In the furniture business, the design process has always taken a lot of time and money. Now, furniture designing is more efficient, simpler, and less expensive thanks to large-scale 3D printing. Lightweight prototypes can be made quickly and cheaply with 3D printing.

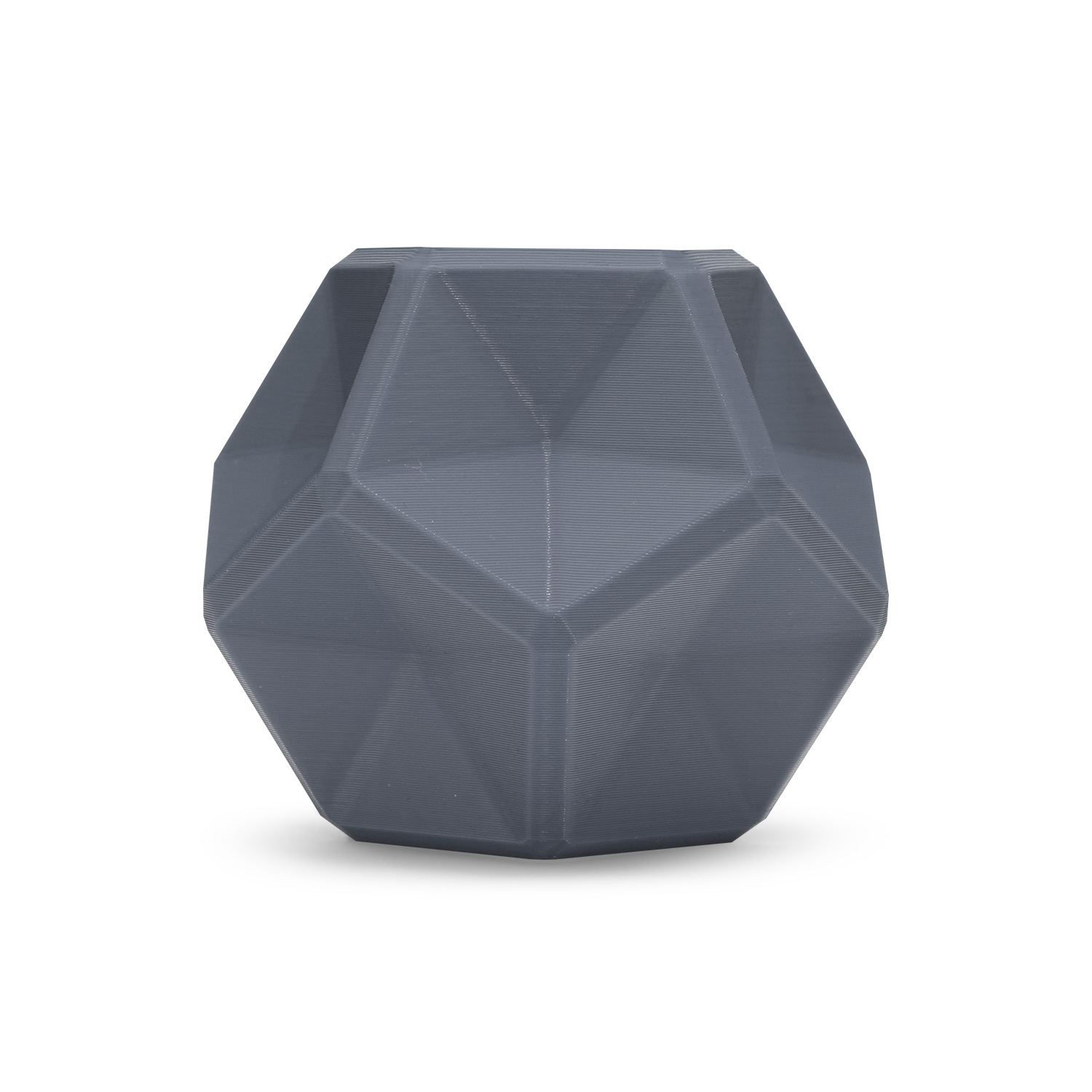

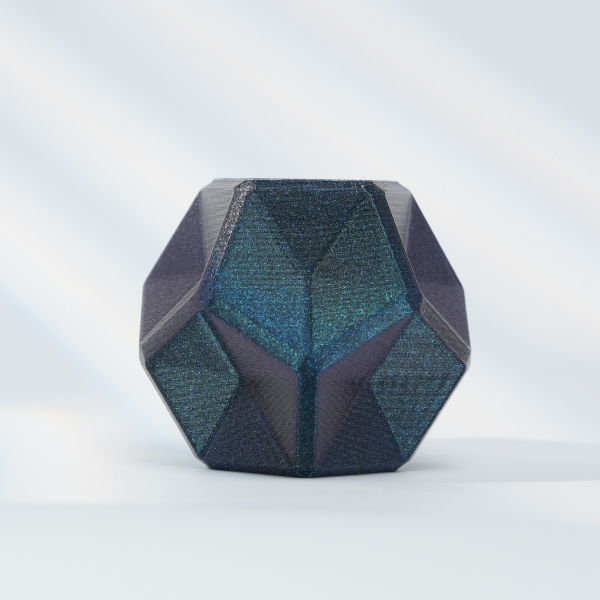

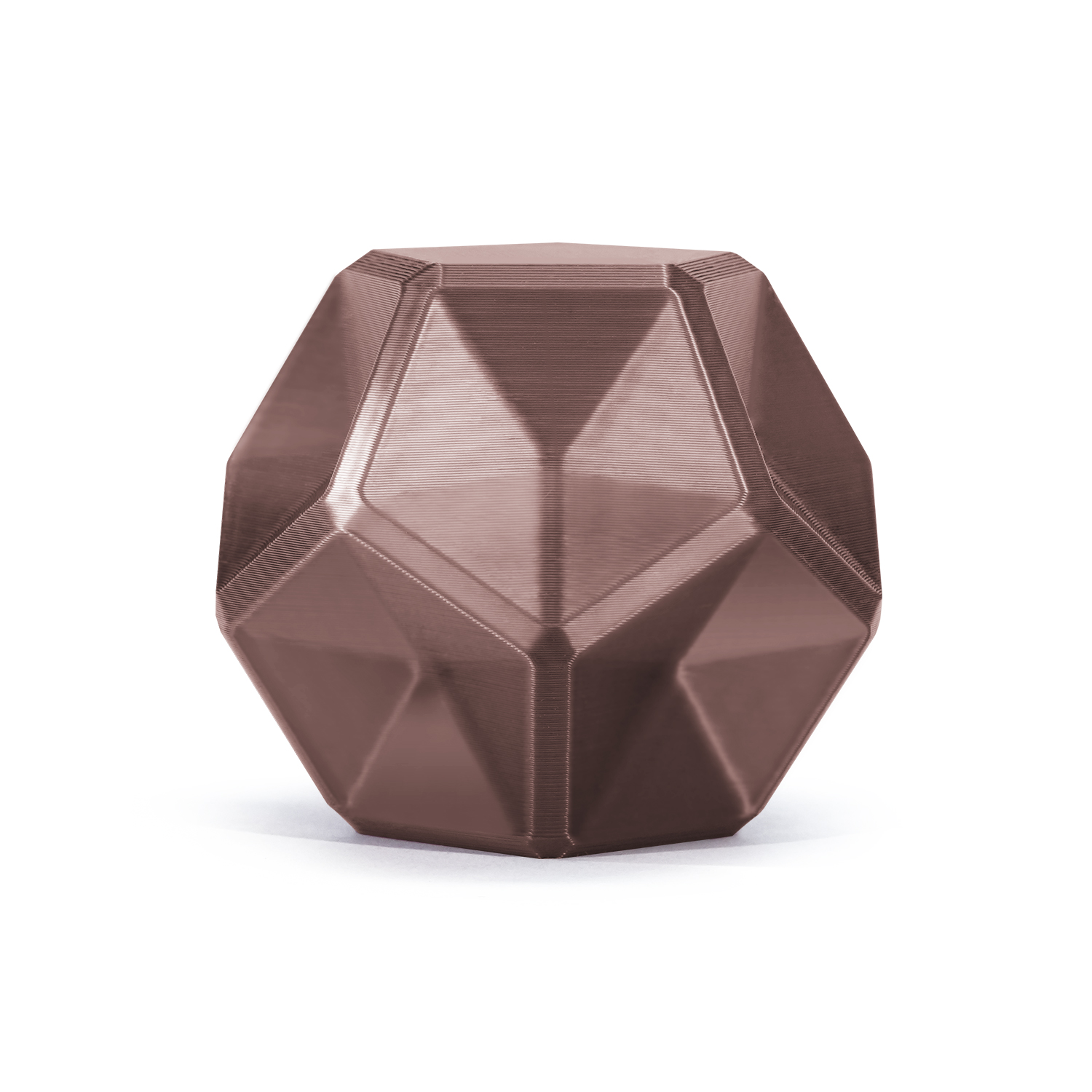

3D-printed design objects give product designers, interior designers, and artists new ways to show off their work and design ideas. This technology makes designs easy to understand and look at in detail from any angle, whether for the legs of a table, chairs, or lamps.

Utilization of Large scale 3D Printing in the Molding of Complex Furniture

The present-day furniture manufacturing industry has benefited from 3D printing technology. First, this is clear when you look at how the mold-opening problem with some oddly shaped furniture was fixed by making the mold-making process less complicated.

For types of furniture like upholstered furniture, metal furniture, and injection-molded furniture, some furniture must go through plastic molding or metal casting processing. This step takes place during the prototype stage of furniture production.

