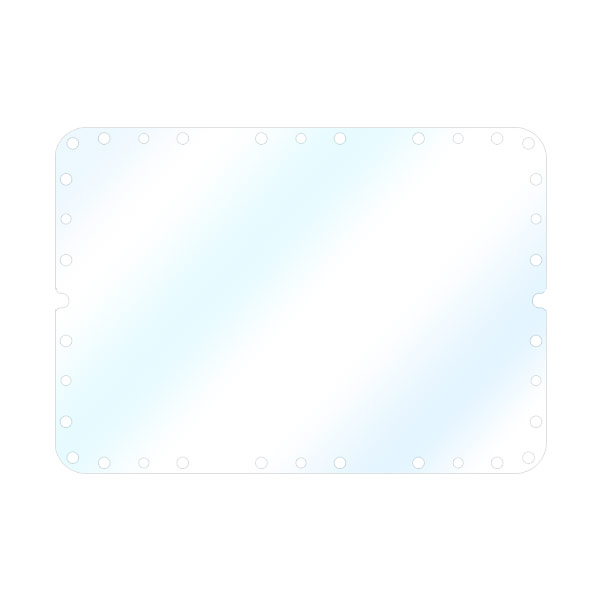

Finally, we have the Adventurer 3 Pro 2. This top-tier model in the series outperforms the others with a significantly faster printing speed acceleration of 10~300mm/s and 10000mm/s2. This allows for quicker project completion without sacrificing print quality. The Adventurer 3 Pro 2 supports the same broad range of filament types as the Adventurer 3 Pro but stands out with its PEI build plate. Combining the benefits of other build plates, PEI offers excellent adhesion and eases print removal post-completion.

- Printing speed: 10~300mm/s; 10000mm/s2

- Compatible with: PLA/ABS/SPC/PETG/PETG-CF/PLA-CF/ASA

- Build plate: PEI steel plate

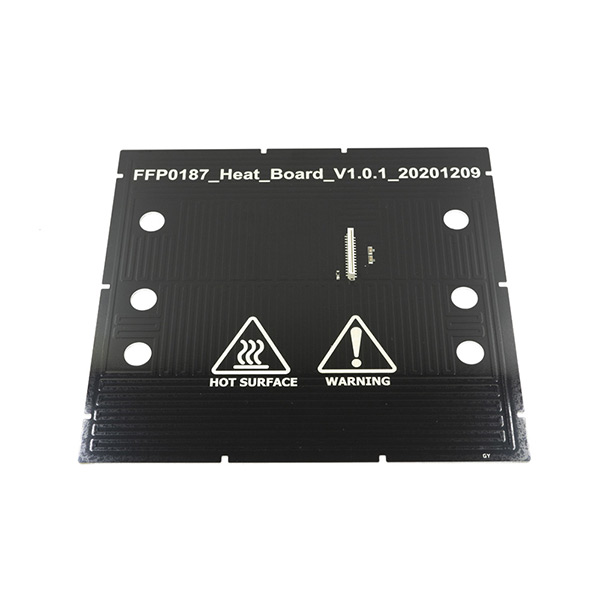

Here is a specific comparison of the 3 models of 3D printers in build plate type. It's important to note that each type of build plate has its own advantages and may be more suitable for specific printing needs or materials. Consider the specific requirements of your printing projects and materials to choose the most appropriate build plate option.

Flexible Build Plate: Easy model removal: The flexibility of the build plate allows for effortless bending or flexing, making it simpler to remove printed models without the need of scraper.