Progression of Large scale 3D printers in Furniture

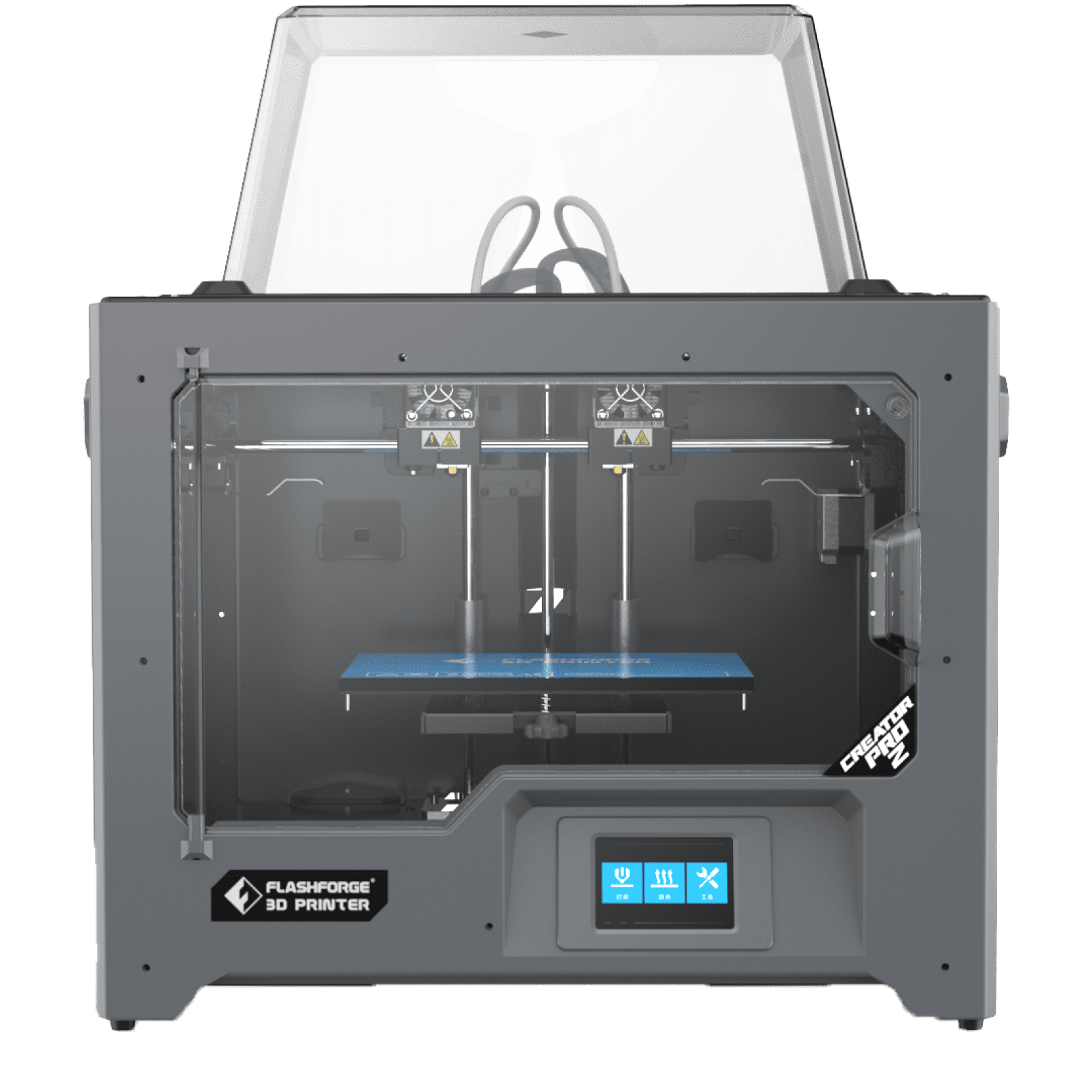

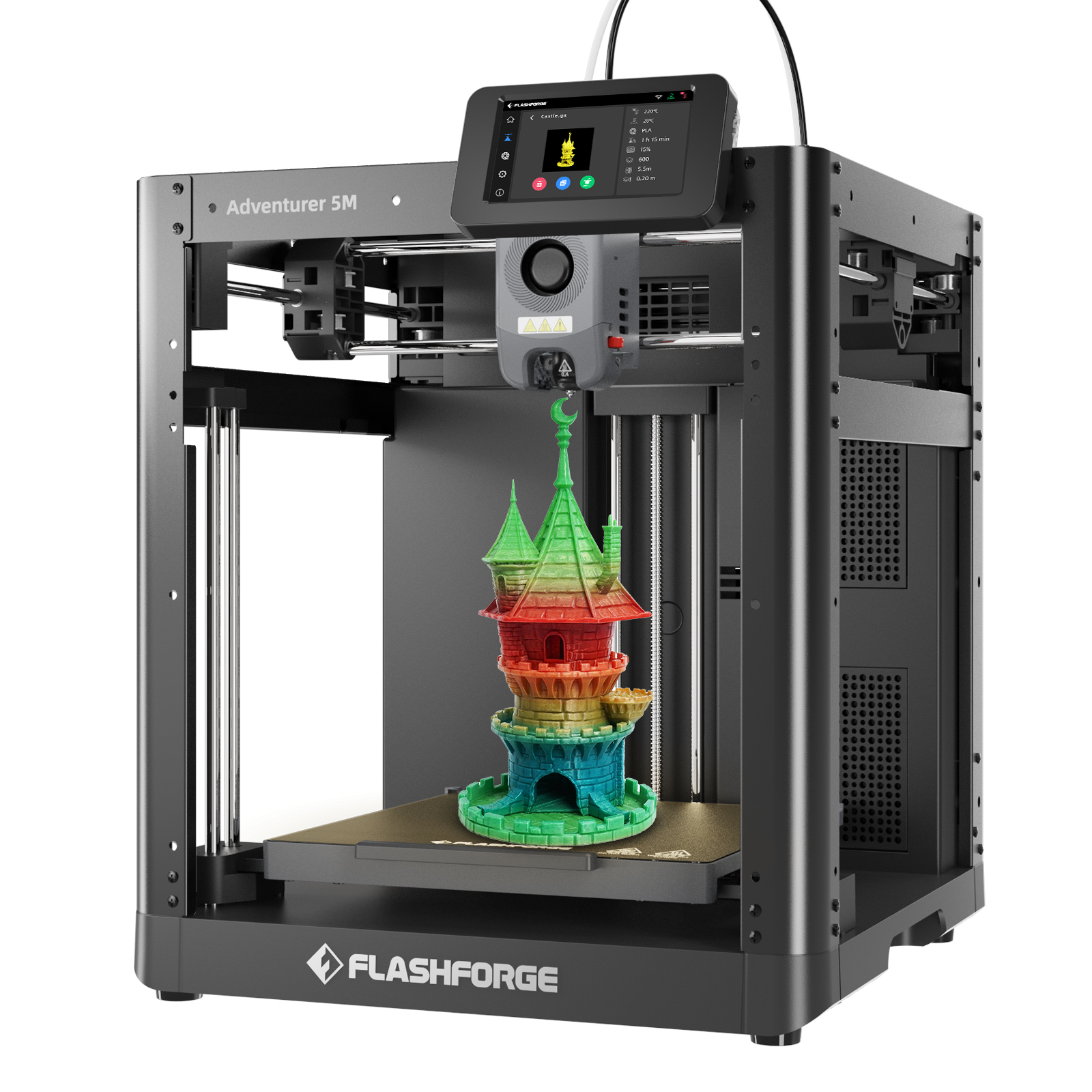

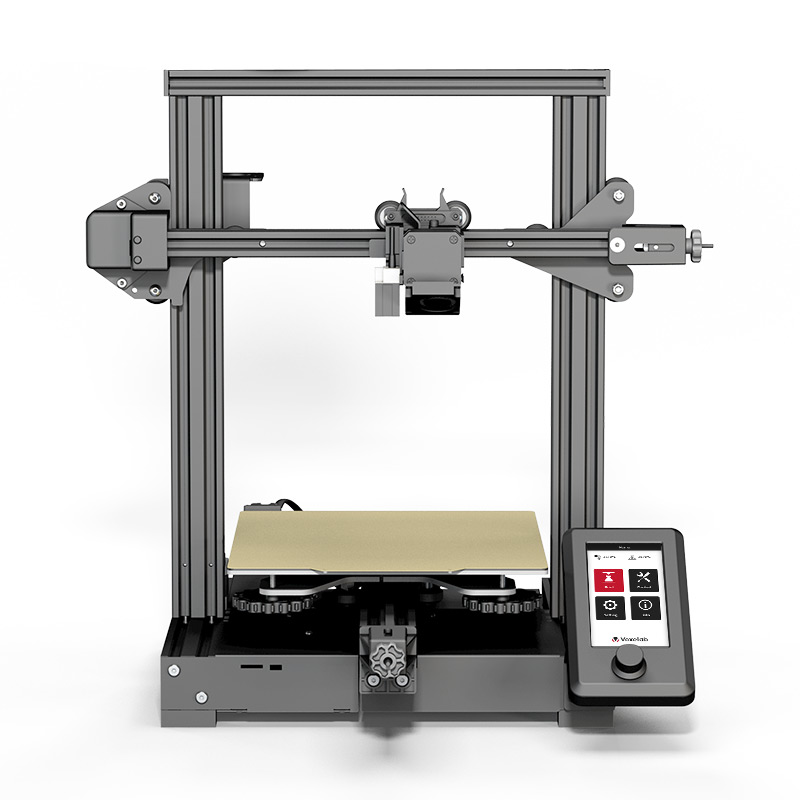

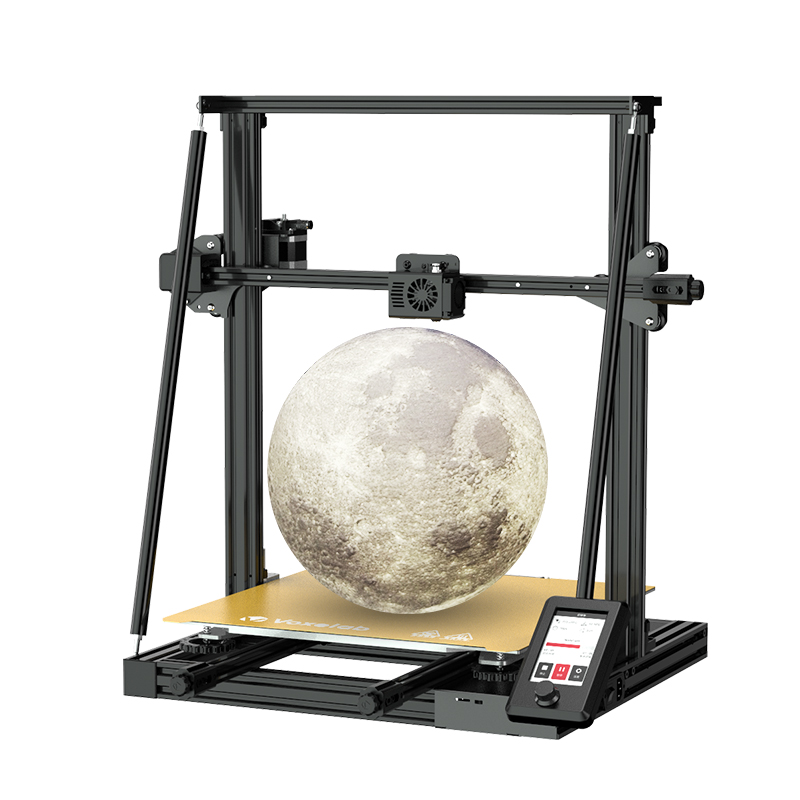

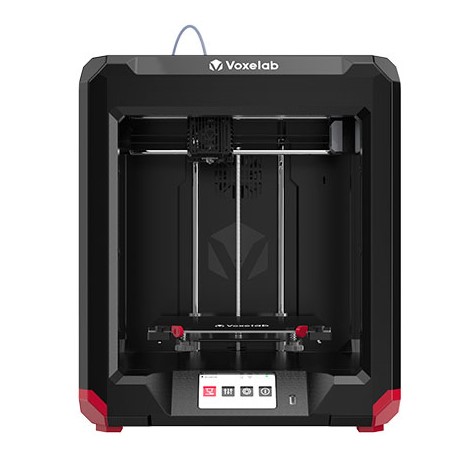

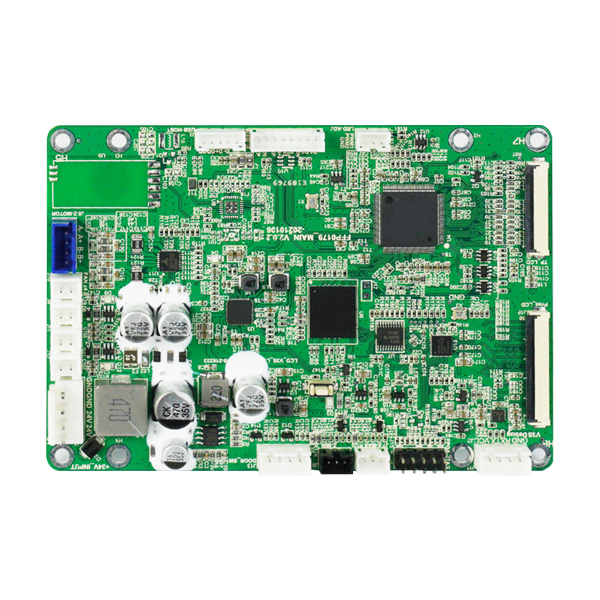

To print furniture, car parts, and architectural elements, a large-scale 3D printer is required. Large-format printing is used for its size, but there are other reasons. The following is an overview of some of the less obvious factors:

Unibody Parts: Producers can frequently create large objects using conventional assembly techniques. However, producing these items as a single solid piece—which a large 3D printer can only do—would improve their performance.

Weight reduction Large objects are typically made of wood, metal, or plastic that has been injection molded. The same objects will print much more. Consolidated assemblies also cost less because less material needs to be bought from different places. In addition to reducing the need for fasteners like nuts and bolts, the weight of large assemblies is also reduced when they are broken down into single components.

Faster Development: Large prototypes can be printed much more quickly than they could be made in any other way because 3D printing requires virtually no setup steps. Large objects may take a while to print, but depending on the details, it might be quicker to do production runs of large objects by skipping the time-consuming tooling step.

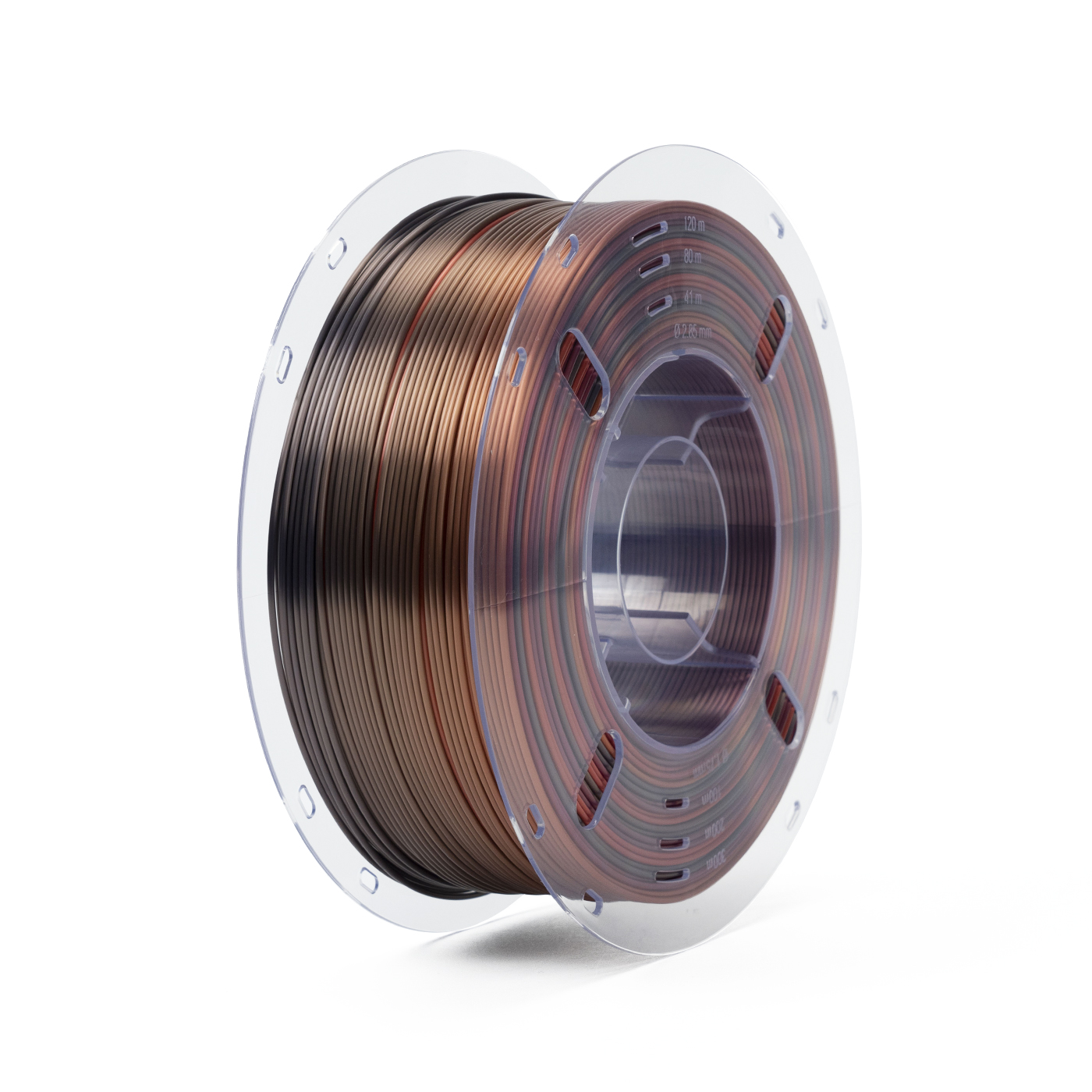

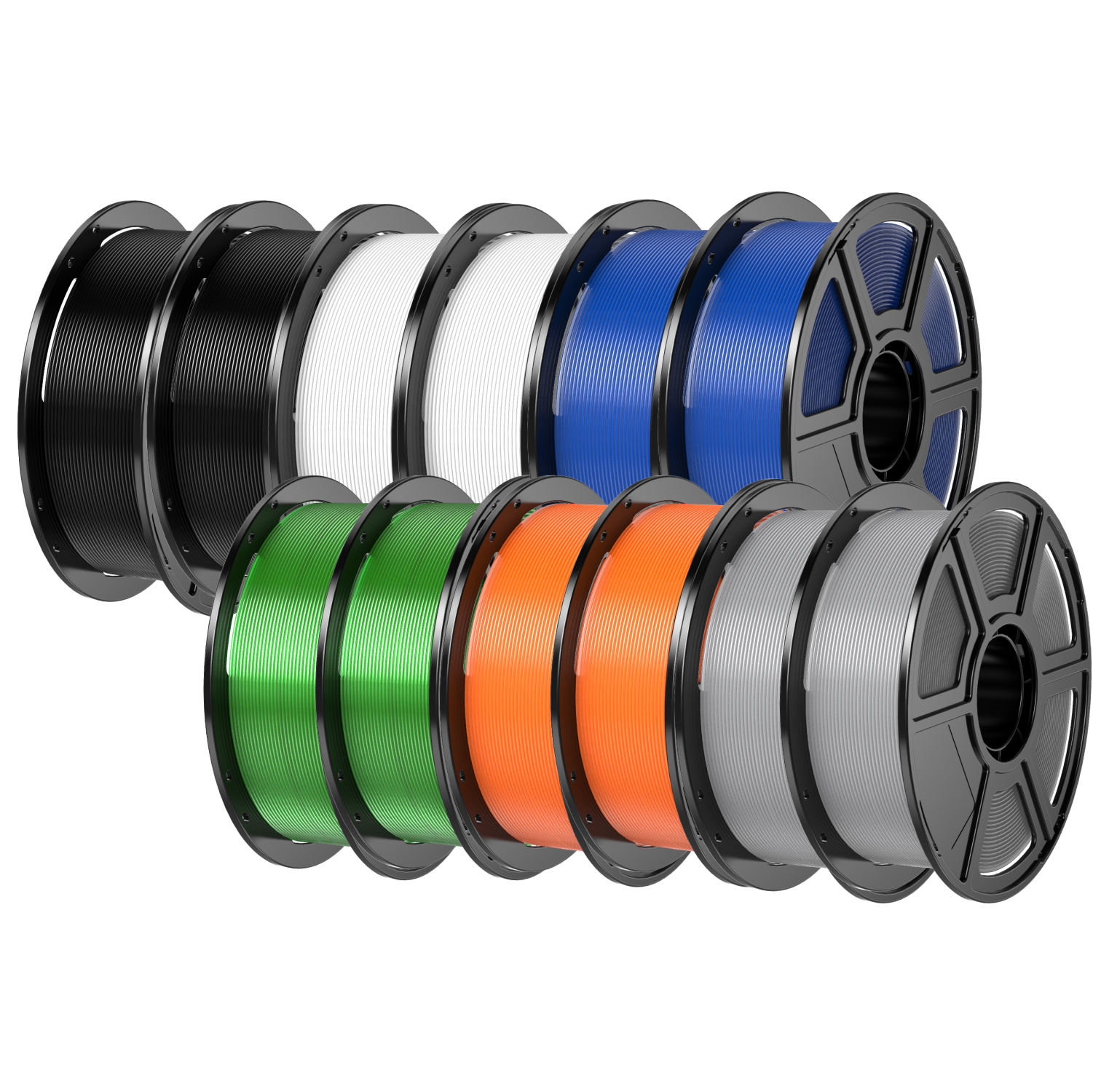

Cost Saving: Large 3D printed parts can be almost entirely cost-competitive with conventionally manufactured parts due to higher tooling costs. Consolidated assemblies also cost less because less material needs to be bought from different places. Different 3D printing materials, such as product-detail/pla-vs-abs are used in furniture making.

Design freedom: Traditional manufacturing methods can't make many geometries, like internal channels and complex lattice structures. Such features are advantageous for many large objects, such as furniture, and large-scale 3D printers are the only way to implement those designs.

How could interior design be unaffected by new-age technology that can reach such a wide area?

Many architects and interior designers are using 3D printing in a big way to make new and unique designs that give a building's atmosphere a modern and global look. Let's look at how 3D printing changes how architects and interior designers solve everyday problems.