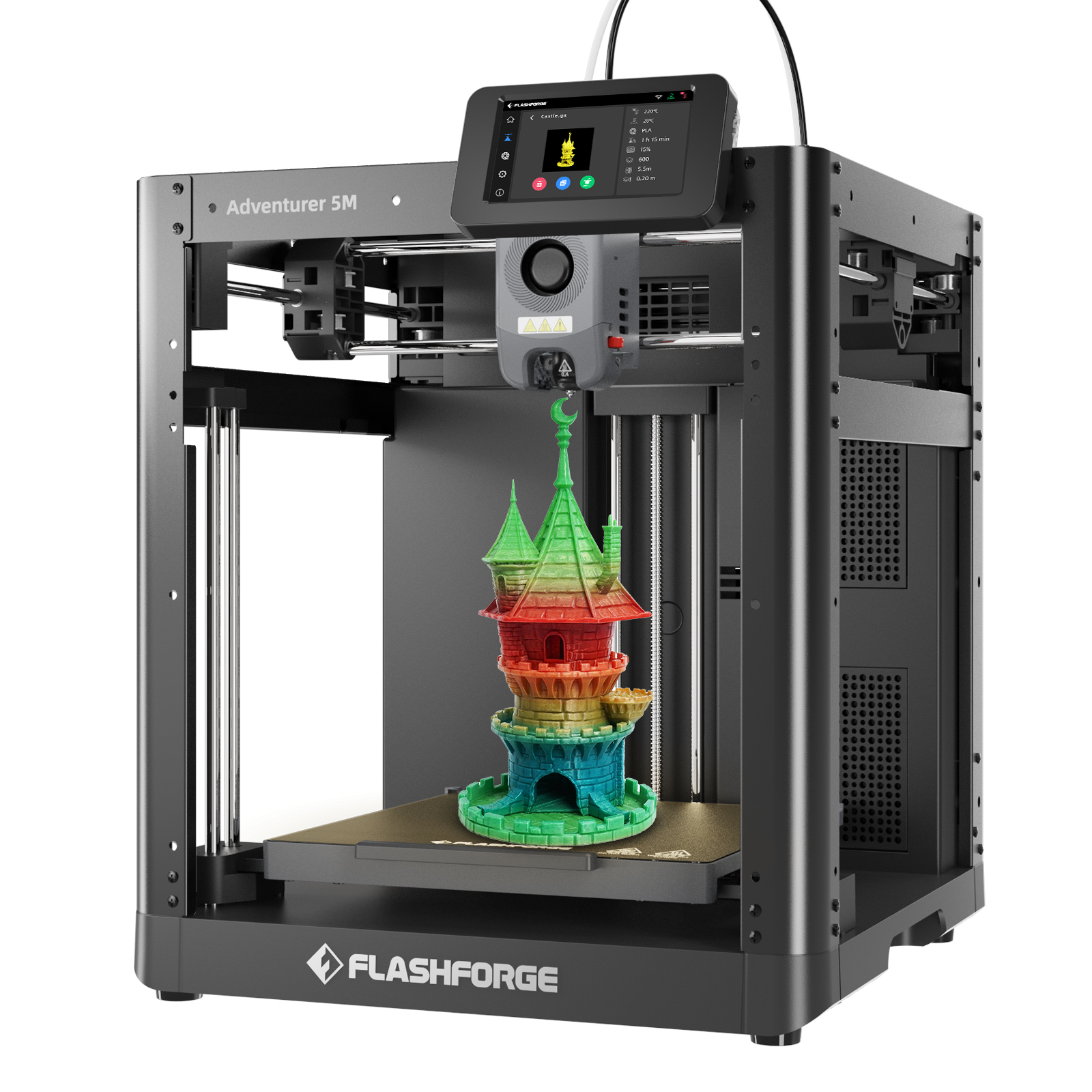

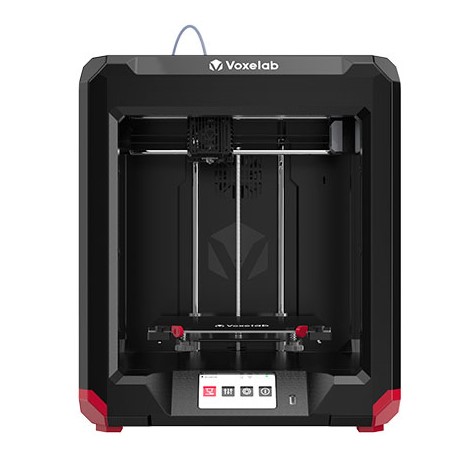

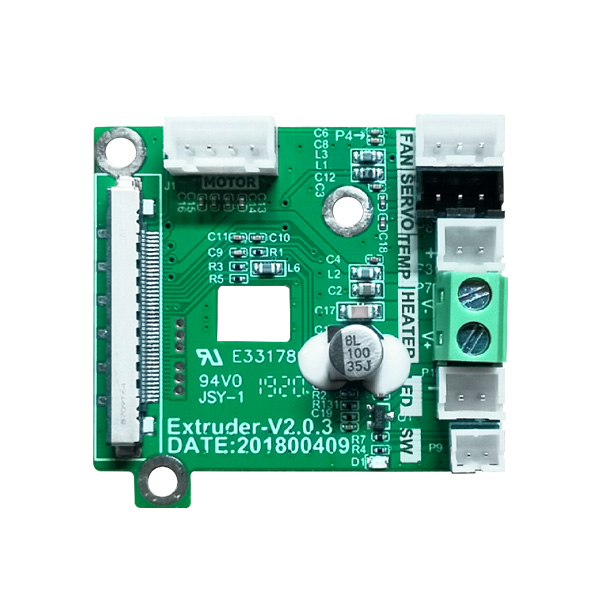

▲Flexible build plate of Adventurer 3

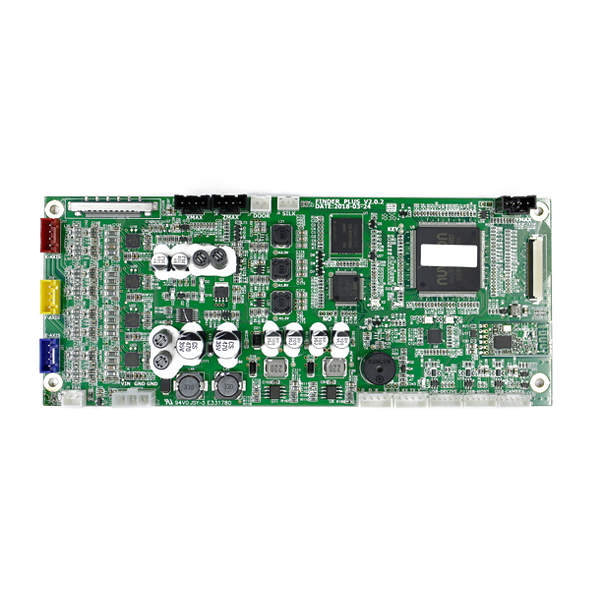

Carbon Fiber Crystal Glass Build Plate: Excellent first layer results: smoother surface; enabling better grip and reducing the likelihood of print failures or warping.