New Design Flexibilities

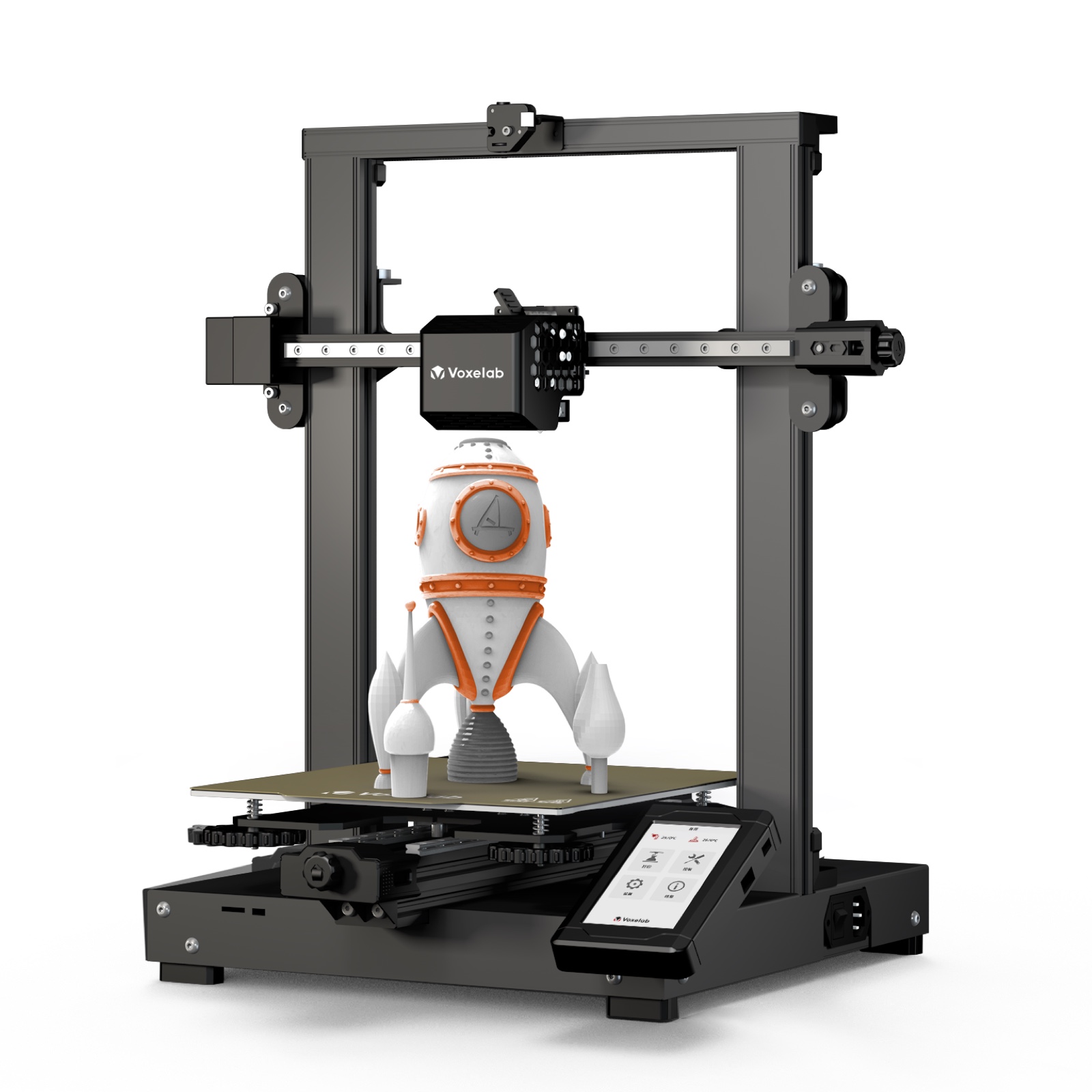

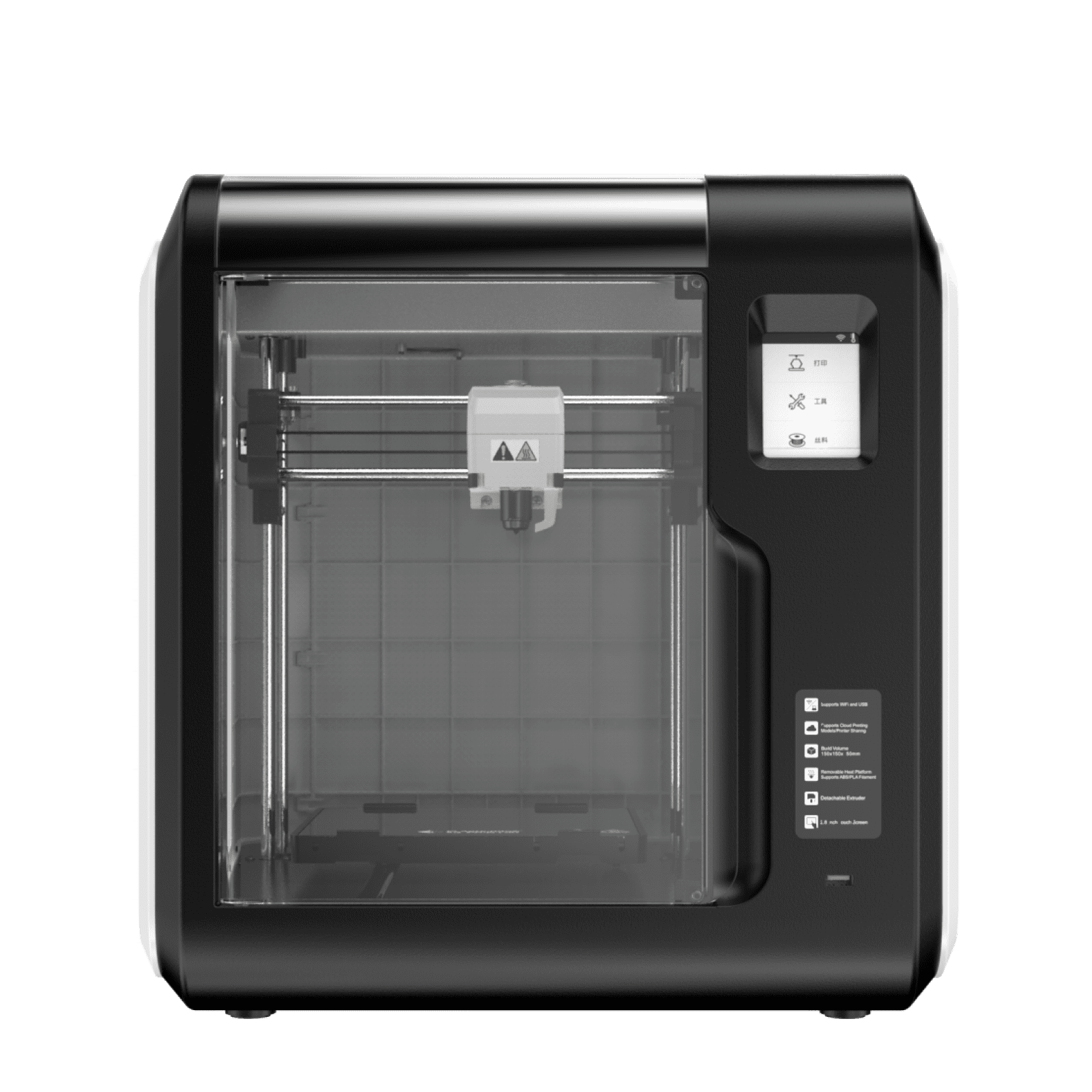

Due to the scalability of 3D printing, there are no longer any technical restrictions on the design of any object. They can use their creativity to develop new designs that couldn't be made before with traditional manufacturing methods. A single part can be produced using 3D printing in hours rather than the days or weeks required by more conventional methods.

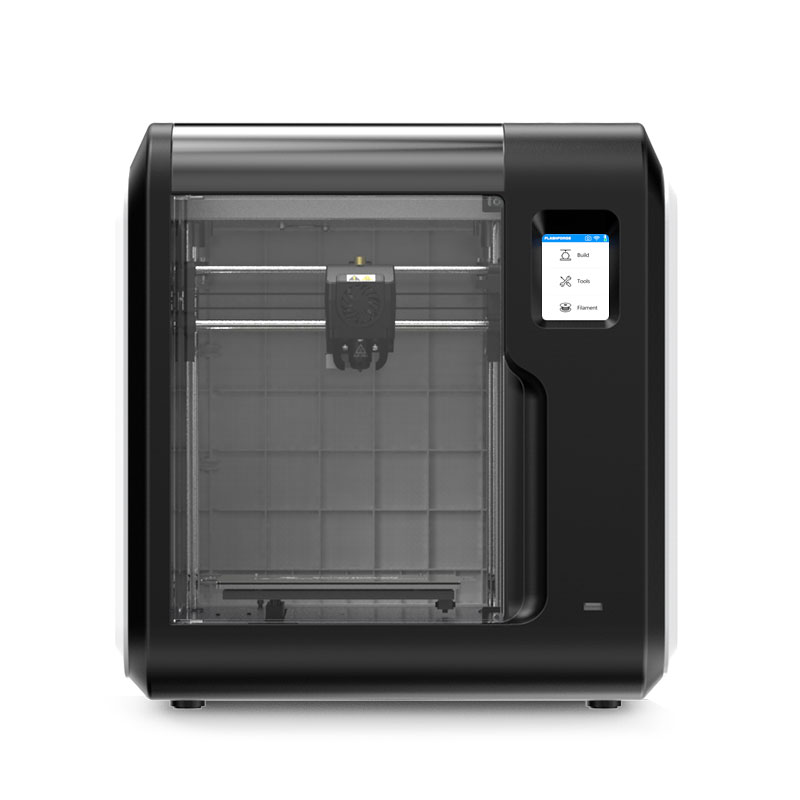

Availability of Technological setup

A simple 3D printing setup is simple to install in any workshop. Even if the designer works on larger items like furniture, it is simple to outsource the project. This has made it possible for many interior designers and architects to make furniture, fixtures, and other home decor based on what their clients want. This gives their work a truly elegant and unique look. They are no longer restricted to relying solely on what is offered in the market.

Production efficiency

With the 3D printer's accuracy and speed, it is now possible to create user-friendly designs with only what is needed, with the least amount of waste, and in the shortest amount of time. Also, each printed product or batch can be different, letting the designer try many different ideas until he finds the best one.

Options for customization

Interior designers can produce unique, customized designs for their clients using 3D printing programs. In today’s era, designers are now free to let customers select the product's color and size while maintaining the same design. 3D printing can change the look of already-made things to make them look better.

As 3D printing becomes more common, architects, interior designers, and other design professionals will likely change how they work on projects. Instead of relying on experience and what's on the market, the whole interior design industry will be rethought around customization.

The only criteria used going forward to complete the interior design will be the client's tastes and preferences.

Final Thought

Large-scale 3D printing has helped furniture and interior design in many ways and made our lives more comfortable. With this technology, we can make customized designs for our bedrooms and decorate them how we want! Our best-vetted expert teams will guide you more on this.