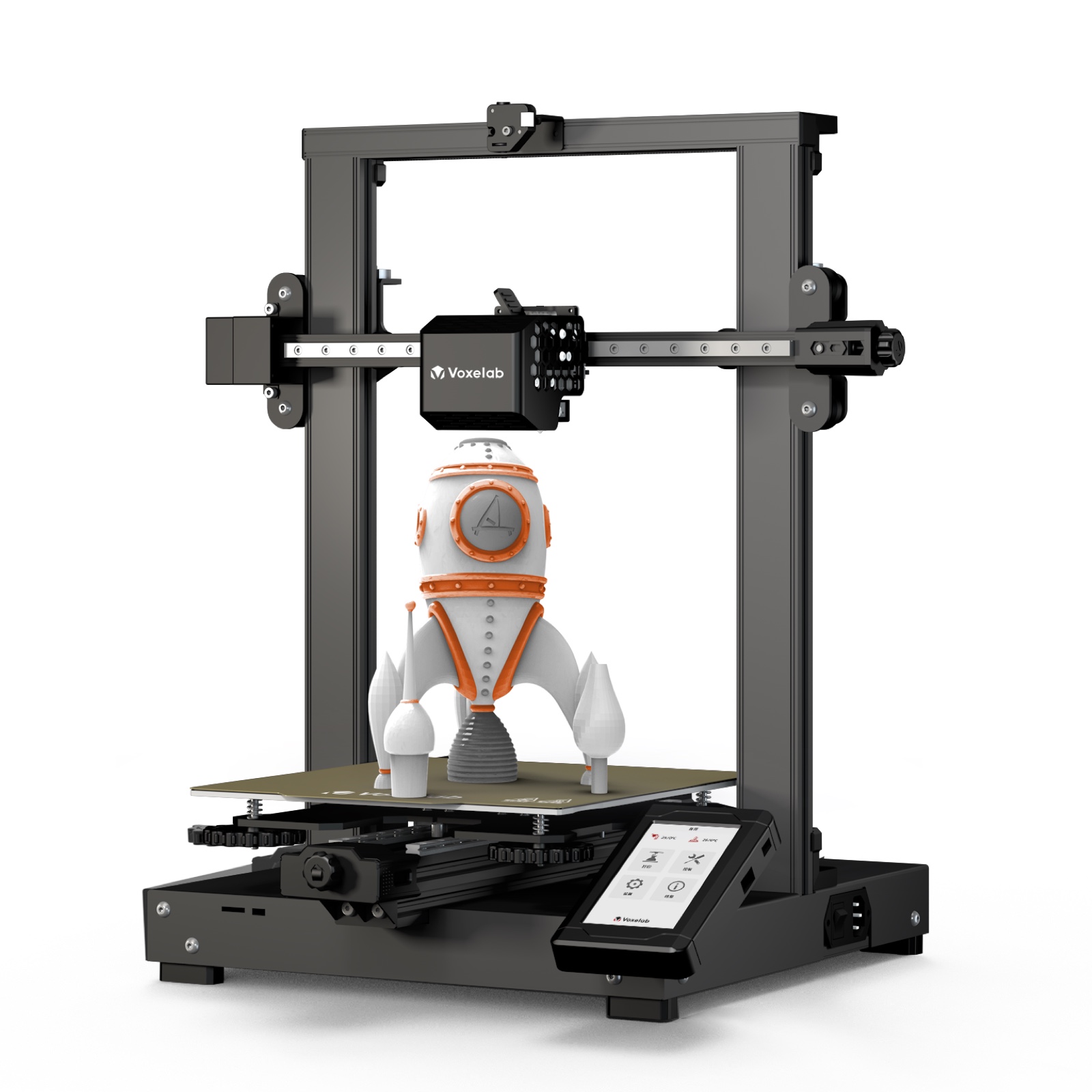

▲Glass build plate of Adventurer 3 Pro

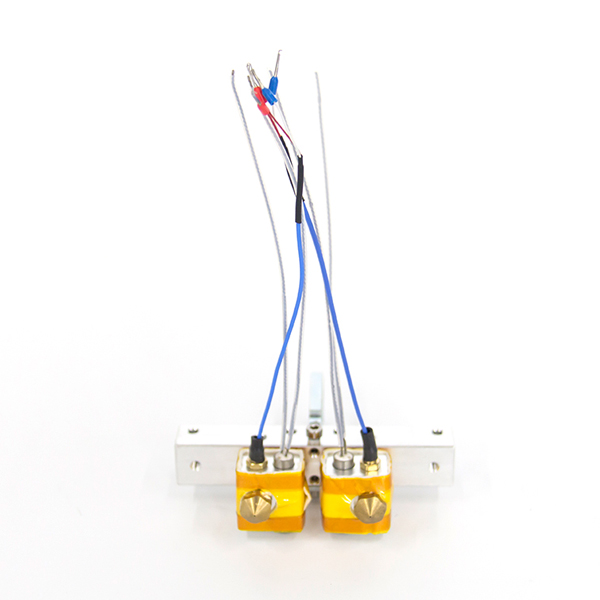

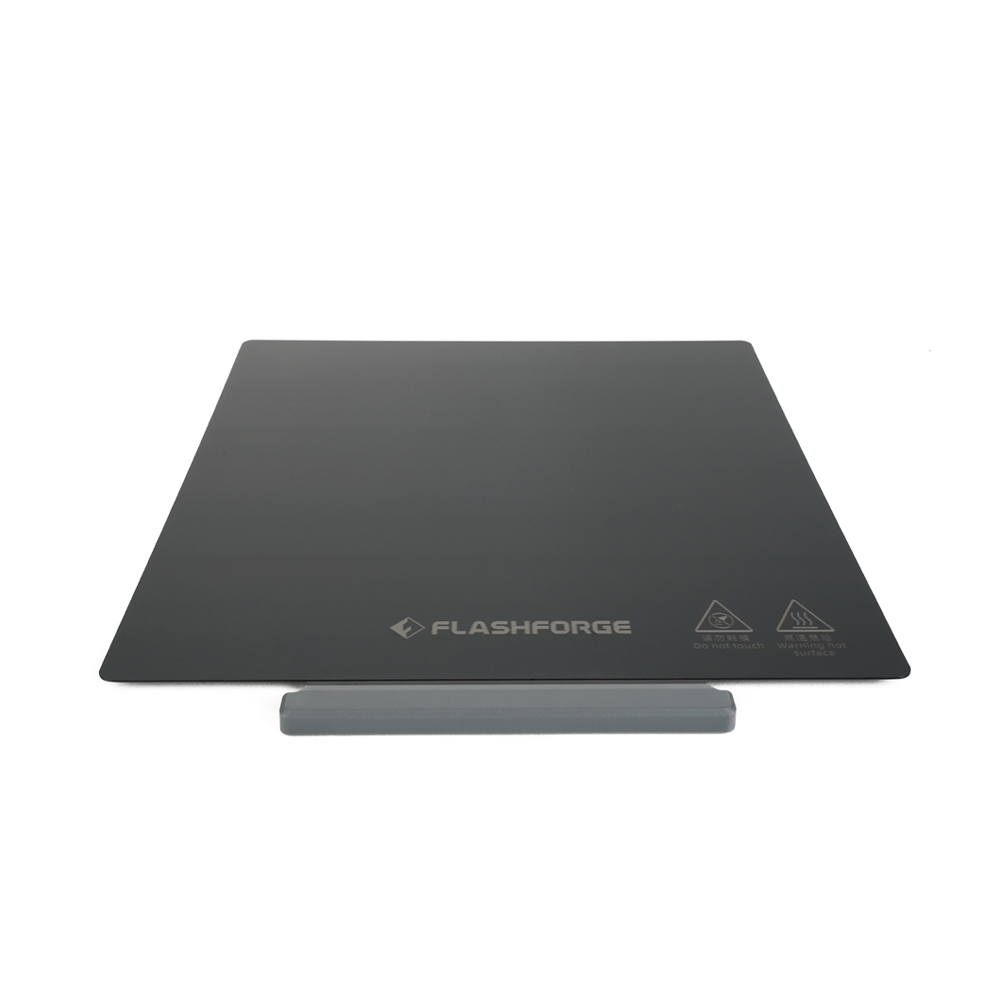

PEI Steel Build Plate: High adhesion properties: PEI (Polyetherimide) offers exceptional print bed adhesion, ensuring that printed models adhere firmly to the build plate throughout the printing process, hence high-precision printout results.

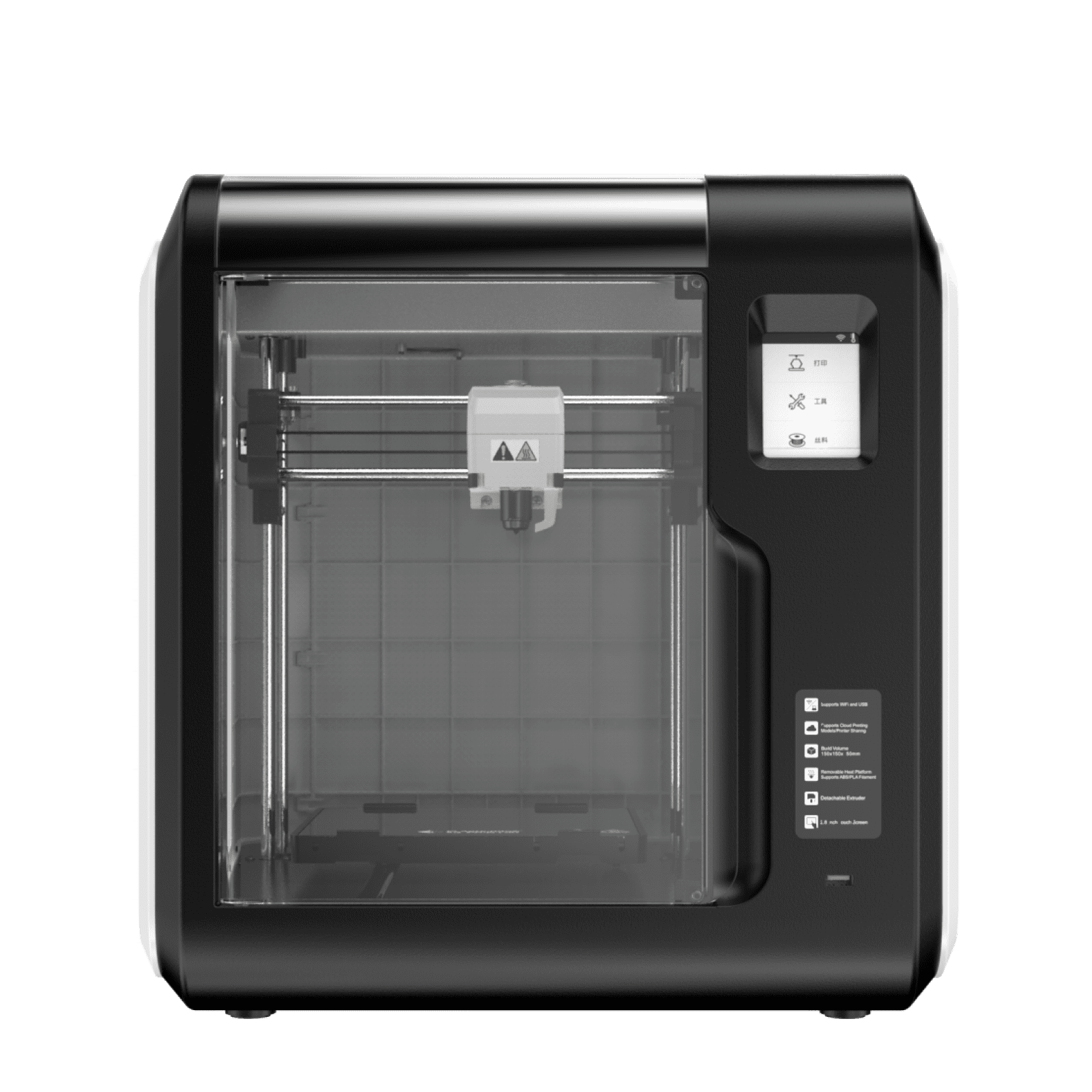

▲PEI build plate of Adventurer 3 Pro 2

Clarifying your requirements for the 3D printers

While the Adventurer 3 series is versatile, it is important to note that its smaller build volume and entry-level features may not be suitable for large-scale production or highly advanced applications. For such purposes, other models or industrial-grade 3D printers may be more appropriate.

Ultimately, the best choice from the Adventurer 3 series depends on your specific 3D printing requirements. It's a matter of matching your needs to the right model – be it the Adventurer 3, Adventurer 3 Pro, or the Adventurer 3 Pro 2. Flashforgeshop wish you happy printing!